Gaskets or O-rings

Elastomer Gaskets – EPDM, Silicone & VITON®

All Advanced Couplings’ elastomer gaskets are designed and manufactured to give a smooth transition throughout the bore when fully assembled. To guarantee this degree of control, all Advanced Couplings’ Elastomer gaskets are produced to have a shore hardness of 75/85 IRHD. Gaskets are produced from compounds that conform to FDA code of regulations for rubber and rubber-like materials: Title 21, paragraph 177.2660. They also meet Class1 material classification of the 3A sanitary standards USDA and standard 51 of the NSF.

The Elastomer range of gaskets are colour coded to aid identification:

- EPDM =Black/Blue

- VITON®=Green

- Silicone =White/Clear

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

PTFE Solid (Teflon®) Gaskets

The Advanced Couplings range of PTFE solid gaskets are manufactured by machining from solid billets of virgin PTFE with a hardness of 60/65 shore D, guaranteeing precision components coupled with low porosity properties. Gaskets are produced from compounds that conform to FDA code of regulations for TEFLON® and Fluorocarbon resin materials : Title 21, paragraph 177.1550 for use in contact with foodstuffs. The gaskets also meet Class1 material classification of the 3A sanitary standards. The manufacturing process lends itself to offering solid gaskets in special sizes to suit all customers requirements and most requests for non-standard components can be accommodated.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

PTFE Envelope (Teflon®) Gaskets

Envelope gaskets are of a composite construction being a PTFE (TEFLON®) outer, with a VITON® filler as standard. The design offers a seal which has a degree of elasticity giving good sealing properties coupled with flexibility. The PTFE (TEFLON®) element of the gasket is produced to have a hardness of 60/65 shore D, and is manufactured from a solid billet of virgin PTFE (TEFLON®). The gasket is designed to minimise the effects of stress cracking in the product contact area, thus adding aseptic qualities to the sealing system. Envelope gaskets are produced solely from compounds that conform to FDA code of regulations for TEFLON® and Fluorocarbon resin materials : Title 21, paragraph 177.1550 for use in contact with foodstuffs, the gaskets also meet Class1 material classification of the 3A sanitary standards. The manufacturing process lends itself to offering solid gaskets in special sizes to suit all customers requirements and most requests for non-standard components and variations on filler materials can also be accommodated.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

