Celebrating 27 Years 1999-2026

Level Sensors

High Level Alarm Fluid Level Monitoring Sensor UZK-A

The UZK-A model Uzka Fluid Level Sensor is specifically designed for reliable fluid level detection in remote or mobile tanks. This battery-operated device is IECEx-certified, making it suitable for use in hazardous areas. It features both audible and visual alarms to alert users once the liquid reaches the sensor, and it includes two magnetic floating sensors capable of monitoring up to 2 liquid levels. The device is compatible with gasoline, diesel oil, and similar mediums.

Specifications

- Power Source: 4xAAA LR03 1.5V NANFU batteries.

- Alarm Types: Audible and visual alarms.

- Ambient Temperature Range: -40℃ to 60℃.

- Alarm Volume: ≥110 dB.

- Ex-mark: II1 G Ex ia IIB T4 Ga.

- Certified Approvals: IECEx, ATEX.

- IECEx Certification Number: Presafe 18.0084X.

- ATEX Certification Number: Presafe 18 ATEX 13423X.

Common Applications

- Ideal for monitoring fluid levels in mobile or remote tanks used in various industrial settings.

- Suitable for hazardous environments requiring IECEx-certified equipment.

- Provides reliable level detection in gasoline and diesel storage applications.

- Used in environments where audible and visual alerts are crucial for safety compliance.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

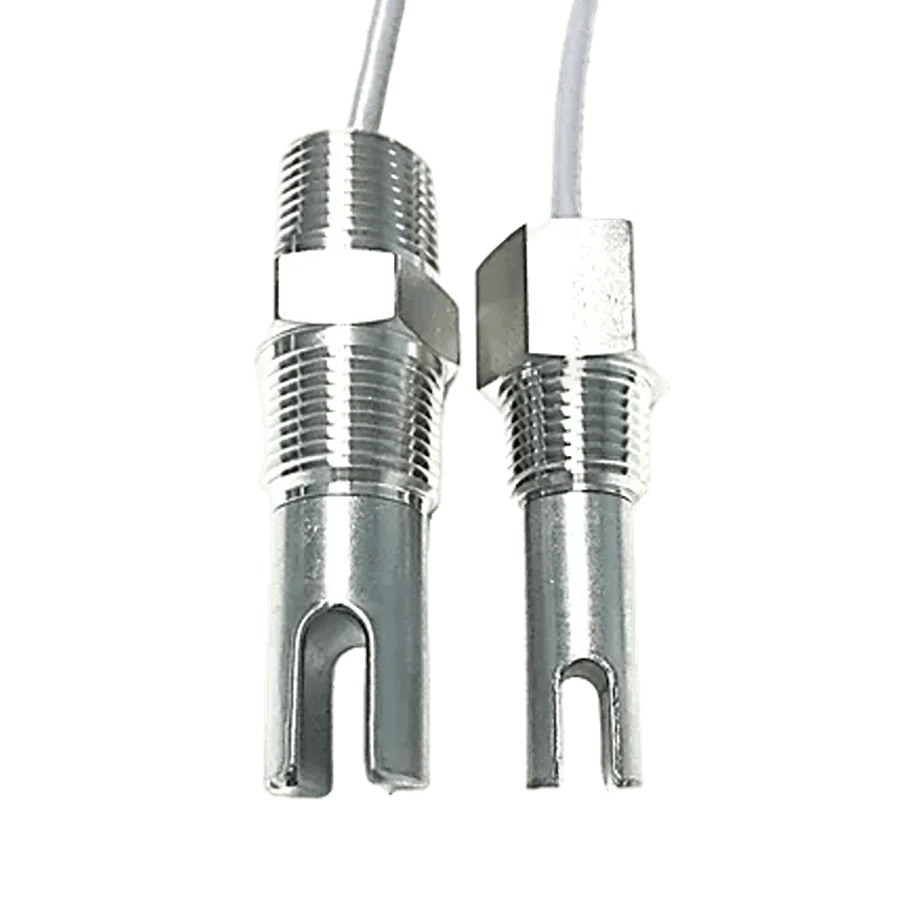

Tuning Fork Level Switch UZK- Y

The UZK-Y model Tuning Fork Level Switch is a highly reliable control switch used specifically for liquid level detection. This switch is very compact in design with the forks size at only 40mm making this flow meter most suitable for level detection in pipes. With delicate fork adaptable to the density as low as 0.5g/cm³, this flow meter have been used widely in many industrial applications.

