Celebrating 25 Years 1999-2024

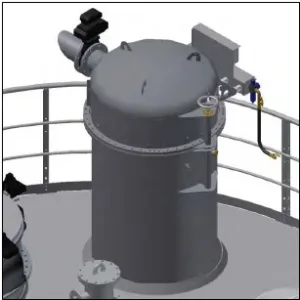

Thorwesten Vent – 2 Barg Pressure Shock Resistant, Maintenance Friendly Dust Collectors For Silo De-dusting

Thorwesten Vent’s constructional explosion protection product profile now includes pressure shock resistant dust collectors for de-dusting applications in silos.

Advantages Of The Design

- Designed to de-dust or filter the air displaced in silos

- Simplifies explosion protection of silos because the filter now becomes an integral part of the constructional explosion protection design of the complete silo by having an equal or better pressure shock resistance than the silo.

- All the components of the filter that can be exposed to the explosion pressure in case of a dust explosion in the silo are designed to withstand the pressure shock

- reduces explosion protection complexity and costs

- No additional maintenance platform needed, if the filter is directly mounted on the silo roof

- Explosion vents can be placed on silo only – no additional explosion vent needed on the filter , due to the 2 barg pressure shock resistance

- No additional explosion diverter (decoupling) needed at filter inlet, or other optional explosion isolation equipment between filter and silo due to the 2 barg pressure shock resistance.

- In cases where silos are located indoors – then explosion suppression or flameless venting of silos (eg food industry) is made easy.

- Maintenance friendly – Easy maintenance by swiveling the head to the side without need for removing the electric (cable trays, etc.)

- Filter bags made of electrically, non conducting fabric and are cleaned automatically by compressed air jets.

- Optional with or without 2 barg pressure shock resistant fan directly mounted on the clean air.

If correctly fitted, connected and earthed, commissioned, operated and maintained in accordance with the manufacturer’s instructions, the filter construction complies with the conditions for use in zone 20 inside and zone 22 outside (control unit) in accordance with 1999/92/EC. The filter is not considered under the interpretation of a “safety system” and once the pressure shock resistance has been demonstrated it requires no further approval ( e.g. type-examination certificate). The documented evidence of the pressure shock resistance can be obtained from TV/CMC upon request. The pressure shock resistance must correspond to the pressure shock resistance of the silo on which the filter is directly mounted and of which it thus becomes a component.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!