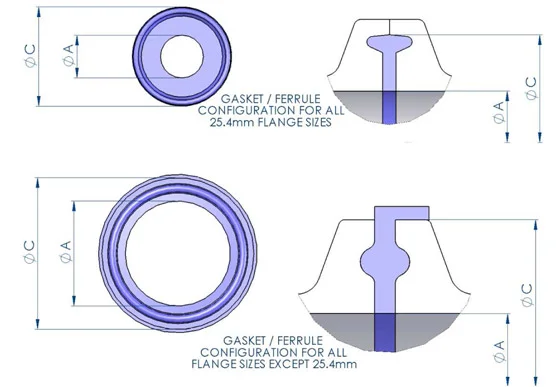

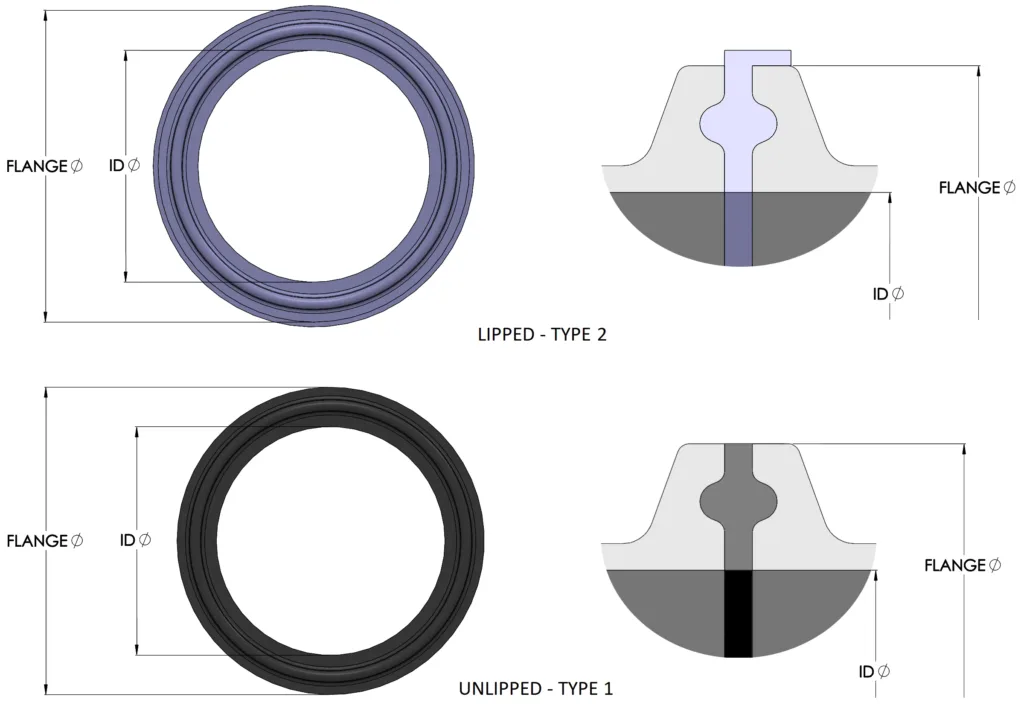

Manufacturing Standards of Gaskets

Advanced Couplings gaskets are manufactured for use in the Food & Dairy, Chemical and Pharmaceutical industries where standard tube/pipe couplings are required. All Advanced Couplings gaskets are FDA approved and are supplied as Type 2 Lipped as standard, aiding the ease of assembly. Advanced Couplings stock a full range of gasket sizes and materials to suit all the popular standards listed as below.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

Available Gasket Standards

- BS4825-3 Gaskets – These gaskets conform to a British Standard that is often referenced in applications within the Food & Dairy, Chemical, and Pharmaceutical industries.

- BS Schedule 5 Gaskets – These are designed according to a specific thickness schedule, among the lighter and thinner options.

- BS Schedule 10 Gaskets – Similar to Schedule 5, but typically heavier and thicker, suited for different applications.

- BS Schedule 40 Gaskets – A standard for an even thicker and heavier type of piping, with gaskets to match.

- DIN 32676 Standard Gaskets – Gaskets made according to the German Institute for Standardization (DIN), which are regularly used in European markets.

- DIN 32676 Non-Standard Gaskets – Custom gaskets that do not necessarily conform to the standard DIN measurements but are based on the same foundational specifications.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

Additional Gasket Standards

- ISO 1127 Series 1 Gaskets – Gaskets created per the International Organization for Standardization, specific to Series 1.

- ISO 1127 Variations Gaskets – Variation gaskets that are based on the ISO 1127 standard but have some differences or modifications.

- ISO 2037 Series 1 Gaskets – Another set of ISO standard gaskets, belonging to Series 1 of a particular ISO standard.

- ISO 2037 Series 2 Gaskets – Similarly, these belong to Series 2 and are likely to have different specifications or applications compared to Series 1.

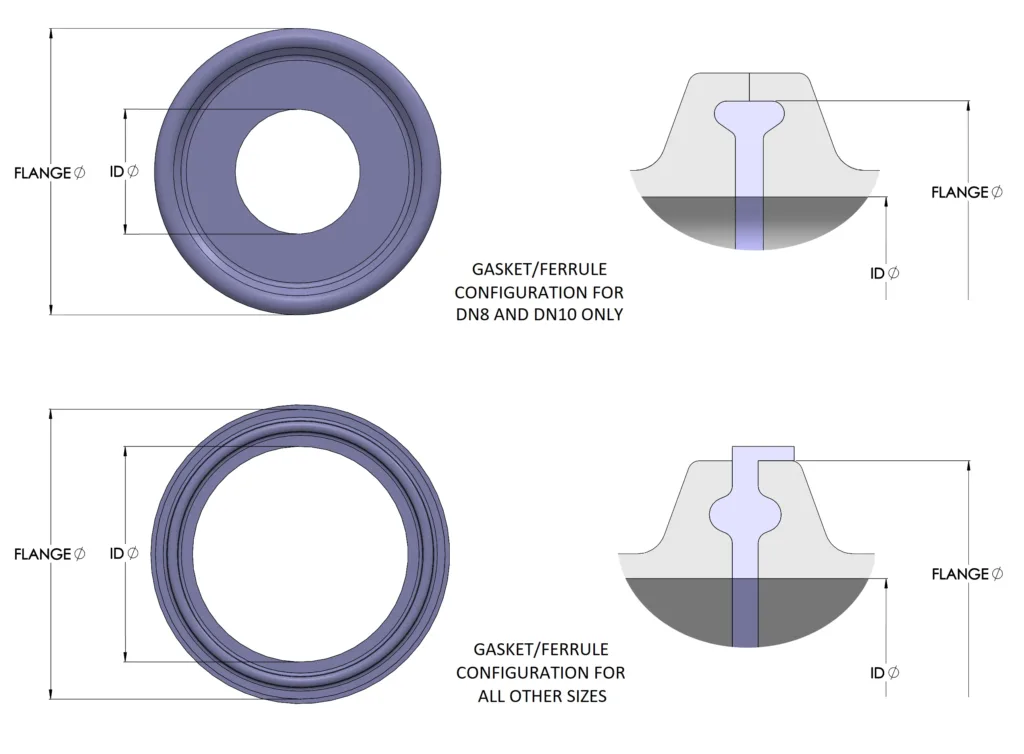

- Mini Series – Ultra Bore – Metric Gaskets – Small-sized gaskets designed for precise, high-tolerance applications, with metric dimension specifications.

- Mini Series – Ultra Bore – Imperial Gaskets – Much like the metric version, except these are sized according to imperial measurement standards.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!