Specifications

- Capable of detecting liquid densities larger than 0.5g/cm³.

- Operable across a broad viscosity range from 0.1 to 10000 mPa.s.

- Can handle liquid flow rates of up to 6m/s.

- The probe operates at a frequency of 1000Hz.

- Requires 20-250V AC/20-72V DC input, with low power consumption. The output is relay-type, incorporating a double-pole double-throw (DPDT) relay with a PNP signal.

- Engineered to withstand process pressure ranges from -1 to 100 bar, and temperature ranges from -50 to +300°C in the process environment, and -40 to +70°C in the ambient environment.

- Offers an IP66/IP67/IP68 protection class, with options for explosion-proof certifications as well.

Common Applications

- Ideal for monitoring the level of liquids in chemical processing plants such as reactors or storage tanks where precise measurement is crucial.

- Utilized in the oil storage and transportation sectors for reliable level detection, preventing overfills.

- Ensures consistent level measurement in food and beverage sector piping systems in environments with strict hygiene requirements.

- Provides accurate level detection in pharmaceutical process vessels under varying pressure and temperature conditions.

- Employed in water treatment facilities to monitor the level of fluids within containment systems and process pipelines.

WANT MORE TECHNICAL DETAILS? DOWNLOAD OUR DATASHEET.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

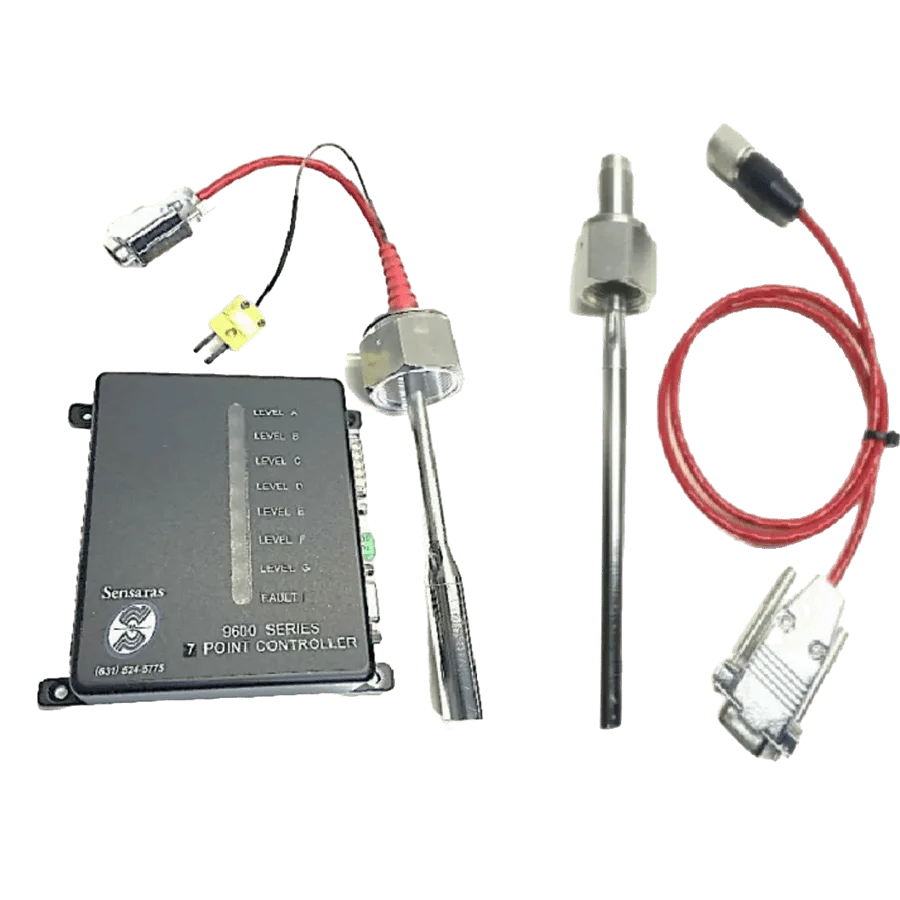

Sensaras PLS 960 Series Multi-Point Level Monitoring Ultrasonic Point Level System

