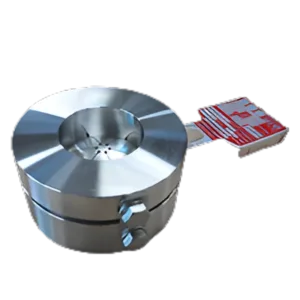

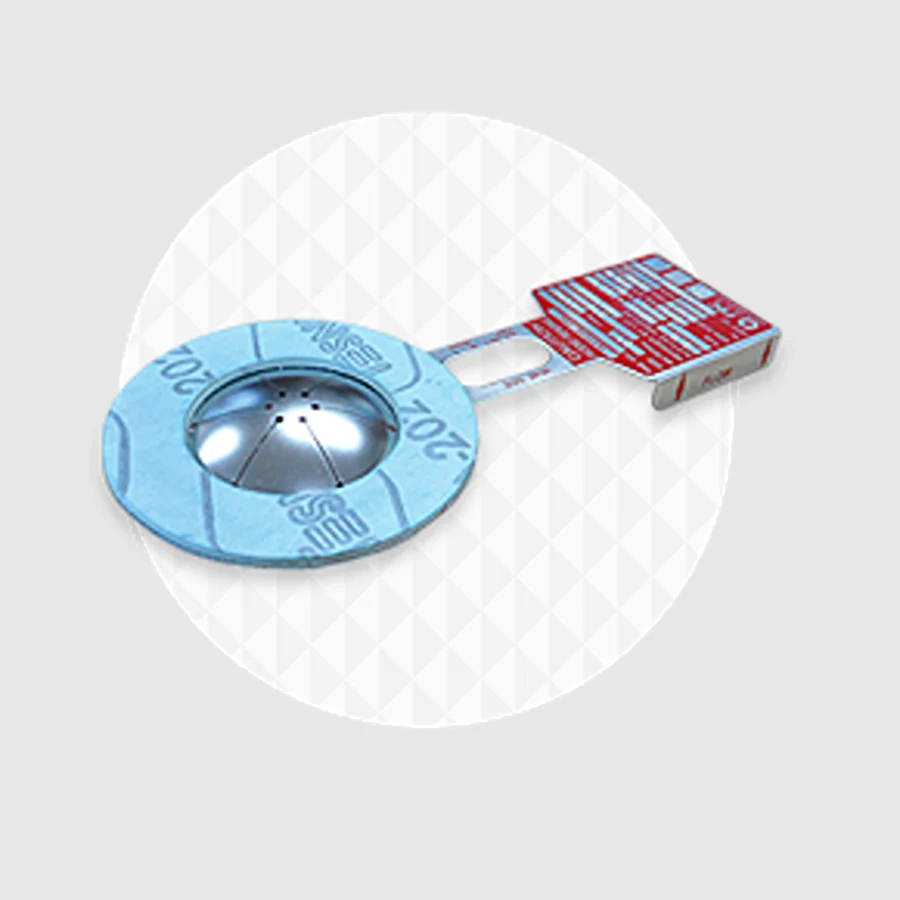

KSRC Composite Rupture Disc with Holder

- Suitable for liquid and steam media

- Counterpressure, vacuum, pulsation conditions compatibility

- Vacuum Support option available

- Precise rupture performance

- Reliability for medium to high pressure

- Corrosion resistance varies with Seal disc material

- Temperature range limited by Seal disc material

- Composite Dome Sloped Seat Type design

- Used with FDC standard holder installation

- Structure: Top disc, Seal disc, Vacuum disc

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!