Celebrating 27 Years 1999-2026

Active explosion isolation systems (as opposed to passive isolation devices) comprise explosion detection by using dynamic pressure and/or infrared flame detection, a control panel that takes the signal and processes it and then instantaneously activates in the pipeline either a powder suppressor, fast acting quick slide valves, certified ball valves or other types of isolation valve(s).

Chemical isolation uses an explosion suppressant (powder usually sodium bicarbonate special mix) discharged into the ductwork, (eg between interconnected vessels) to extinguish the propagating flame front before it has the opportunity to travel and achieve an enhanced explosion or flame jet ignition to a connected vessel.

Mechanical isolation involves triggering a high-speed valve to form a mechanical barrier in the pipeline. This barrier can protect against flame as well as pressure propagation into connected vessels.

IEP Technologies Active System Schematic & Components

Whether the best explosion protection solution is suppression, venting, or isolation, IEP Technologies offers the right products to meet your needs. Our system components undergo rigorous third-party testing to receive the approvals required by, for example, ATEX and NFPA.

As each explosion protection threat is unique, we offer different types of explosion detectors, controls, and suppressors to tailor the protection to each individual application.

An explosion suppression system is designed to detect and stop explosions in industrial equipment within milliseconds. It includes three main parts: pressure detectors, a control unit, and suppression devices.

When an ignition occurs, pressure sensors instantly detect the rapid pressure rise and signal the control unit. The system then releases suppressant at high speed into the vessel, cooling and extinguishing the fireball before it can fully develop.

Most systems also include explosion isolation to prevent flames or pressure from spreading to connected equipment, improving overall plant safety.

IEP Technologies – Control Unit

A control unit is microprocessor-based and has both control and verification functions. It is comprised of control and battery charging circuits, a power supply, and a front panel which includes control and indication functions visible through a scratch-resistant window. A unit is packaged in an enclosure to provide superior dust contamination and weather resistance. Terminal access has been carefully designed for ease of installation.

Any signals emerging from the explosion pressure or flame sensors are recorded, tested, and evaluated by the control unit. The monitoring and activation lines are continuously checked for wire breakage, earth fault, and short circuit. Additionally, an automatic self-test system ensures that all important functions of the control unit are checked electronically. These control units provide both trouble relay contacts for process interlocking, and alarm relay contacts for notification should a system actuation occur.

- Single-Zone – EX-100.1, EX-200

- Multi-Zone – EX-8000

NEED MORE TECHNICAL DETAIL? DOWNLOAD OUR DATASHEET.

IEP Technologies – MEX Detector and FAB Unit

Dynamic measuring cells in the detector sense changes in pressure. Once pre-programmed pressure values have been exceeded the detector reacts within microseconds to raise an alarm. The MEX Detector has up to two ceramic sensors within a single, solid housing. This is the only detector with algorithmic-based output and decision-making logic based on full-scale explosion tests, expert knowledge, and application experience.

The output and decision logic provide the highest detection security by evaluating the difference between an explosion pressure rise and process pressure variations. The ceramic cell sensors make the detector more resistant to mechanical damage and corrosive dust, gases, and liquids. By means of a field terminal box (“FAB”), the MEX Detector can be connected to various control units.

- Dynamic pressure detection is based on the characteristic temporal profile of pressure increase associated with confined explosion occurrences. This significantly increases false alarm immunity as well as detection security.

- Comprises two pressure-sensing cells to increase detection security and redundancy.

- Field-programmable unit to accommodate a wide range of hazard and process conditions. Also features a history buffer for programming set point during commissioning as well as diagnosis of incidents after actuation.

WANT MORE TECHNICAL DETAILS? DOWNLOAD OUR DATASHEET.

IEP Technologies – Infrared and Ultraviolet Infrared Detectors

Optical detectors include infrared (“IR”) and ultraviolet infrared (“UV-IR”) detectors which are integrated into explosion protection systems for specific applications. The IR detector is typically used in interconnected duct work for dust-handling systems. The UV-IR detector is used in combustible gas or vapor protection systems such as aerosol fill rooms and chemical storage rooms.