The PLS 960 Series Ultrasonic Point Level System is engineered for precise detection of ultra-pure liquid chemical levels in bubblers and ampoules used in the semiconductor industry, specifically in PVD, CVD, and ALD processes. Designed to fit ½” or ¾” VCR fill ports, this system features probes with no moving parts, eliminating contamination risks. The sensor’s performance is unaffected by chemical colour, dielectric constant, density, or viscosity. Customisable with multiple sensing points, the probe is made from 316L stainless steel with an electro-polished finish and undergoes leak testing for reliability. Electronics are remotely mounted to accommodate high-temperature environments, requiring no calibration or adjustment between sensors.

Specifications

- Probe Length: Customisable to any length.

- Thermocouple Option: K-Type thermocouple sensor available.

- Set Point Spacing: Minimum 0.1” (2.5 mm) apart.

- Lowest Sensing Point: 0.3” (7.6 mm) from canister bottom; 0.2” (5 mm) from sensor end.

- Point Capacity: Up to 7 points on ¾” VCR; up to 5 points on ½” VCR.

- Temperature Range: Standard up to 120°C; special high-temp up to 180°C.

- Electronics Output: LED indicator and 1A SPDT relay per point.

- Fault Detection: Includes 1A SPDT fault function relay.

- Optional Features: Fail-safe relay contacts; Watch-Dog-Timer circuit; TC display with fail-safe.

Common Applications

- Monitoring ultra-pure liquid chemical levels in semiconductor process bubblers and ampoules.

- Suitable for PVD, CVD, and ALD semiconductor manufacturing environments.

- Ideal for applications requiring contamination-free, reliable level detection without moving parts.

- Used where chemical properties like colour, viscosity, and density vary without affecting sensor accuracy.

- Applicable in high-temperature settings up to 180°C with remote electronics for safety.

- Customised solutions tailored to specific canister dimensions and process requirements.

WANT MORE TECHNICAL DETAILS? DOWNLOAD OUR DATASHEET.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

Sensaras CLS 860 Series Continuous Level Monitoring Ultrasonic Point Level System

The CLS 860 Series Ultrasonic Point Level System provides continuous detection of ultra-pure liquid chemical levels in bubblers and ampoules used in the semiconductor industry, including PVD, CVD, and ALD processes. Designed to fit ¾” VCR fill ports or non-invasively through Sensaras-designed canister sides, it accurately senses the liquid interface height from the bottom. With no moving parts, the probe prevents contamination and is unaffected by chemical colour, dielectric, density, or viscosity. Custom-made to user specifications, the invasive probe is constructed from 316L stainless steel with an electro-polished finish and leak tested for reliability. Electronics are remotely mounted to support high-temperature applications. Calibration or adjustment between sensors or liquids is not required.

Specifications

- Output Signal: Analog output options – 4-20mA or 0-5V over desired measurement range.

- Set Points: Four NPN output set points with LED display upon level detection.

- Temperature Measurement: Analog output provided for temperature monitoring.

- Communication: RS-232 standard; optional Bluetooth display available.

- Probe Construction: Single sensor made from 316L stainless steel.

- Dual System: No calibration needed for liquid changes or temperature compensation.

- Customisation: Probes tailored to user specifications and canister design.

- Mounting: Fits ¾” VCR fill port or non-invasive side mounting on Sensaras canisters.

Common Applications

- Continuous monitoring of ultra-pure liquid chemical levels in semiconductor bubblers and ampoules.

