Celebrating 27 Years 1999-2026

Lumiglas Sight Glass Accessories

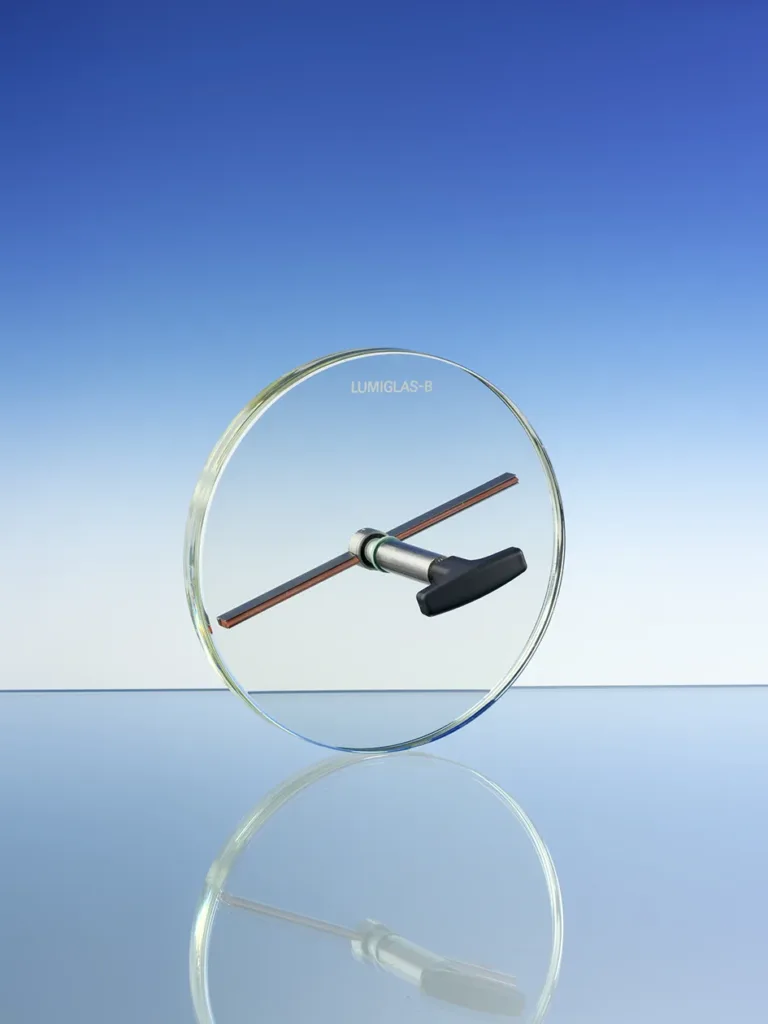

Lumiglas Sight Glass Wiper SW I

The Lumiglas Sight Glass Wiper SW I is used to clean circular sight ports with a diameter of up to 400mm (16″inches). The wiper is used for site glass fittings like DIN 28120/28121 or similar. The wiper operates manually using a hand wheel, a pneumatic version is also available. The central bore is designed to fit nominal sizes DN 50 (2″) to DN 400 (16″). The Lumiglas wiper SW I is designed to perform reliably under the harshest working conditions. It provides great flexibility, is easy to service and virtually maintenance free. The SW I is vacuum tight and pressure resistant up to 6 bar depending on the diameter of the glass/luminaire. It can be used at temperatures of up to 220°C (428°F), however you should check the glass temperature rating fitted is capable of withstanding the temperature required in operation. The wiper can be used in a hazardous area without any difficulty. Sight glass wipers (models SW I and SW II) may be used either alone to clean a sight port or in combination with a flow indicator, spray device or Lumistar luminaries.

Specifications

- Fits circular sight glass assemblies per DIN 28120 from DN 50 to DN 400.

- Installs into a sight glass disc with a 10.5 mm central hole according to DIN 7080/8902.

- Vacuum tight and pressure tight up to 6 bar, varying with glass diameter.

- Able to operate in environments with temperatures as high as 220°C, depending on the glass material chosen.

- Various components including polycarbonate, stainless steel, and options for bushings in brass or PEEK.

- Available with ratchet-drive lever and also compatible with Lumistar luminaires for enhanced lighting in the operational area.

- Certified by the state material testing authority of Nordrhein-Westfalen, Dortmund.

