Celebrating 25 Years 1999-2024

KITO – In-Line Detonation Flame Arresters

Our product line includes KITO® detonation flame arresters for all explosion groups and applications. When potentially explosive gas-air mixtures ignite in a pipeline section, a deflagration can sometimes become a detonation.

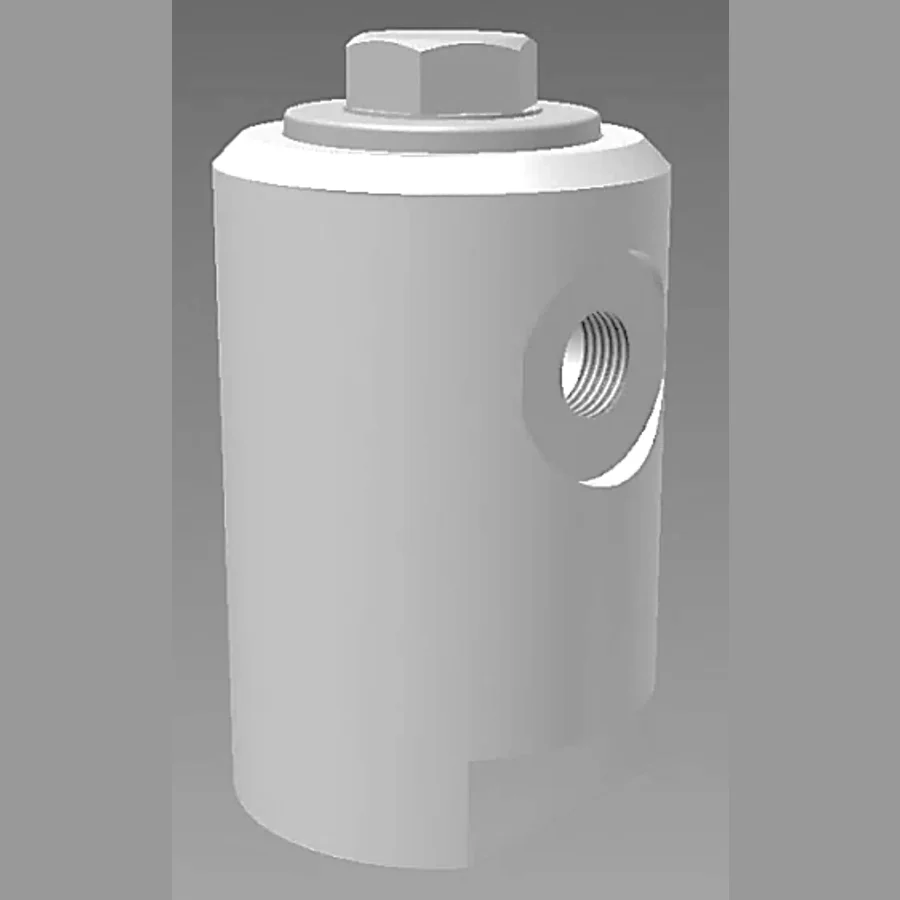

Uni-directional in-line detonation flame arrester

KITO® Rd/C-Det4-IIA-…-1.2

Detonation flame arrester for installation into pipes to protect containers and components against stable detonation of flammable liquids and gases.

Tested and approved as detonation flame arrester type 4.

Approved for all substances of explosion groups IIA1 to IIA with a maximum experimental safe gap (MESG) > 0.9 mm.

An operating pressure of 1.2 bar abs. and an operating temperature of 60°C must not be exceeded.

Positioning should be as close as possible to the protected object; it is only allowed to connect pipes with the same or a smaller diameter than the diameter (G) of the device.

The installation of the detonation flame arrester into horizontal and vertical pipes is permissible.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

Uni-directional in-line detonation flame arrester, short-time burning proof

For installation into pipes to protect containers and components against stable detonation of flammable liquids and gases.

Tested and approved as detonation flame arrester type 4.

Provided with one temperature sensor (PT 100) the armature is certified against short time burning from one side.

If only one thermal sensor is attached, it must be installed into that part of the body from which a fire is expected.

The installation is not dependent on the position and both directions of flow are possible. During installation, please observe the direction of detonation and the indication “protected side“.