- Ideal for PVD, CVD, and ALD process environments requiring precise interface height detection.

- Suitable for chemical applications where contamination risk must be minimised with no moving parts.

- Effective where chemical properties such as colour, viscosity, and density vary without affecting accuracy.

- Used in environments demanding remote electronics for high-temperature operation.

- Custom solutions designed to fit specific canister configurations and customer requirements.

WANT MORE TECHNICAL DETAILS? DOWNLOAD OUR DATASHEET.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

Sensaras PLS 262 Series High Gain Dual Level Ultrasonic Point Level System

The PLS-262 Series Ultrasonic Point Level System is designed for reliable dual-point liquid level control in storage vessels and tanks. Featuring integrated electronics, this system is suitable for a wide range of liquid level applications. The probe is made from durable 316L stainless steel, while the electronic module is housed in a plastic cassette enclosed within a NEMA 4/7 explosion-proof housing. No calibration is required, simplifying installation and maintenance. An LED indicator provides visual system status, and a field-selectable fail-safe relay supports auto fill or empty control. The system includes a demand push-button self-test for operational assurance and incorporates a 0.5 second delay from wet to dry signals to prevent false alarms caused by wave action.

Specifications

- Probe Material: 316L stainless steel construction.

- Electronics: Integrated electronic module in explosion-proof NEMA 4/7 housing.

- Relay Control: Auto Fill or Empty relay with field-selectable fail-safe.

- Visual Indicator: LED status display on electronic module.

- Self-Test: Demand push-button for system function verification.

- Response Delay: 0.5 second delay to avoid false trips from wave action.

- Lengths Available: Up to 60” probe length.

- Calibration: None required for installation or maintenance.

Common Applications

- Dual-level liquid monitoring and control in storage tanks and vessels.

- Suitable for various liquids regardless of colour, viscosity, dielectric constant, or density.

- Ideal for hazardous environments needing explosion-proof equipment.

- Used where reliable auto fill or empty control is necessary.

- Applications demanding minimal maintenance and no calibration.

- Environments where wave action could cause false alarms without delay features.

WANT MORE TECHNICAL DETAILS? DOWNLOAD OUR DATASHEET.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

Sensaras PLS 160 Series Low Cost Ultrasonic Point Level System

The PLS 160 Series Ultrasonic Point Level System offers a cost-effective solution for liquid detection in compact spaces. With integrated electronics, it serves as a direct replacement for float switches, capacitance, and optical detectors. This versatile system is widely used for high-level overflow alarms, low-level pump protection, condensate pots, sump water and oil detection, lubricant circulation equipment, fill machine level control, and pump leak detection. This low-cost system combines reliability and versatility, making it an ideal choice for various industrial liquid level monitoring needs.

Specifications

- Electronics: Integrated electronic module.

- Probe Material: 316L stainless steel construction.

- Lengths Available: Up to 60” probe length.

- Optional Materials: Variety of engineered plastics available for enhanced corrosion resistance.

- Calibration: No calibration or periodic maintenance required.

Common Applications

- High-level overflow alarm systems in tanks and vessels.

- Low-level pump protection to prevent dry running.

- Detection of condensate in pots and sump water monitoring.

- Oil detection in water or lubricant circulation systems.

- Level control in filling machines and leak detection in pumps.

- Suitable for use in compact spaces requiring reliable liquid detection.

- Applications needing corrosion-resistant sensor options for process vessels.

WANT MORE TECHNICAL DETAILS? DOWNLOAD OUR DATASHEET.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

Sensaras PLS 161 Series Low Level Ultrasonic Point Level System

The PLS 161 Series Ultrasonic Point Level System is designed for low-level liquid detection in storage vessels, tanks, and pipes. Featuring integrated electronics, it supports both AC and DC inputs with options for a 10A SPDT relay or loop-powered 4-20mA output, making it suitable for nearly any liquid level monitoring application. The probe is constructed from 316L stainless steel, and the electronic module is housed in a plastic cassette within a NEMA 4/7 explosion-proof enclosure. No calibration is required, simplifying installation and maintenance. An LED indicator provides visual system status, while field-selectable fail-safe relays offer flexible operation. Continuous self-diagnostics check probe connections, and a demand push-button self-test confirms system functionality. A 0.5 second delay from wet to dry prevents false trips caused by wave action.

