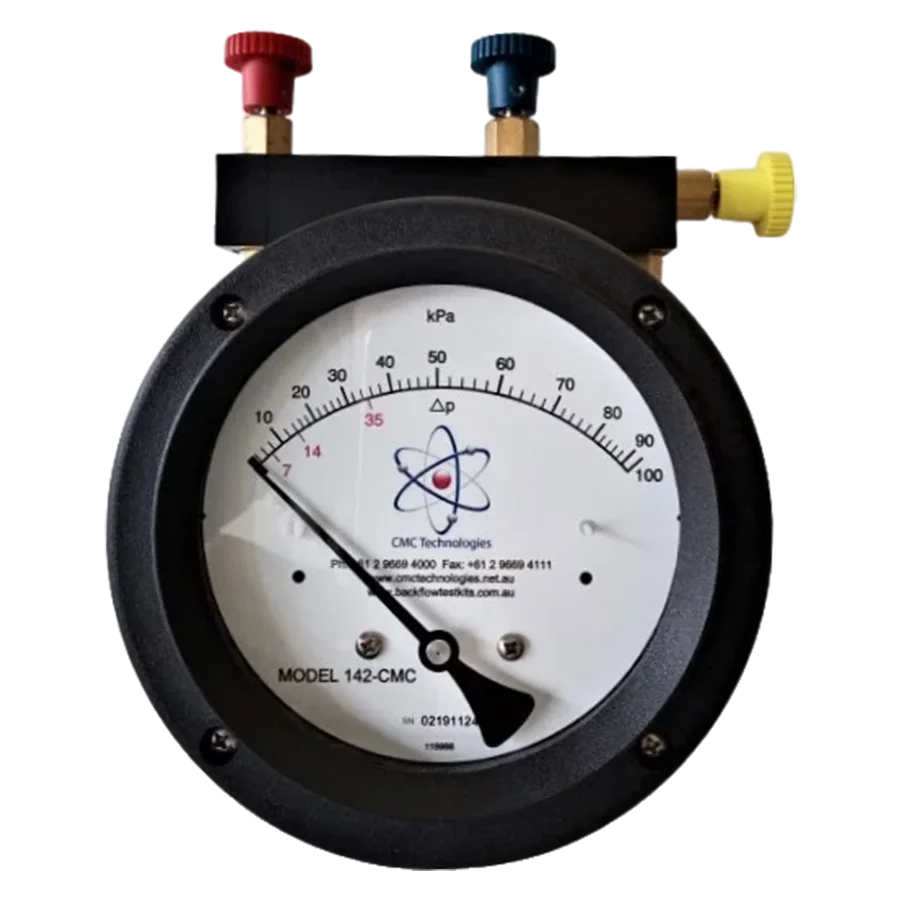

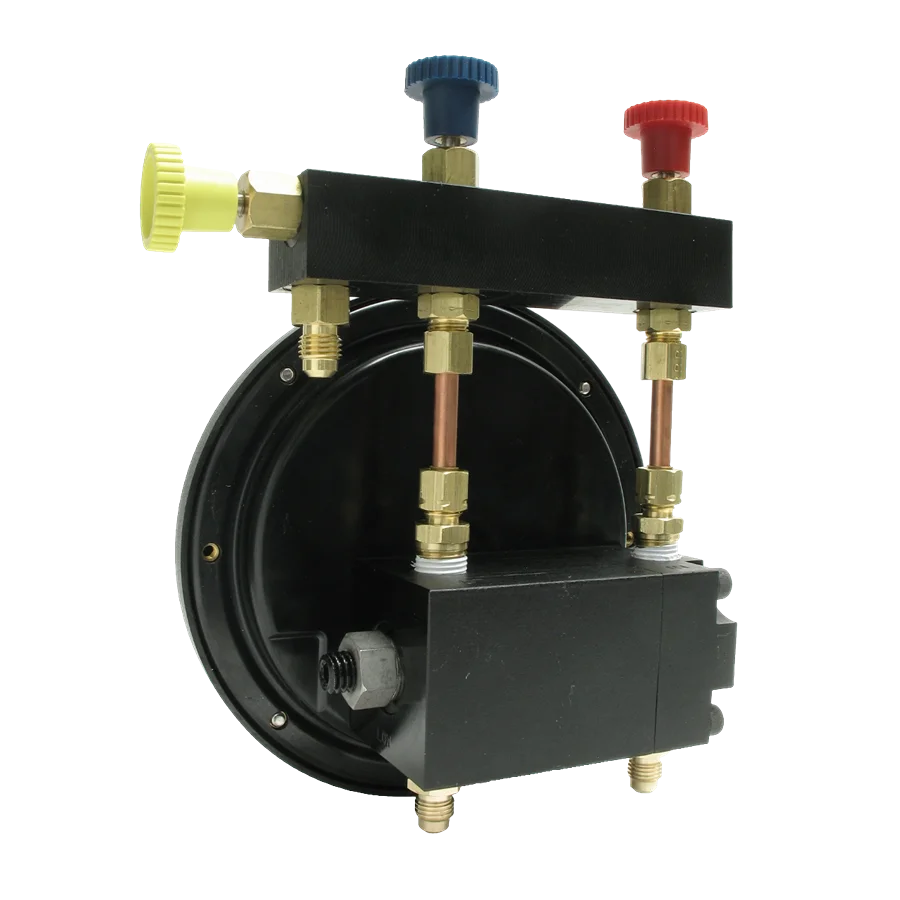

Model 855 Digital Backflow Test Kit & Machbackflow App

- 5 Valve Digital Backflow Test Kit

- Precision digital technology for accurate backflow testing

- Automated data logging and intuitive digital interfaces

- Instant comprehensive reporting with digital signatures

- Durable, proven materials for daily use

- Tests RP, PVB, and DC backflow assemblies

- ΔP Range: 0-15 PSID, Pressure sensor 0-200 PSIG

- Reads ΔP and line pressure on phone, saves results to cloud

- App works with Wi-Fi, Cellular, Offline; filters and searches tests

- Premium features: autofill, .csv downloads, PDF generation (30-day trial)

- Seamless Bluetooth integration with iOS/Android Machbackflow app

- Consistent with Model 845 components for familiarity

- Durable molded plastic case with organized storage

- 90-micron filters for debris minimization, easy to clean/replace filters

- Includes: hoses, bleed tube, brass fittings, cell phone holder

- Long-term reliability with 5-year warranty

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!