- KITO® FD4-Det4-llB1-…-1.2: Approved for all substances of explosion groups IIA1 to IIB1 with a maximum experimental safe gap (MESG) ≥ 0.85 mm. Working unidirectional in pipes, whereby an operating pressure of 1.2 bar abs. and an operating temperature of 60°C must not be exceeded.

- KITO® FD4-Det4-llB-…: Approved for all substances of explosion groups IIA1 to IIB with a maximum experimental safe gap (MESG) ≥ 0.5 mm. Working unidirectional in pipes, whereby an operating pressure of 1.1 bar abs. and an operating temperature of 60°C must not be exceeded.

- KITO® FD4-Det4-llB3-…-1.2: Approved for all substances of explosion groups IIA1 to IIB3 with a maximum experimental safe gap (MESG) ≥ 0.65 mm. Working unidirectional in pipes, whereby an operating pressure of 1.2 bar abs. and an operating temperature of 60°C must not be exceeded.

- KITO® FD6-Det4-llB1-…-1.2: Approved for all substances of explosion groups IIA1 to IIB1 with a maximum experimental safe gap (MESG) ≥ 0.85 mm. Working unidirectional in pipes, whereby an operating pressure of 1.2 bar abs. and an operating temperature of 60°C must not be exceeded.

- KITO® FD6-Det4-llB3-…-1.2: Approved for all substances of explosion groups IIA1 to IIB3 with a maximum experimental safe gap (MESG) ≥ 0.65 mm. Working unidirectional in pipes, whereby an operating pressure of 1.2 bar abs. and an operating temperature of 60°C must not be exceeded.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

Bi-directional in-line detonation flame arrester, short-time burning proof

For installation into pipes to the protection of vessels and components against stable detonation of flammable liquids and gases.

Tested and approved as detonation flame arrester type 4. The installation of the detonation flame arrester into horizontal and vertical pipes is permissible.

Provided with one or two temperature sensors (PT 100) the armature is certified against short time burning from one or both sides.

If only one thermal sensor is attached, it must be installed into that part of the body from which a fire is expected.

- KITO® EFA-Det4-l-…/…-2.5,-T(-TT): Approved for all substances of explosion group IIA1 with a maximum experimental safe gap (MESG) ≥ 1.14 mm. Bi-directionally working in pipes, whereby an operating pressure of 2.5 bar abs. and an operating temperature of 60°C must not be exceeded.

- KITO® EFA-Det4-llA-…/…-1.2, -T(-TT): Approved for all substances of explosion groups IIA1 to IIA with a maximum experimental safe gap (MESG) > 0.9 mm. Bi-directionally working in pipes, whereby an operating pressure of 1.2 bar abs. and an operating temperature of 60°C must not be exceeded.

- KITO® CFA-Det4-llA-…/…-1.2, -T(-TT): Approved for all substances of explosion groups IIA1 to IIA with a maximum experimental safe gap (MESG) > 0.9 mm. Bi-directionally working in pipes, whereby an operating pressure of 1.2 bar abs. and an operating temperature of 60°C must not be exceeded. Equipped with two head pipes plugs for draining condensate.

- KITO® EFA-Det4-llA-…/…-X10, -T(-TT): Approved for all substances of explosion groups IIA1 to IIA with a maximum experimental safe gap (MESG) > 0.9 mm. Bi-directionally working in pipes, whereby an operating pressure of 1.1 bar abs. and an operating temperature of 100°C must not be exceeded.

- KITO® EFA-Det4-llA-…/…-X16, -T(-TT): Approved for all substances of explosion groups IIA1 to IIA with a maximum experimental safe gap (MESG) > 0.9 mm. Bi-directionally working in pipes, whereby an operating pressure of 1.1 bar abs. and an operating temperature of 160°C must not be exceeded.

- KITO® EFA-Det4-llA-…/…-1.2-X16, -T(-TT): Approved for all substances of explosion groups IIA1 to IIA with a maximum experimental safe gap (MESG) > 0.9 mm. Bi-directionally working in pipes, whereby an operating pressure of 1.2 bar abs. and an operating temperature of 160°C must not be exceeded.

- KITO® EFA-Det4-llA-…/…-1.2-X22, -T(-TT): Approved for all substances of explosion groups IIA1 to IIA with a maximum experimental safe gap (MESG) > 0.9 mm. Bi-directionally working in pipes, whereby an operating pressure of 1.2 bar abs. and an operating temperature of 220°C must not be exceeded.