Specifications

- Probe Material: 316L stainless steel construction.

- Electronics: Integrated electronic module in explosion-proof NEMA 4/7 housing.

- Power Inputs: Supports AC and DC power.

- Output Options: 10A SPDT relay or loop-powered 4-20mA analog output.

- Visual Indicator: LED status display on electronic module.

- Self-Diagnostics: Continuous probe connection checks and demand push-button self-test.

- Fail-Safe: Field-selectable relay energisation on power-up or normal condition.

- Response Delay: 0.5 second delay to avoid false alarms due to wave action.

- Lengths Available: Up to 60” probe length.

- Calibration: None required for installation or maintenance.

Common Applications

- Low-level liquid detection in storage tanks, vessels, and pipelines.

- Suitable for hazardous environments requiring explosion-proof equipment.

- Ideal for applications needing reliable self-diagnostics and fail-safe operation.

- Used in industries where liquids vary in colour, viscosity, dielectric constant, or density.

- Applications demanding minimal maintenance and no calibration.

- Environments where wave action may cause false alarms without delay features.

WANT MORE TECHNICAL DETAILS? DOWNLOAD OUR DATASHEET.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

Sensaras PLS 162 Series High Gain Level Ultrasonic Point Level System

The PLS 162 Series Ultrasonic Point Level System is designed for high-level liquid detection in storage vessels and tanks, including applications involving aerated or viscous liquids. Featuring integrated electronics, it supports both AC and DC power inputs with options for a 10A SPDT relay or loop-powered 4-20mA output. This versatile system suits nearly any liquid level monitoring need. The probe is constructed from 316L stainless steel, and the electronic module is housed within a plastic cassette inside a NEMA 4/7 explosion-proof enclosure. No calibration is necessary, ensuring easy installation and minimal maintenance. An LED indicator provides clear visual status, while field-selectable fail-safe relays allow flexible operation. Continuous self-diagnostics monitor probe connections, and a demand push-button self-test confirms system functionality. A 0.5 second delay from wet to dry prevents false alarms caused by wave action.

Specifications

- Probe Material: 316L stainless steel construction.

- Electronics: Integrated module in explosion-proof NEMA 4/7 housing.

- Power Input: Supports AC and DC power sources.

- Output Options: 10A SPDT relay or loop-powered 4-20mA analog output.

- Visual Indicator: LED status display on electronic module.

- Self-Diagnostics: Continuous probe connection checks with demand push-button self-test.

- Fail-Safe Operation: Field-selectable relay energisation on power-up or normal condition.

- Response Delay: 0.5 second delay to avoid false trips due to wave action.

- Lengths Available: Up to 60” probe length.

- Calibration: Not required for installation or maintenance.

Common Applications

- High-level liquid detection in storage tanks and vessels.

- Suitable for aerated or viscous liquids where standard sensors may struggle.

- Ideal for hazardous environments needing explosion-proof equipment.

- Used in industries where liquids vary in colour, viscosity, dielectric constant, or density.

- Applications requiring reliable self-diagnostic features and fail-safe operation.

- Environments where wave action could cause false alarms without delay.

WANT MORE TECHNICAL DETAILS? DOWNLOAD OUR DATASHEET.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

Sensaras PLS 163 Series Sludge Blanket Ultrasonic Point Level System

The PLS 163 Series Ultrasonic Point Level System is designed for accurate detection of sludge levels in clarifiers and tanks. It automates pump or valve operation to maintain sludge at the desired level, enhancing plant efficiency and effluent quality. By enabling automatic sludge withdrawal for controlled time periods, the system ensures sludge of the right density is delivered to digesters or thickeners, while preventing solids carryover into the effluent system. The PLS 163 system’s ultrasonic technology eliminates moving parts, ensuring reliable operation unaffected by colour, viscosity, dielectric constant, or density variations.

