Explosion Suppression

Explosion Suppression Technologies

The amazing developments are said to have occurred in the field of active explosion protection systems used in process plants over the past 70 years. System design methodology: Improved system design methodologies have brought the introduction of more comprehensive design tools that take into account numerous hazard variables for optimised explosion protection. Detection technologies: The incorporation of dynamic detectors and data capture memory buffers into detection technologies has seen explosion detection systems become more robust, resulting in a reduction in the number of false alarms. Electromechanical explosion suppressors: Significant improvements have been made in the performance of electromechanical explosion suppressors with better functionality, testing capability, and diagnostics. Control unit technologies include multi-zone protection, self-testing, digital display, improved communication, and thus easier monitoring and diagnostics.

Explosion Suppression Systems

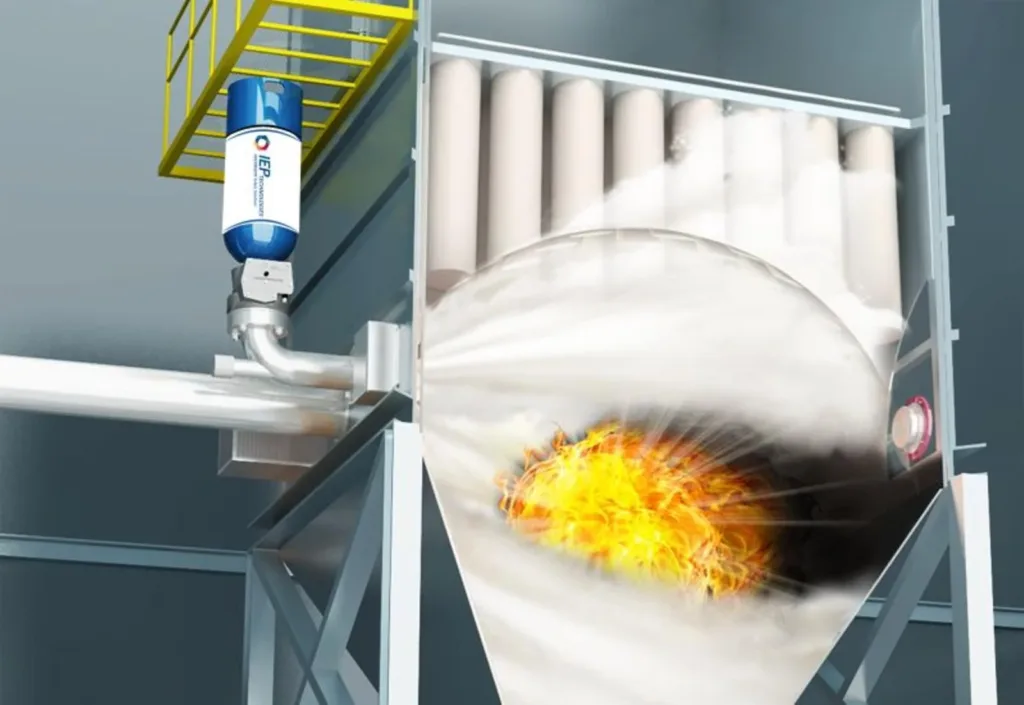

Explosion suppression relies on early detection, and the rapid deployment of a suitable suppressant to extinguish the incipient explosion. The correct system design ensures that the resultant reduced explosion pressure, PRED, is below the plant pressure shock resistance. Explosion propagation upstream and downstream would usually be mitigated as part of the system design by incorporating extinguishing barriers or in combination with explosion isolation valves.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

Whether the best explosion protection solution has suppression, venting, isolation, or a hybrid combination, CMC Technologies provides the right products to meet your needs. Our system components undergo rigorous third-party testing to receive the approvals required by, for example, ATEX and NFPA. As each explosion protection threat is unique, we offer different types of explosion detectors, controls, and suppressors to tailor the protection to each individual application.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

IEP Technologies

IEP Technologies acquired the explosion protection business of the world-leading brands Kidde, Fenwal, and Incom in 2013. IEP Technologies in 2015 became part of the Hoerbiger Safety Solutions Group. CMC Technologies exclusively represents IEP Technologies in Australia and New Zealand.

Whether the best explosion protection solution is suppression, venting or isolation, IEP Technologies offers the right products to meet your needs. Our system components undergo rigorous third-party testing to receive the approvals required by, for example, ATEX and NFPA. As each explosion protection threat is unique, we offer different types of explosion detectors, controls and suppressors to tailor the protection to each individual application.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

Explosion Prevention and Suppression System Components

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!