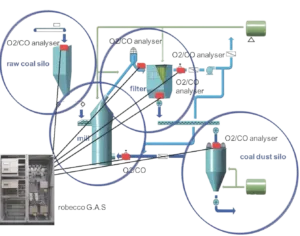

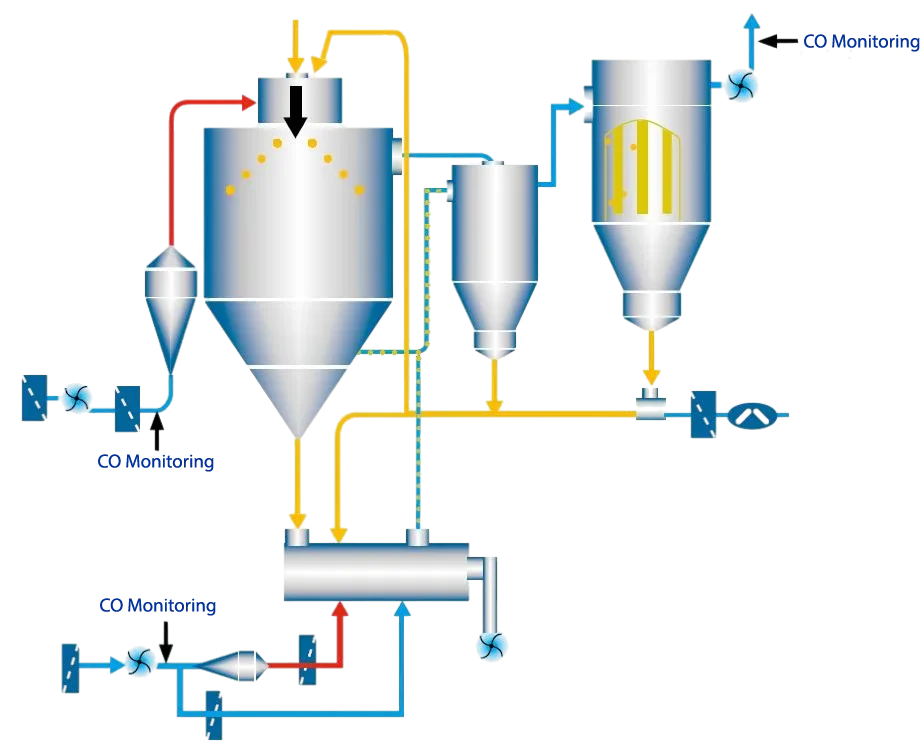

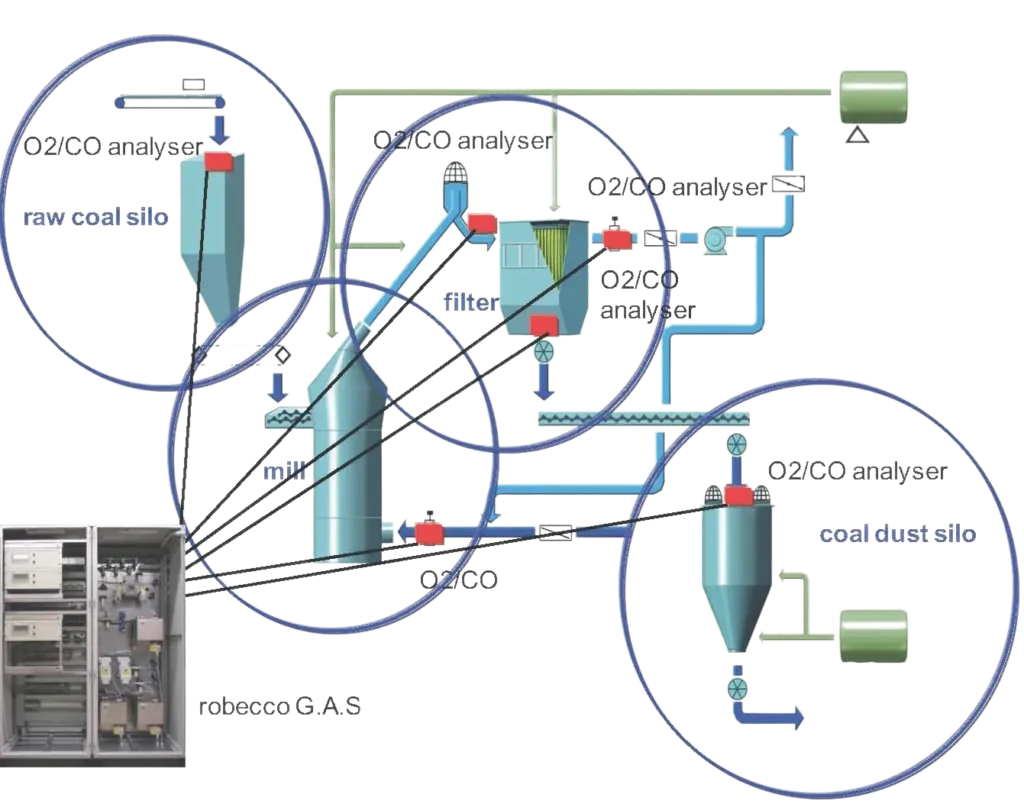

Early Smouldering Fire Detection / CO Monitoring Control System

The CO monitoring system prevents fire or dust explosions by monitoring spray dryer systems for smouldering nests or fires, detecting CO gas from product build-ups and thermal reactions, and enabling quick response with alarms, shutdowns, and activating water deluge systems.