- IR-13 Infrared Flame and Spark Detector

- UV/IR Flame Detector

WANT MORE TECHNICAL DETAILS? DOWNLOAD OUR DATASHEET.

IEP Technologies – Static Explosion Pressure Detector

The IEP Technologies Static Explosion Pressure Detector is a low inertia detector incorporating a highly sensitive stainless steel diaphragm. The diaphragm is mounted onto a 6-inch diameter eight (8) hole nickel-plated steel mounting flange. The flange is bolted to a cast aluminum housing protected by epoxy paint. The screw cover to the housing has an o-ring seal to protect the field adjustable switch assembly housed within.

As standard, the pressure detector comes with a 24-inch long braided cable assembly. A standoff mounting kit is also available. The mounting kit consists of a stainless steel standoff pipe, a detector mounting bracket, a hose assembly, hose clamps, gaskets, and an adaptor plate.

IEP Technologies Chemical/Powder Isolation

IEP Technologies – Protractor Operated HRD (PHRD) Chemical/Powder Suppressor

IEP explosion isolation suppressors are used for explosion suppression of gases, solvent vapours, and combustible dust. The suppressors deliver high rates of suppressant that quench an explosion flame in its early stages, thus preventing a pressure rise from reaching dangerous proportions

A cylindrical alloy steel container filled with 3kg, 4kg,16kg, or 35 kg of powder suppressant and pressurised to 60 bar (880 psi) with dry nitrogen. Inside the flange is a hinged flap supported by a beam which is kept closed by a latch. Two pistons, non-explosive protractor-operated actuators are used to initiate the opening. When the actuators are activated by means of an electrical impulse from the associated control unit, pistons move the latch, which allows the flap to open and provide a clean, unrestricted opening. The nitrogen then expels the suppressant at a high rate through the spreader assembly into the protected volume.

WANT MORE TECHNICAL DETAILS? DOWNLOAD OUR DATASHEET.

IEP Technologies Chemical Isolation

IEP Technologies – High Speed Sistag Isolation Valve

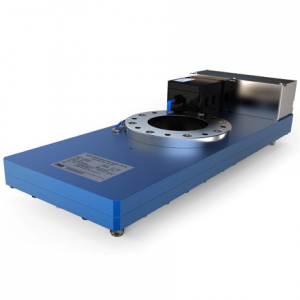

Guard your workplace with the HSI Series Knife Gate Valve from Wey Valve. Designed explicitly for use in pipelines at risk of dust explosions, the HSI Valve acts as a bulwark to prevent explosions from spreading beyond its installation point. With an astounding closing time of just 23 milliseconds, this valve stands as a beacon of industrial safety, securing not only your systems but most notably, human lives at work.

- The HSI Series covers a wide range of nominal sizes from 65 to 400mm.

- Crafted from durable stainless steel (1.4408), this valve is built to withstand demanding environments.

- Offers a pressure rating of 0 to 16 bar, with flange drilling provisioned for PN16, ANSI Class 150, and DIN 11864-2.

- Can be customized to specific face-to-face dimensions (“special length”)

- Does not use gas generators or pyrotechnics.

- Can be used for several explosion isolation applications.

- Minimised downtime.

- Very fast resetting.

The valve’s construction also has considerations for facilities requiring heightened hygiene. Those parts include the body and gate, both of which are made from hygienic 1.4408 stainless steel, while the seal uses PTFE or FDA-approved PTFE/Silicone. The stem/piston rod is made from lightweight, yet robust, aluminium.

WANT MORE TECHNICAL DETAILS? DOWNLOAD OUR DATASHEET.

Rico Active Isolation Valves

The RICO Slide Valve RSV provides reliable protection from explosions in a pipeline system. Available in different versions, these valves are suitable for use both in pharmaceutical media and for systems that process dust and gas.

Rico’s VENTEX ESI are explosion isolation systems after EN15089:2009D. Explosion isolation with VENTEX valves is used in systems in which combustible dusts, gases or hybrid mixes are processed.