- KITO® EFA-Det4-llA-…/…-…, -T(-TT): Approved for all substances of explosion groups IIA1 to IIA with a maximum experimental safe gap (MESG) > 0.9 mm. Bi-directionally working in pipes, whereby an operating pressure of 2.5 bar abs. up to NG 300, pmax = 2.0 bar abs. from NG 400 and an operating temperature of 60°C must not be exceeded.

- KITO® CFA-Det4-llA-…/…-…, -T(-TT): Approved for all substances of explosion groups IIA1 to IIA with a maximum experimental safe gap (MESG) > 0.9 mm. Bi-directionally working in pipes, whereby an operating pressure of 2.5 bar abs. up to NG 300, pmax = 2.0 bar abs. from NG 400 and an operating temperature of 60°C must not be exceeded. Equipped with two head pipes plugs for draining condensate.

- KITO® EFA-Det4-llB3-…/…-1.2, -T(-TT): Approved for all substances of explosion groups IIA1 to IIB3 with a maximum experimental safe gap (MESG) ≥ 0.65 mm. Bi-directionally working in pipes, whereby an operating pressure of 1.2 bar abs. and an operating temperature of 60°C must not be exceeded.

- KITO® CFA-Det4-llB3-…/…-1.2, -T(-TT): Approved for all substances of explosion groups IIA1 to IIB3 with a maximum experimental safe gap (MESG) ≥ 0.65 mm. Bi-directionally working in pipes, whereby an operating pressure of 1.2 bar abs. and an operating temperature of 60°C must not be exceeded. Equipped with two head pipes plugs for draining condensate.

- KITO® EFA-Det4-llB3-…/…-1.2-X16, -T(-TT): Approved for all substances of explosion groups IIA1 to IIB3 with a maximum experimental safe gap (MESG) ≥ 0.65 mm. Bi-directionally working in pipes, whereby an operating pressure of 1.2 bar abs. and an operating temperature of 160°C must not be exceeded.

- KITO® EFA-Det4-llC-…/…-1.2, -T(-TT): Approved for all substances of explosion groups IIA1 to IIC with a maximum experimental safe gap (MESG) < 0.5 mm. Bi-directionally working in pipes, whereby an operating pressure of 1.2 bar abs. and an operating temperature of 60°C must not be exceeded.

- KITO® RG-Det4-IIA-…-1.2, -T(-TT)-design with flange connection–KITO® RG-Det4-IIA-…-1.2, -T(-TT): Approved for all substances of explosion groups IIA1 to IIA with a maximum experimental safe gap (MESG) > 0.9 mm. Bi-directionally working in pipes, whereby an operating pressure of 1.2 bar abs. and an operating temperature of 60°C must not be exceeded. All sizes are tested against “stabilized burning” and withstand this up to a max. burn time BT = 30.0 min. To detect a “stabilized burning” a thermocouple must be installed at each endangered side. Mounting is acceptable in any position, in horizontal as well as in vertical pipes.

- KITO® RG-Det4-IIB3-…-1.2, -T(-TT)-design with flange connection-KITO® RG-Det4-IIB3-…-1.2, -T(-TT): Approved for all substances of explosion groups IIA1 to IIB3 with a maximum experimental safe gap (MESG) ≥ 0.65 mm. Bi-directionally working in pipes, whereby an operating pressure of 1.2 bar abs. and an operating temperature of 60°C must not be exceeded. All sizes are tested against “stabilized burning” and withstand this up to a max. burn time BT = 6.0 min. To detect a “stabilized burning” a thermocouple must be installed at each endangered side. Mounting is acceptable in any position, in horizontal as well as in vertical pipes.

- KITO® RG-Det4-IIC-…, -1.2, -T(-TT)-design with flange connection-KITO® RG-Det4-IIC-…, -1.2, -T(-TT): Approved for all substances of explosion groups IIA1 to IIC with a maximum experimental safe gap (MESG) < 0.5 mm. Bi-directionally working in pipes, whereby an operating pressure of 1.2 or 1.1 bar abs. and an operating temperature of 60°C must not be exceeded. All sizes are tested against “stabilized burning” and withstand this up to a max. burn time BT = 1.0 min. To detect a “stabilized burning” a thermocouple must be installed at each endangered side. Mounting is acceptable in any position, in horizontal as well as in vertical pipes.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!