WANT MORE TECHNICAL DETAILS? DOWNLOAD OUR DATASHEET.

Spray Dryer Protection

- Fires and Explosions generate a high risk for people, the environment, and production installations. The consequences are the significant development of heat and pressure.

- The fire and explosion safety of an installation is determined by the risk factors of the process and products.

- High drying temperatures and material product characteristics can develop dangerous smouldering areas in the production process

- The use of Carbon Monoxide (CO) Analysis for early fire detection is recommended according to VDI guideline 2263 part 7 and 7.1 and the robecco CO System is a proven technology.

- Early detection of smouldering fires allows the operators to mitigate fire propagation with the help of technical measures. Continuous Carbon Monoxide (CO) monitoring is essential to ensure the prevention of fires and explosions.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

Hazards And Ignition Sources

Dust Explosion Hazards exist in

- Mills

- Spray Dryers

- Dryers

- Filters – Dust Collectors

- Silos

- Conveyers

- Separators

- Dedusting Screens

- Mixers

Ignition Sources are

- Smouldering Nests

- Hot Surfaces

- Mechanically-Induced Sparks

- Sparking Electrical Equipment

- Flames

- Electrostatic Discharges

Product Sources are

- combustible dust in powder-air mixtures

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

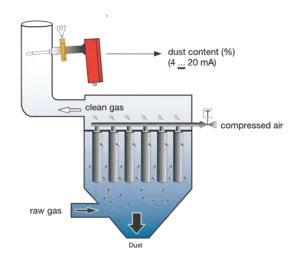

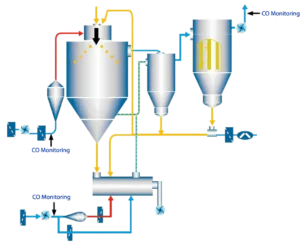

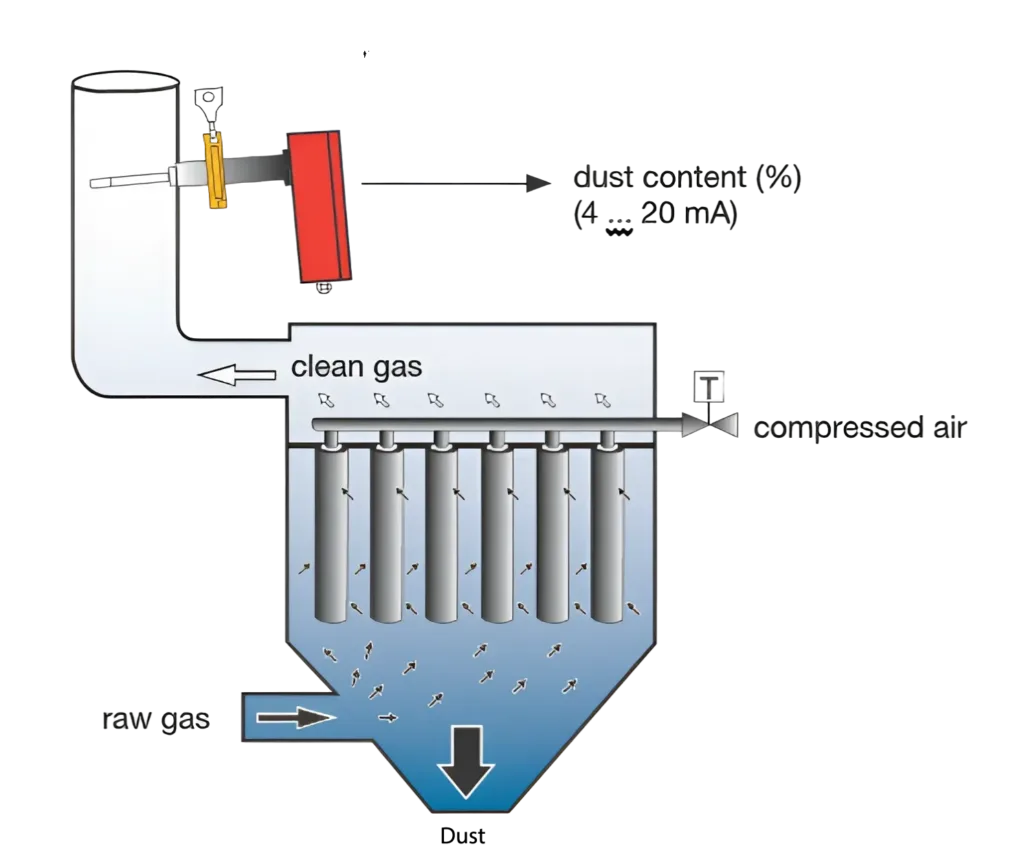

Robecco Dust Control (RDC)

Technical Characteristics

- Emission and filter monitoring with one device

- Avoidance of visible exhaust gas plumes

- Avoidance of product losses

- Simple erection and installation

Simple maintenance of filter installations because of

- Early detection of ongoing bag filter damage

- Location of damaged filter elements

- Opportunity for specific maintenance actions

Applications (examples): Emission and filter monitoring in

- Process filter

- Silo roof filter

- Dedusting systems

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!