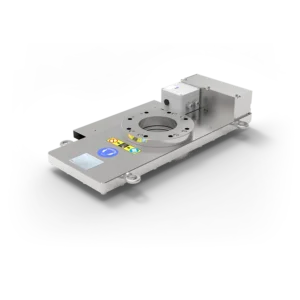

Rico – Slide Valves RSV D

In the event of an explosion not only installations are at risk, but also people and the environment. Flames, radiated heat, pressure waves or flying debris can cause considerable damages and costs to companies.

The Rico slide valve is designed to be used in dust conveying pipes where pressure losses and obstacles are not desired.

The Rico Slide Valve is used in installations processing explosive dusts, gases or hybrid mixtures:

- Pharmaceutical industry

- Cosmetics industry

- Chemical/Petrochemical industry

- Research laboratories

- Silos, mills, drying chambers and separators

- Extraction systems, etc

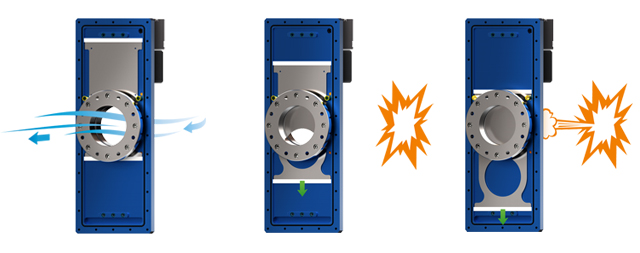

RICO RSV-D Slide Valves provide protection against the spread of explosions in dust transport systems.

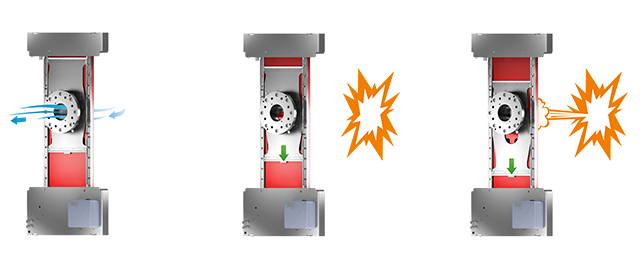

RSV-D provides protection in both directions.

The protected system is fitted with pressure and /or flame sensors. These detect an explosion and transmit a signal. Depending on the size of the Slide Valve, the signal activates one or more gas generators, which close the Slide Valve by means of the pressure generated. When closed, this effectively prevents the spread of flames and pressure waves. Fast closing times also allow short installation distances. The valve can be opened and closed pneumatically in normal operation.

- D: Dust, double acting

- for installations with dust transport

- maximum explosion pressure up to 30 bar.abs (≥ DN100)

- maximum explosion pressure up to 50 bar.abs (≥ DN80)

- rapid closing speeds

- short installation distance

- simple maintenance

- minimum downtimes due to rapid recommissioning after an explosion

- sizes DN50 to DN400 (other sizes available as special versions)

Rico – Slide Valve RSV-G

The RICO RSV-G Slide Valve provides effective protection from explosions in gas systems. Rico Sicherheitstechnik AG has developed an efficient explosion isolation slide valve which, with an external power supply, successfully prevents the spread of explosions in pipes.

- G: Gas, double acting

- for installations with dust, gas or mixture conveying

- maximum explosion pressure up to 30 bar.abs (≥ DN100)

- maximum explosion pressure up to 50 bar.abs (≥ DN80)

- rapid closing speed

- short installation distance

- simple maintenance

- minimum downtimes due to rapid recommissioning after an explosion

- sizes DN50 to DN400 (other sizes available as special versions)

- optimum cleaning in the product contact area (cip)

Rico – Slide Valve RSV-P

The RICO RSV-P Slide Valve provides explosion protection in both directions. Its special pharmaceutical-grade housing allows for optimum cleaning at the point of contact with product, both inside and outside.

- P: Pharmaceuticals, double acting

- for installations with dust, gas or mixture conveying

- maximum explosions pressure up to 30 bar.abs (≥ DN100)

- maximum explosions pressure up to 50 bar.abs (≥ DN80)

- rapid closing speeds

- short installation distance

- simple maintenance

- minimum downtimes due to rapid recommissioning after an explosion

- sizes DN100 to DN600 (other sizes available as special versions)

- optimum cleaning in product contact area (cip)

- special pharmaceutical housing offers optimum cleaning of outer product contact surfaces (wip)

WANT MORE TECHNICAL DETAILS? DOWNLOAD OUR DATASHEET.

