Celebrating 25 Years 1999-2024

Explosion Isolation Diverters

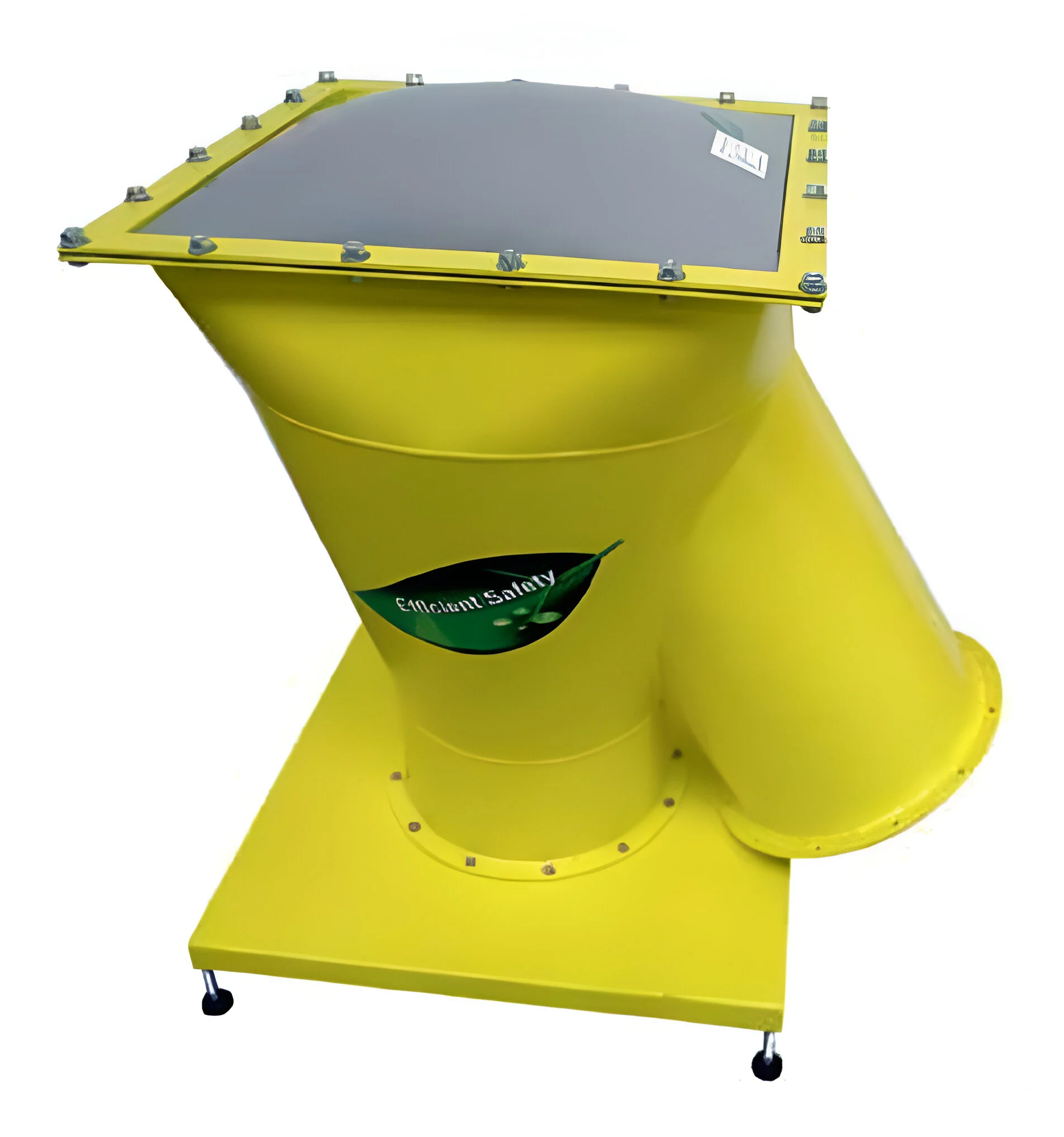

IEP-Brilex Explosion Diverter

- Enables bidirectional explosion protection.

- Meets DIN EN 16020:2011 safety standards.

- Reduces pressure losses by over 60%.

- Efficiency comparable to non-return valves.

- Offers enhanced flame suppression capabilities.

- Designed to minimize system pressure drops.

- Incorporates explosion vents tested for extreme conditions.

- BRILEX GE explosion vents provide high vacuum resistance.

- Ensures reliable protection with durable vent designs.

- Suitable for a wide range of dimensions and system sizes.

WANT MORE TECHNICAL DETAILS? DOWNLOAD OUR DATASHEET.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

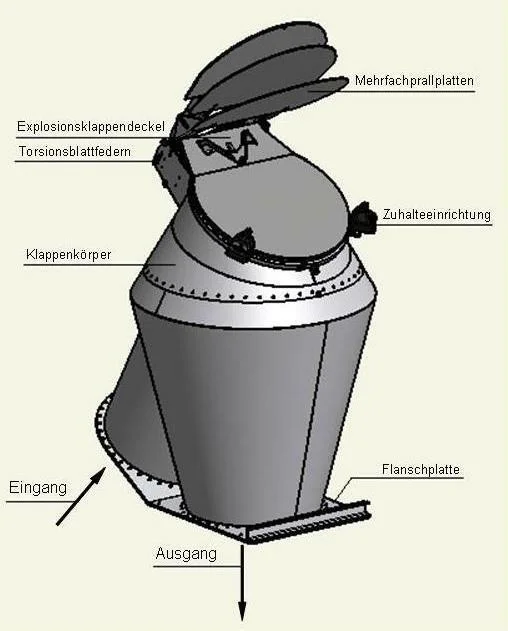

Thorwesten Vent – Type DES – Explosion Diverter

- Vertical orientation of explosion diverter

- Max propagation-induced pressure shock wave velocity: 520 – 770 m/s depending on model

