Celebrating 26 Years 1999-2025

Level Measurement

Flow Monitoring Alarm Applications

Flow monitoring devices are used for Pump protection, Cooling Water flow, Analytical Sample Confirmation, Safety Shower Monitor, Heat transfer fluid monitor, Rotating Equipment Lubrication, Safety Relief valve Monitor, Bursting Disc or Rupture Disk Sensor, Flow Confirmation, Oven Exhaust / Air Purge Monitor, Dry line Indication, Soot Blower Feed Water monitor, Chemical Injection Monitor, Vapour Recovery Monitor, Fire Suppression System Monitor, Gas Purge Confirmation, and Sanitary Cleaning System monitor.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

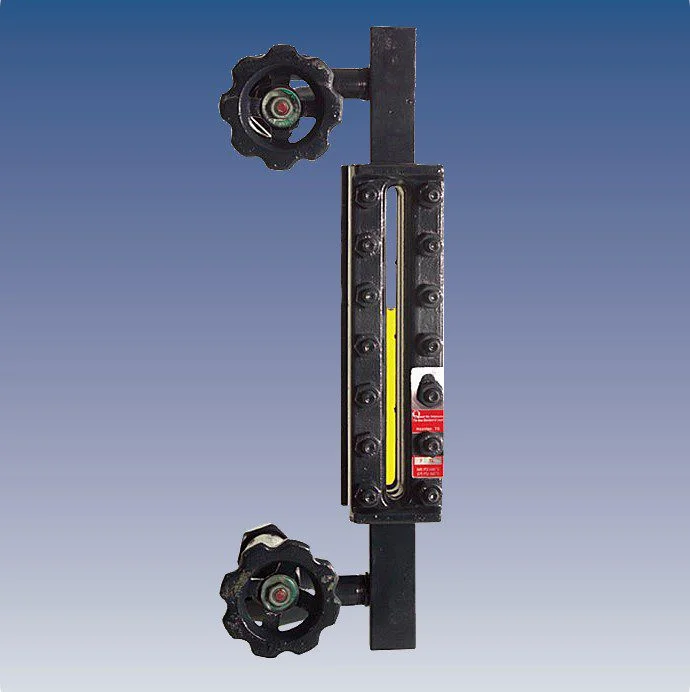

Level Indication Applications

Level monitoring devices are essential for applications such as Tank Leak Detection, Tank Overflow Monitoring, Truck and Railcar Loading, Reactor Charging, Foam Control, Water Detection in Fuel Tanks, Sump Level Monitoring, Stream Trap Level Control, Interface Detection, Immersion Heater Protection, and as a Backup for Continuous Level Monitoring. These devices, including magnetic and armored level gauges, provide accurate and reliable readings to enhance safety and operational efficiency in various industrial settings.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

Available Level Measuring Technologies

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!