Specifications

- Probe Material: Rugged 316L stainless steel construction.

- Electronics: Integrated electronic module housed in a plastic cassette within NEMA 4/7 explosion-proof enclosure.

- Visual Indicator: LED status display on electronic module for easy monitoring.

- Fail-Safe Operation: Field-selectable relay energisation on power-up or normal condition to de-energise when liquid is present.

- Self-Test: Demand push-button feature for system function verification.

- Sensor Flexibility: Usable as a single point sensor or multiple sensors for detecting sludge at various levels.

- Calibration: Not required, simplifying maintenance.

Common Applications

- Monitoring sludge blanket levels in clarifiers and tanks.

- Automatic control of pumps and valves for sludge withdrawal.

- Enhancing wastewater treatment plant efficiency and effluent quality.

- Preventing solids carryover into effluent systems.

- Suitable for environments requiring explosion-proof equipment.

- Applications where sludge density control is critical for process optimisation.

WANT MORE TECHNICAL DETAILS? DOWNLOAD OUR DATASHEET.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

Sensaras PLS 164 Series Low Temperature Ultrasonic Point Level System

The PLS 164 Series Ultrasonic Point Level System is specifically designed to detect liquid levels in low-temperature environments ranging from -50°C to 120°C. Suitable for storage vessels, tanks, and pipes, this system fits almost any liquid level application. The probe is constructed from durable 316L stainless steel, while the electronic module is housed in a plastic cassette within a NEMA 4/7 explosion-proof enclosure. An LED indicator provides clear visual system status. Field-selectable fail-safe relays allow energising on power-up or normal conditions, de-energising when liquid is present. The demand push-button self-test feature assures reliable system operation. The PLS 164 offers reliable ultrasonic technology with no moving parts, ensuring consistent performance under challenging low-temperature conditions.

Specifications

- Temperature Range: -50°C to 120°C.

- Probe Material: 316L stainless steel construction.

- Electronics: Integrated module in explosion-proof NEMA 4/7 housing.

- Visual Indicator: LED status display on electronic module.

- Fail-Safe: Field-selectable relay energisation on power-up or normal condition.

- Self-Test: Demand push-button for system function verification.

- Lengths Available: Up to 60” probe length.

- Calibration: Not required for installation or maintenance.

Common Applications

- Low-temperature liquid level detection in storage tanks, vessels, and pipelines.

- Suitable for industrial processes involving cryogenic or chilled liquids.

- Ideal for hazardous environments requiring explosion-proof equipment.

- Used where reliable, maintenance-free level detection is essential.

- Applications where varying liquid colour, viscosity, dielectric constant, or density are factors.

- Environments demanding robust sensors able to operate at sub-zero temperatures.

WANT MORE TECHNICAL DETAILS? DOWNLOAD OUR DATASHEET.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

Sensaras PLS 166 Series Solar Powered Ultrasonic Point Level System

The PLS 166 Series Ultrasonic Point Level System is designed for liquid level detection in storage vessels, tanks, and pipes where power supply is limited or unavailable. Powered by solar energy, this system offers a reliable solution for remote or off-grid applications. The probe is constructed from durable 316L stainless steel. The electronic module, solar power system, and accessories are housed in a powder-coated die-cast aluminium enclosure for robust protection. No calibration is required. A LED strobe indicator provides clear visual status, complemented by an audio alarm and reset switch. Battery status monitoring and a demand push-button self-test ensure proper operation. A 0.5 second delay from wet to dry prevents false alarms caused by wave action. The PLS 166 combines solar power with ultrasonic technology ensuring no moving parts and consistent performance regardless of liquid properties.

Specifications

- Probe Material: 316L stainless steel construction.

- Power: Solar-powered system with low current draw (1–3mA).

- Enclosure: Powder-coated die-cast aluminium housing.

- Visual Indicator: LED strobe status indicator on enclosure.

- Audible Alarm: Standard audio alarm with reset switch.

- Self-Test: Demand push-button for system function verification.

