Celebrating 26 Years 1999-2025

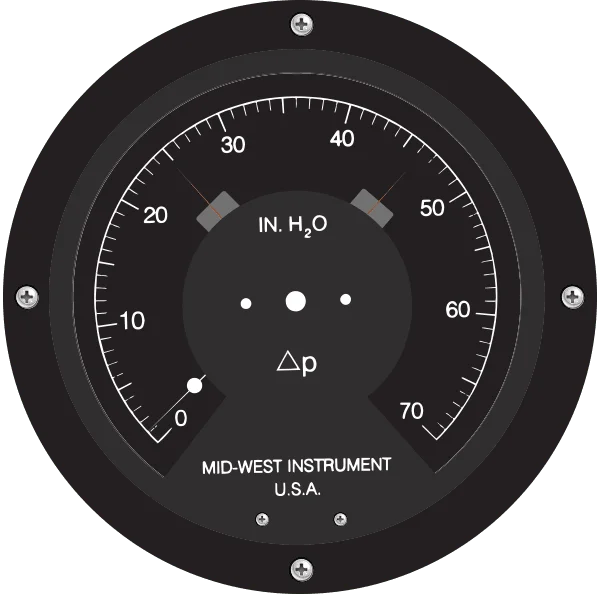

Mid-West Instrument Bourdon Tube Type Differential Pressure Gauge

Bourdon Tube Gauges are very precise with a ± 1/2% or ± 1% Full Scale Accuracy. The pressure straightens the tube which were arc shaped before and that makes a curve trace and the change in pressure reflects on gauge dial face.

Mid-West Bourdon Tube Differential Pressure Gauge Working Principle

The Mid-West Bourdon Tube assembly is encapsulated in a high pressure chamber that is fitted with a pressure connection to the inside of the Bourdon Tube and a second connection to the pressure chamber.

The pressure chamber for the assembly is small, close fitting and rugged. The volume displacement of the Bourdon Tube through the pressure range is near to zero (0.02 c.c.). The speed of response of the indicator to changes in differential pressure is instantaneous, even on low volume pressure systems. The low volume displacement is an important advantage for differential pressure leak detection, and when isolation diaphragms are required.

The Bourdon Tube Assembly is protected against over-range in either direction to the rated working pressure by a bi-directional relief valve. The output shaft of the gauge assembly is magnetically coupled through the solid wall of the pressure chamber to a sensitive jewelled pointer shaft in the dial housing outside the chamber. The magnetic coupling transmits the exact motion of the assembly to the pointer to give an accurate dial reading of the differential pressure.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

Note: The use of diaphragm seals is not recommended for Model 109 series gauge. Attempts to install such seals on these gauges will void the warranty.

Mid-West Model 109 Bourdon Tube Differential Pressure Gauge

Mid-West Model 109 is powered by a test quality Bourdon Tube Assembly. The Model 109 indicates the difference between the pressure applied inside the Bourdon Tube and the pressure inside the chamber.

- Wide DP Range from 0-15 PSID to

0-6000 PSID - Bourdon Tube Sensing Element

- Working Pressures up to 6000 PSIG (400 bar)

- Over-Range Protection, High over Low and Low over High

- Gauge Housings Available in Aluminum, Brass, Carbon Steel and 316/316L Stainless Steel

- Wide Range of Elastomers

- Over-range Protection – Full to Maximum Working Pressure

- Panel Mounting – Standard, Front or Panel 6″ or 4-1/2″

- Pipe Mounting Kit – Optional, 2″ U-Bolt

- Wall Mounting – Optional – Flush Panel or Rear Bracket

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!