Common Applications

- Can be used where regular cleaning of sight glasses is necessary to monitor process integrity in chemical processing equipment.

- Providing manual wiping capabilities for tanks in hygienic applications in food and beverage tanks where visibility is critical.

- Ensuring clear observation of processes in environments such as biotech and pharmaceutical vessels where cleanliness is paramount.

- Supporting regular maintenance of sight glasses exposed to high temperatures and pressures in petroleum and refining units.

- Assisting in the visibility of operations in waste water treatment plants within tanks and pipes that may accumulate residue over time.

WANT MORE TECHNICAL DETAILS? DOWNLOAD OUR DATASHEET.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

Lumiglas Sight Glass Wiper SW II (Ex Zones Applicable)

The Lumiglas® sight glass wiper SW II is a sturdy cleaning system for circular sight glass discs conforming to DIN 28120 or similar. It has been designed to clean sight glass inside surfaces that are not in direct line of sight. It is undoubtedly the ideal solution in high-pressure and vacuum conditions. The unit is most suitable for nominal sizes DN 100 to DN 200. The wiper can used in Ex-Zone 0, 1, 2 and non-hazardous areas. The sight glass wiper is pressure and vacuum resistant. Its capable of operating temperatures up to 220°C and glass can be supplied for up to 16 Bar pressure tolerance.

Specifications

- Utilizes pressure-tight glands for secure attachment through base and cover flange of sight glass assembly.

- Wiper blades available in PTFE or silicone rubber, with all product-contact parts made of stainless steel; drive internal seal made of PTFE.

- Vacuum tight and up to 16 bar pressure; maximum temperature capacity of 220°C (dependent on glass disc type).

- Can be fitted with Lumistar luminaires or a spray device simultaneously for added functionality.

- Accompanied by test certificates from Nordrhein Westfalen’s state material testing authority.

Common Applications

- Ideal for manual cleaning of sight glasses on reaction vessels across various industries, operating under vacuum or pressure.

- Enables visual inspection maintenance in pharmaceutical vessels, where clean and clear sightports are essential.

- Suitable for the hygienic demands of the food and beverage industry’s sight glass equipped containers.

- Applicable in chemical plants needing regular interior glass cleaning to ensure process visibility.

- Supports inspection clarity in the petrochemical sector where pressure resistance and material compatibility are critical.

WANT MORE TECHNICAL DETAILS? DOWNLOAD OUR DATASHEET.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

Lumiglas Spray Device (Ex Zones Applicable)

Lumiglas Spray Device is manufactured to fit to any circular sight glass according to DIN 28120. It is an a well designed accessory for cleaning of sight port glasses or ports on pressure and vacuum vessels. They are ideal for either intermittent or continuous cleaning to suit your requirement. The Spray Device can be used in Ex hazardous and non-hazardous areas and is suitable for use with all sight glass fittings according to the pressure equipment directive and DIN 28120. Using a Spray-Device together with other Lumiglas accessories like the Lumiglas Luminaire and Wiper for keeping the sight glass free from any contamination that would hinder perfect viewing considering the operational temperature and glass disc temperature resistance.

Specifications

- Features pressure-tight screwed gland nozzles for straightforward installation through the sight glass assembly flanges.

- The operating conditions of the spray device correspond to the sight glass fitting rating.

- Utilizes PTFE for seals with all metallic contact parts made from high-grade stainless steel 1.4571.

- Includes a spray jet head, locknut, two seals, a connecting nozzle of 10 mm OD x 1.5 mm bore with hexagon shank, along with detailed fitting instructions.

- When part of a complete sight glass assembly, the device is pre-drilled and tapped to match Lumiglas specifications, potentially requiring a non-return valve depending on the operation setup.

Common Applications

- Regularly cleans sight glasses on chemical process vessels where observation is hindered by deposits or reactions.

- Ensures continuous clear visibility in pharmaceutical reactors for monitoring critical processes.

- Provides necessary sight port glass cleaning in food and beverage tank systems, maintaining hygiene.

- Automates the cleaning of sight glasses in biotech fermenters, mitigating the need for manual maintenance.

- Keeps sight glass windows clear in the oil and gas industry’s pressurized containers, improving safety checks.

WANT MORE TECHNICAL DETAILS? DOWNLOAD OUR DATASHEET.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!