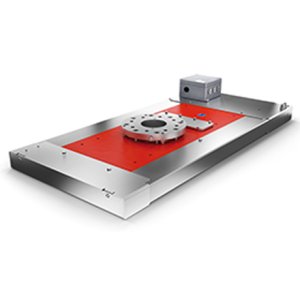

Rico – REDEX Slide

Do you need to protect a process with a high dust load and low explosion pressure? The explosion isolation slide valve, REDEX Slide, is the perfect solution thanks to its simple technical structure accompanied by attractive prices and low maintenance costs.

- for dust explosions, double acting

- for applications where explosion venting or suppression is used

- max. explosion pressure up to 2.5 bar.abs

- shortest closing times

- shortest installation distances

- easy maintenance

- minimal process breakdown due to fast recommissioning

- size DN80 to DN150

- suitable for indoor as well as outdoor installation

The protected system is fitted with pressure and/or flame sensors. These detect an explosion and transmit a signal. The signal activates a gas generator, which closes the slide valve through the generated pressure. The spread of flames and pressure waves is therefore effectively prevented. The extremely fast closing time enables very short installation distances. In normal operation, the slide valve can be opened and closed pneumatically.

WANT MORE TECHNICAL DETAILS? DOWNLOAD OUR DATASHEET.

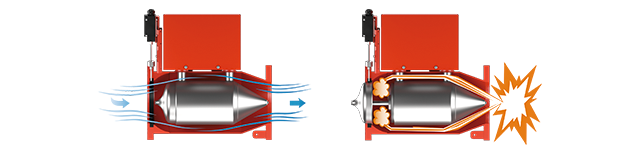

Rico – VENTEX ESI-P (discontinued model, only service and spare parts available)

The Rico VENTEX ESI-P active explosion protection valve is operated with external energy and, thanks to its specific functionality, also provides effective protection against fire.

- single-acting with external energy/active

- for gas, dust and hybrid mixtures

- closing via gas generator activeated by a system monitoring

- additionally prevents fires spreading

- coaxial design

- low pressure loss

- short installation distance

- rapid closing speed

- minimum downtime after an explosion

- sizes DN100 to DN500 (other sizes available as special versions)

- no soiling caused by the closing valve

- utilisation as a shut-off valve possible

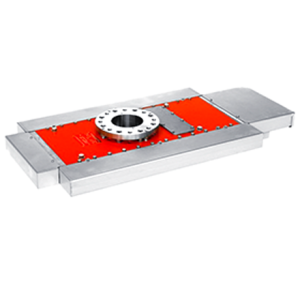

Rico REDEX® Ball Valve

The Rico REDEX® Ball is a game changer in the field of active explosion isolation. This innovative isolation solution is designed for product-carrying lines and processes. Unique in its design, the REDEX® Ball offers unparalleled durability, ease of use, and maintenance, ensuring utmost safety in explosive risk environments.

- The REDEX® Ball, an explosion isolation ball valve that prioritizes simple reliability. It presents an innovative concept in the market, providing a broad installation spectrum and easy handling.

- It operates compliantly with EN 15089, adhering to the ATEX Directive 2014/34/EU, NFPA 69, and is UKCA, FDA, and EC 1935/2004 certified.

- In its normal operation, the ball valve can be either open or closed depending on the pre-existing process and can be utilized as a shut-off valve.

- Post-explosion, it triggers a control system and pressure and flame sensors. The sensors detect an explosion and send a signal to the control unit. This unit subsequently activates a refined pneumatic actuation unit, which in reaction to pressure, closes the ball valve in a fraction of a second.

- Once closed, it effectively halts the spread of flames and pressure waves. This quick reaction time allows for shortest installation distances while also enabling more extended maximum installation distances.

WANT MORE TECHNICAL DETAILS? DOWNLOAD OUR DATASHEET.