Celebrating 25 Years 1999-2024

Explosion Prevention & Protection

For Dust Explosions and Gas Explosions

Dust and/or gas explosions occur often in industrial processes where combustible material is transported/pneumatically or mechanically conveyed, heated, filtered, spray-dried, milled, and stored. A deflagration (an explosion that travels at less than the speed of sound) can be initiated by an ignition source within a confined space with the right concentration of dispersed dust and oxygen, resulting in a pressure shock, overpressure, and a flame ball/fireball.

If an uncontrolled deflagration is allowed to run in ductwork or pipes it can transition to a detonation (an explosion traveling at a speed greater than the speed of sound) – or transfer with very high energy to adjoining enclosures causing devastating damage.

CMC Technologies provides a complete range of explosion prevention and protection equipment. This includes explosion venting, explosion suppression and isolation, flame protection – deflagration and detonation flame arresters, smouldering fire and post-explosion fire protection, static earthing clamps and systems, spark detection and extinguishing, emergency inerting, explosibility testing, and pressure shock resistant silos for fuels grinding systems.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

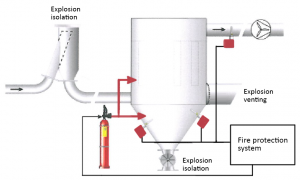

Explosion Venting

Explosion venting is a cost-effective method used for industrial explosion protection solutions when the fireball and overpressure from an explosion can be released effectively and safely into the environment.

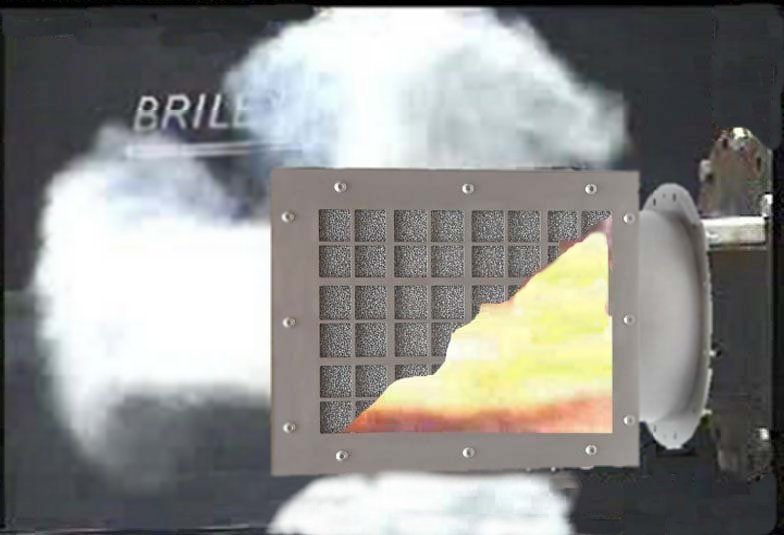

To prevent damage or rupture of a vessel the explosion vent, at a predetermined, certified set pressure (Pstat), releases the products of rapid combustion in a controlled manner, preventing widespread damage to plant and personnel. The correct effective area is calculated in accordance with EN14491:2012 or NFPA 68:2023 for isolated enclosures and then installed in accordance with these standards. Brilex explosion vents (now owned by IEP Technologies – Hoerbiger Safety Solutions) are reliable and cost-effective. Acquired by IEP Technologies, the brand has been further enhanced with the new releases of the IV* flameless explosion vents and the Hoerbiger EVN 3.0 Flameless, automatically reclosing explosion relief valve. CMC Technologies also distributes the Thorwesten Vent’s air-cushioned automatically reclosing explosion doors that can be reused after several explosions.

