Celebrating 26 Years 1999-2025

Primary Flow Signal (PFS) – Orifice Plates & Flanged Unions

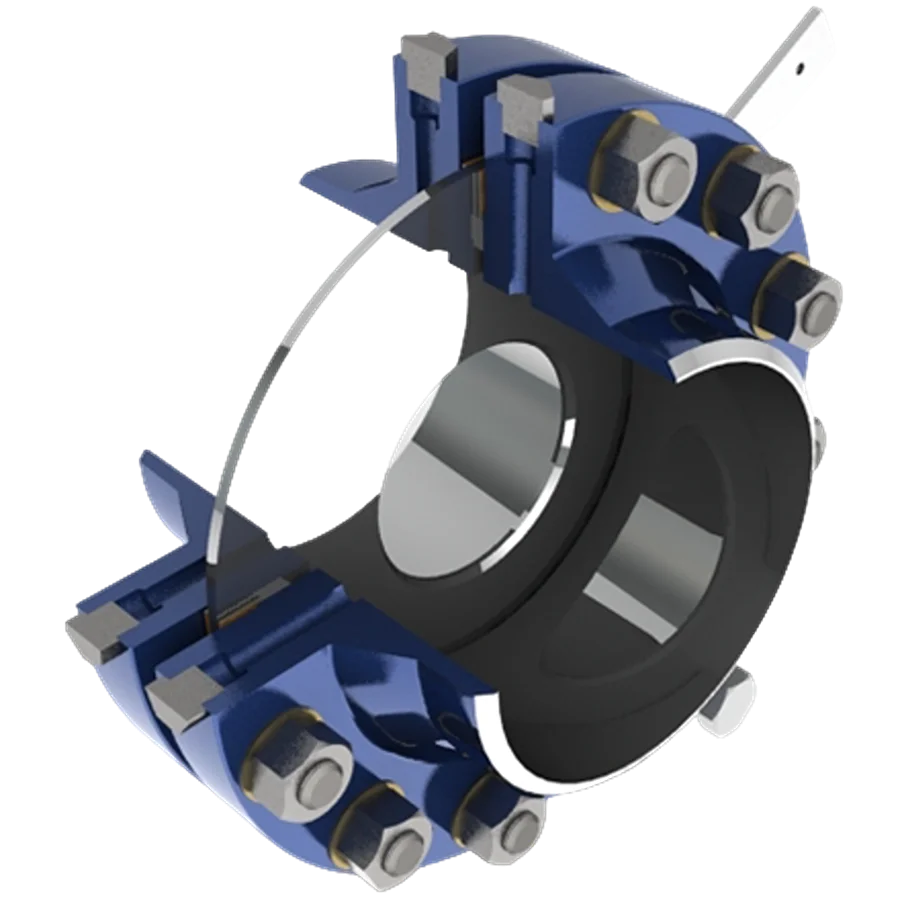

The PFS Orifice plates, or orifice primary flow elements, flange unions, and holding blocks offer lower capital investment and ease of replacement. The technologies are field-proven and well suited for a variety of applications.