- Response Delay: 0.5 second delay to avoid false trips due to wave action.

- Calibration: None required for installation or maintenance.

Common Applications

- Liquid level detection in remote or off-grid storage tanks and vessels.

- Ideal for locations where traditional power supply is unavailable or costly.

- Suitable for industrial and environmental monitoring requiring solar power.

- Applications needing reliable alarm systems with visual and audio alerts.

- Used in settings where varying liquid colour, viscosity, dielectric constant, or density exist.

- Environments requiring maintenance-free, durable level detection technology.

WANT MORE TECHNICAL DETAILS? DOWNLOAD OUR DATASHEET.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

Sensaras PLS 167 Series Interface Level Ultrasonic Point Level System

The PLS 167 Series Ultrasonic Point Level System is designed for detecting the interface level between two non-homogenous liquids or between solids suspended in liquid. Its robust probe is made from 316L stainless steel, while the electronic module is housed within a plastic cassette mounted inside a NEMA 4/7 explosion-proof enclosure. The system features an LED indicator to clearly display status. Field-selectable fail-safe relays allow energising on power-up or normal conditions, de-energising when liquid is present. A demand push-button self-test ensures the system is functioning correctly, providing dependable performance in challenging environments. The PLS 167 employs ultrasonic technology with no moving parts, ensuring consistent and accurate detection regardless of liquid or solid characteristics.

Specifications

- Probe Material: 316L stainless steel construction.

- Electronics: Electronic module captured in plastic cassette housed in NEMA 4/7 explosion-proof enclosure.

- Visual Indicator: LED status indicator on electronic module.

- Fail-Safe Operation: Field-selectable relay energisation on power-up or normal condition.

- Self-Test: Demand push-button for system function verification.

- Calibration: Not required, simplifying maintenance.

Common Applications

- Detection of interface levels between two non-mixing liquids.

- Monitoring solids suspended within liquids in tanks or vessels.

- Suitable for hazardous environments requiring explosion-proof equipment.

- Ideal for industrial processes where precise interface level control is critical.

- Applications where liquid properties such as colour, viscosity, dielectric constant, or density vary.

- Environments demanding reliable, low-maintenance level monitoring solutions.

WANT MORE TECHNICAL DETAILS? DOWNLOAD OUR DATASHEET.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

Sensaras PLS 168 Series Non-Invasive Ultrasonic Point Level System

The PLS-168 Series Ultrasonic Point Level System is designed for non-invasive detection of liquid presence or absence within tubes using ultrasonic technology. It transmits and receives sound waves without penetrating the tube, ensuring contamination-free operation. The sensor can be fitted with process connections for easy installation and eliminates the need for customer adjustments. Miniaturised electronics are integrated into the sensor. Custom-built to fit tubes ranging from 6.3 mm to 19 mm in diameter, it detects bubbles or air-in-line accurately. Sensors for larger tube sizes are available upon consultation. Each sensor is tailored to specific tube size, flow rate, and user input/output requirements, requiring no calibration. The PLS 168 utilises ultrasonic technology with no moving parts, providing reliable detection unaffected by liquid colour, viscosity, dielectric constant, or density.

Specifications

- Electronics: Integrated miniaturised electronics built into the sensor.

- Tube Material: Mounted on 316L stainless steel tubing.

- Tube Size Range: Designed for tubes 6.3 mm to 19 mm diameter; larger sizes available on request.

- Installation: Optional process fittings for easy and secure mounting.

- Calibration: Not required due to custom sensor design.

- Construction: 316LSS tubing with or without fittings.

Common Applications

- Non-invasive detection of liquid presence or absence in process tubes.

- Monitoring for bubbles or air-in-line in liquid flow systems.

- Suitable for applications where contamination must be avoided.

- Ideal for precise flow monitoring in medical, semiconductor, or chemical industries.

- Used where maintenance-free operation and no calibration are essential.

- Detection systems requiring adaptation to specific tube sizes and flow conditions.

WANT MORE TECHNICAL DETAILS? DOWNLOAD OUR DATASHEET.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!