Explosion vents should be used in combination with explosion isolation equipment. Vent area design calculations in accordance with EN14491:2012 are valid when explosion vents are used in isolated enclosures. In particular, explosions that initiate in one vented vessel shall be prevented from propagating to connected vented vessels. This is because the calculation methods are not valid for flame jet ignition cases. In some cases, explosion isolation measures are not needed and these specific cases are defined in EN14491:2012. As well, after the vented release of an explosion, post-explosion fires may occur, unless an explosion door that recloses and combined with gas extinguishing or inserting is used. A post-explosion fire as a result of explosion venting needs to be considered in the risk assessment and further measures should be considered.

- Brilex Explosion Vents

- Type GE Domed Explosion Vent

- Type KE Flat Explosion Vent

- Type KER Flat Explosion Vent with Reinforced Edges

- Thorwesten Vent Explosion Doors

- Explosion Vent Area Calculations – Sizing

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

Explosion Suppression

CMC Technologies can assist to determine is the best explosion protection solution for your application. It may be explosion suppression, explosion venting, or explosion isolation, or a combination of both. Together with our Partner IEP Technologies, we can offer the right products to meet your needs.

IEP Technologies’ system components undergo rigorous third-party testing to receive the approvals required by, for example, ATEX and NFPA. We offer different types of explosion detectors, controls, and suppressors to tailor the protection to each individual application as each explosion protection threat is unique.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

Explosion Isolation

Secondary explosions tend to cause the most damage in an unprotected system, rather than the first explosion if there are insufficient explosion isolation measures. Often vessels are only protected with explosion venting, and while this may relieve some overpressure, there is still a risk of further damage.

The process and plant areas can be further protected by the use of explosion isolation products in combination with explosion vents , whether they are flameless devices or simple bursting discs with vent ducting.

- Active Explosion Isolation

- IEP Technologies Isolation Valves & System Components

- Rico Active Isolation Valves

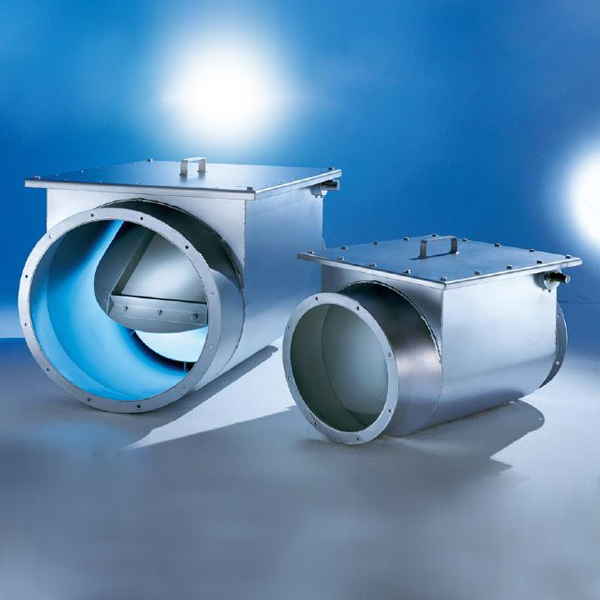

- Passive Explosion Isolation

- Brilex Passive Explosion Isolation Valves & Explosion Diverter

- IEP Technologies Passive Explosion Isolation Valve

- Rico Ventex Passive Isolation Valves

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

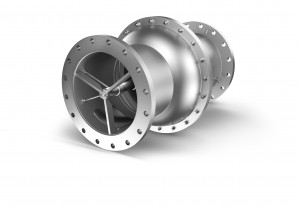

Flame Protection

KITO Armaturen specialises in the design, specification and manufacture of deflagration and detonation flame arresters. These flame arresters are passive explosion protection devices with no moving parts, designed to offer reliable protection in areas where flammable gas is being transported, or a flammable liquid is being stored.