Orifice Plates & Flanged Unions

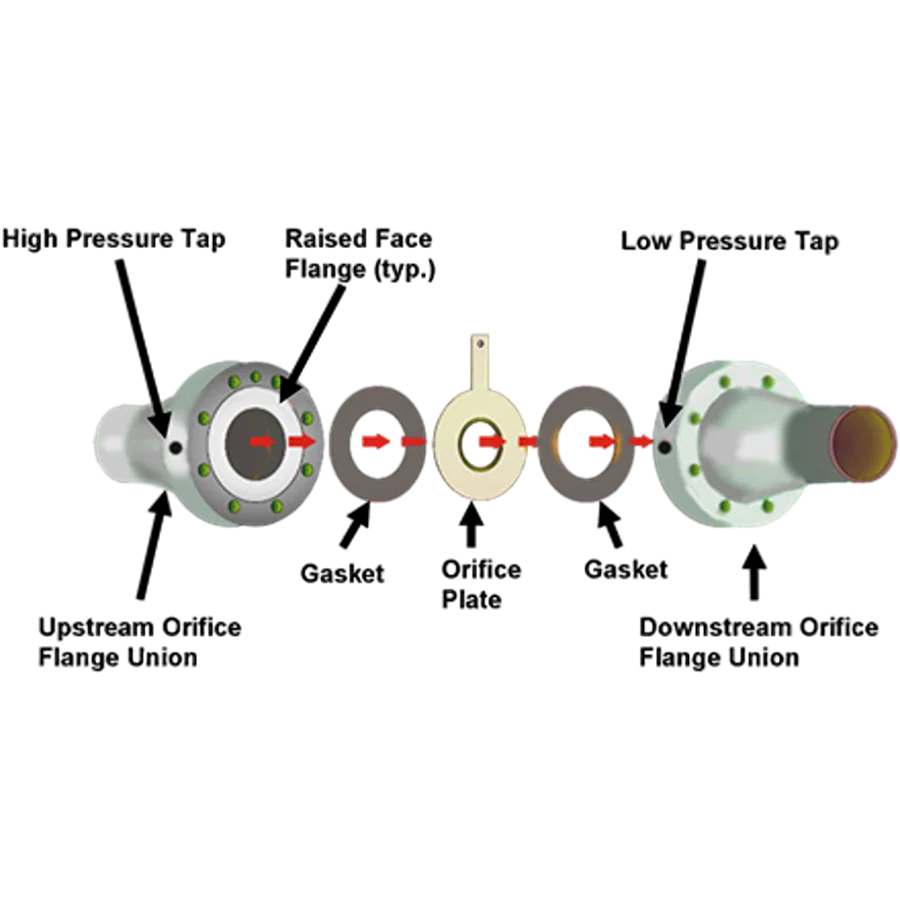

The PFS-OP orifice plate in line sizes from ½” and above is one of the most common differential producer type flow elements for the measurement of clean liquids, gasses and low-velocity vapour (steam) flow. Of the many design varieties described in technical manuals, codes and standards, the most prevalent configuration in the United States of America is the square-edged concentric paddle type orifice plate in combination with flange tapped carriers.

This design offers the optimum flexibility for applications with many diverse existing piping schemes as well as considerable economies available in terms of capital investment associated with the initial purchase of equipment.

The design provides the means for relatively easy replacement of the orifice plate when necessitated b changes in the nominal flow rates in a given application installation or as might be required due to deterioration of accuracy performance of the installation. The operation of the flow element is based upon the Bernoulli principle and relies upon the comparison of the pressure upstream and downstream (differential pressure) of the constriction represented by the orifice plate bore to infer the rate of flow of the line fluid through the bore diameter.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

Application And material Construction

Applications: The PFS-OP is designed to measure full pipe, clean gasses or liquids over extreme temperature or low velocity vapour or steam. Typical applications include potable water, high pressure steam, combustion air, compressor surge control, oxygen & nitrogen measurement for air separation plants, petrochemical and chemical plants process measurement and control (alcohol, ethylene, chlorine, etc.)

Material of Construction: Typical material selections for standard application orifice plates are 304 or 316 stainless steel. Other options for material selection are Monel, Hastelloy, Titanium and brass. All equipment is available cleaned for oxygen service if required. All plates are stamped with identification data including material grade, bore size, line size, flange rating and tag number.

Design and Manufacturing Standards:

- All materials are mill certified and of first quality

- All applicable codes and standards are considered such as A.G.A, the I.S.A., the A.N.S.I., and A.P.I. recommendations.

- Each orifice plate is manufactured with strict adherence to ISO 9001 certification standards thereby applying numerous inspections at key points in the production process assuring the squareness and sharpness of the bore edge remains well within the tolerances permitted by the above referenced codes and standards.

PFS Orifice Model Numbers:

- PFS-OP Orifice Plate

- PFS-OFU Orifice, Union, Flanged

- PFS-OFU Orifice, Union, Flanged, Run

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

Benefits And Advantages of Orifice Plates

The orifice plate is one of the most common differential producer type flow elements for measuring clean liquids, gases, and low-velocity vapor (steam) flow. The design offers optimum flexibility ideal for applications with many diverse existing piping schemes, and require considerably lower investment for the initial purchase of equipment. The orifice plate also has the advantage of relatively easy and low-cost replacement.

Unlike other differential pressure flow elements such as venture type meters where the line fluid upstream and downstream of the constriction are generally and variously conditioned the energy consumed by the line fluid flowing through the orifice metering section is considerably higher.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!