- Total weight ranges: 55 kg to 345 kg

- Effective vent area ranges from 0.0078 m² to 0.077 m²

- Max reduced explosion pressure: 3 bar

- Dust explosion classification: St 1 and St 2, Kst < 200 to 300

- Acceptable temperature range: ambient -30 to +50 °C, process up to +120°C at max +50°C ambient

- Max air velocity through diverter: 25 m/s

- Pressure loss approx.: 400 Pa at 17 m/s, 500 Pa at 20 m/s

- Max vacuum: -250 mbar

- Materials: hot dip galvanized body, 1.4571/AISI 316Ti lid, silicone gasket

WANT MORE TECHNICAL DETAILS? DOWNLOAD OUR DATASHEET.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

Thorwesten Vent – Type STT SL – Explosion Diverter

- Designed for vacuum conveyor processes

- Admissible explosion propagation lengths are operation-specific

- Vent area ranges: 0.5 m² to 1.52 m²

- Admissible reduced explosion pressure: max 2.4 barg

- Dust explosion classes: St 1 and St 2

- Admissible temperatures: ambient -40 to +50 °C, process up to +120 °C

- Max. explosion overpressure: ≤9 bar

- Body and lid of diverter: hot-galvanized

- Materials vary by temperature application: structural steel S235JR or stainless steel 1.4571

- Compressed air connection: 6 bar / G ¼ female thread

WANT MORE TECHNICAL DETAILS? DOWNLOAD OUR DATASHEET.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

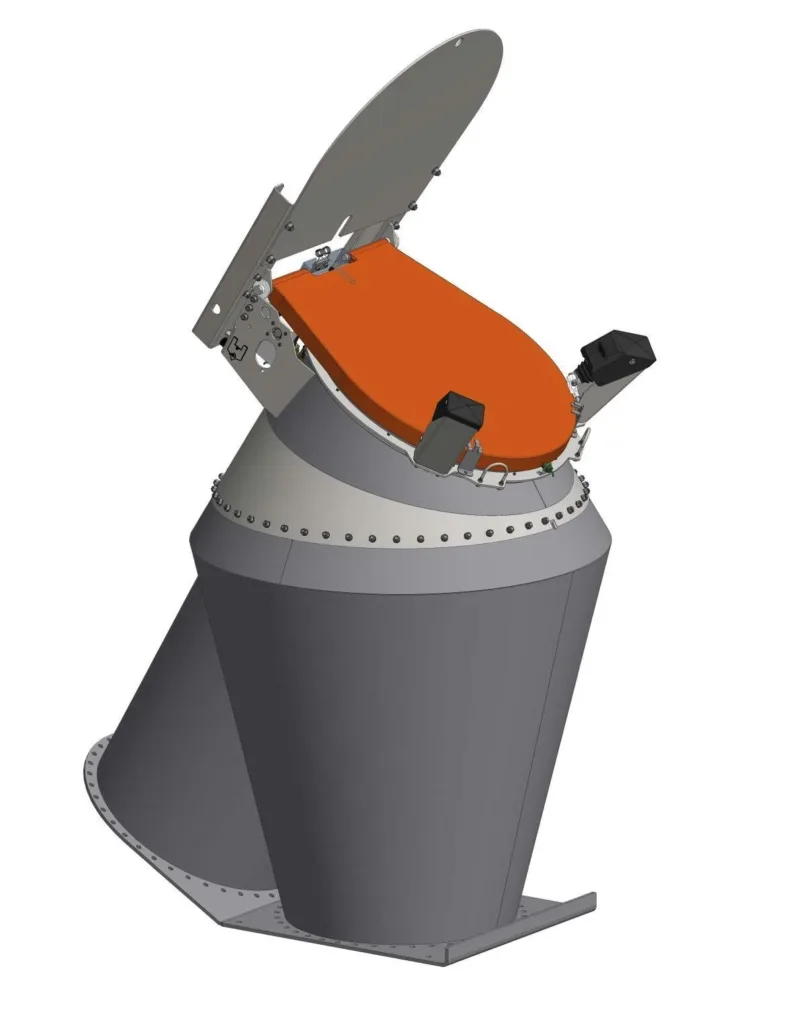

Thorwesten Vent – Type STT G2 – Explosion Diverter

- Designed specifically for duct relief with vacuum conveying conditions.

- Max permissible pressure-wave run-up speeds vary: 80 m/s to 270 m/s.

- Lid weights range from 12.3 kg to 67.3 kg.

- Effective vent areas span from 0.27 m² to 1.76 m².

- Maximum reduced explosion pressure Pred max at 3.0 bar.

- Dust explosion classifications cater to both St 1 (Kst < 0…200) and St 2 (Kst < 200…300).

- Admissible ambient temperature range: -30°C to +50°C, with process temperatures up to +115°C.

- Adaptable to different system and characteristic values via expert evaluation.

- Features a static response pressure stat at 0.02 bar.

- Material construction includes hot dip galvanized explosion door body and stainless steel for process-exposed lid aspects.

- Recoil forces vary significantly based on Pred, indicating the system’s adaptability to varying operational pressures.

WANT MORE TECHNICAL DETAILS? DOWNLOAD OUR DATASHEET.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!