KITO Flame arresters are available for inline and end of line applications , deflagration and detonation types as well as endurance burn proof flame arresters.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

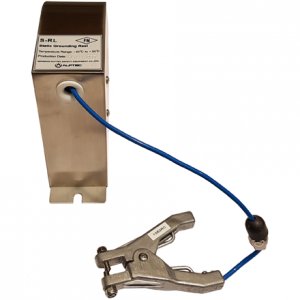

Static Earthing

Static electricity is an ever-present and significant hazard for operations taking place in flammable, combustible or potentially explosive atmospheres.

The uncontrolled build up and discharge of electrostatic must be avoided in these environments in order to prevent ignition to protect people, plant, processes and the environment. CMC Technologies via its representations with ATC and Alptec provides a range of static earthing solutions to create a safer workspace. Please contact us for more information regarding our static earthing clamps and systems.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

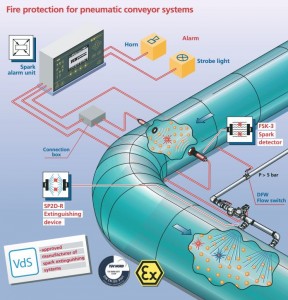

Spark Detection & Extinguishing

T&B Electronic spark extinguishing systems are designed and manufactured in Germany and have been VdS-approved since 1984, preventing Fires and explosions is important in many industries where powders and dusts are handled.

Based on T and B’s VdS-approved fire protection system , T and B design customized protection concepts for the protection of filters, silos, processing machines, pneumatic suction systems and many more production applications. CMC Technologies distributes T and B Spark extinguishing systems in exclusively in Australia and New Zealand.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

Smouldering Fire Protection – CO Monitoring – Early Warning

Carbon Monoide (CO) is produced as a main intermediate gas at an early stage of a smouldering nest – typically formed in milk powder spray driers. The ability to detect CO at an early stage allows for early action to prevent a fire or explosion in the spray drier.

CO systems have been on the market for more than 15 years. CMC Technologies has now a modern system that was developed by robecco GmbH in Germany that has improved on many features that have limited the performance and reliability of CO systems to date.

The robecco CO system is the only truly continuous system on the market.

- robecco Smouldering Fire Protection – CO Monitoring – Early Detection

- Dairy Industry

- Pulverised Fuels

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

Explosibility Testing

CMC Technologies collaborates with IEP’s Combustion Research Center to provide explosibility testing for combustible dusts in Australia and New Zealand. They conduct a variety of tests to deliver reliable data for developing robust safety measures in handling combustible process materials.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

Emergency Inerting

CMC Technologies, in partnership with Yara Industrial, provides tailor-made Emergency Inerting Systems to inhibit fires and explosions by reducing oxygen levels with inert gases. Used worldwide across various industries, these systems are designed to meet unique safety requirements.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

Post-Explosion Fire Protection

CMC Technologies offers IEP Technologies’ Post-Explosion Fire Protection solutions, designed to prevent post-explosion fires, particularly in vented installations. With an array of fire suppressants and temperature sensors for early fire detection and automatic extinguishing, they provide robust safety management.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

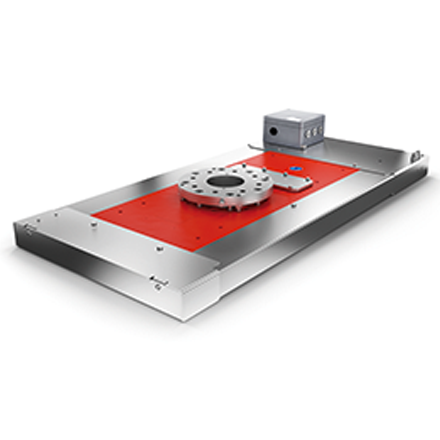

Silos for Pulverised Fuels – Pressure Shock Resistant

CMC Technologies, in partnership with Thorwesten Vent, offers pressure shock resistant silos and dust collectors. These solutions are perfect for storing ground or secondary fuels and for de-dusting applications in silos. With an array of designs, including pressure shock resistant silo roofs and hulls, these systems ensure maximum safety and efficiency in your industrial operations.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!