Celebrating 27 Years 1999-2026

ELDRIDGE – Thermal Mass Flow Meters

Thermal mass flow meters from Eldridge Products, Inc. are state-of-the-art and can detect mass flow rates from very low to very high mass flow velocities, with an unparalleled level of accuracy.

Now Offering Flow Meter Field Validation For EPI Thermal Mass Flow Meter Calibration Validation (Epi-Val™) Site Validation of EPI Master-Touch & ValuMass Flow Meter Products.

Epi-Val™ Thermal Mass Flow Meter Calibration Validation

- Test Validates functionality of the Flow Meter sensor and associate circuitry.

- Test Validates thermal heat transfer properties of the sensor

- Test Validates the sensor is free of surface contamination buildup that could affect calibration.

- Test Validates a thermal heat transfer of a LiveZero™ test point at a no flow condition.

- Test Validates Flow Meter retains its NIST traceable calibration.

- Test Validates Flow Meter heat transfer repeatability.

- Test Validation data is stored in a user log showing Flow Meter specifications – serial number, date, time, milliwatt (mW) heat transfer value, allowable error percentage, and pass or fail. Validation test log report is printable.

- Test Validating Flow Meter, saves time and money in calibration related costs.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

Series 8000MP Master-Touch™ Flowmeters

In many industries the need for monitoring gas flow involves hazardous gases, potentially dangerous operating environments or simply a desire for a rugged, industrial-strength configuration. These applications include many common manufacturing processes, natural gas metering, compressed air auditing, etc. EPI’s Master-Touch MP Series is now approved for use in hazardous area locations:

IECEx – For use in hazardous area locations; T2 or T3 or T4 as marked; Ta = 0°C to 50°C;; Ex d IIB+H2 T2…T4 Gb IP66; Ex tD A21 IP66 T135°C…T300°C; IECEx CSA 11.0014

The remote enclosure is certified for use in Ordinary (Non-Hazardous) area locations: Type 4X, IP66

In the Master-Touch MP Series, the electronics enclosure at the point of measurement is approved for hazardous locations. In EPI’s integral style flowmeters, these electronics include all components including the flow rate and total display as well as a four-button keypad. Although their standard remote style configurations have a general purpose enclosure for installing at some distance from the point of measurement, explosion-proof enclosures for the remote electronics are also available.

WANT MORE TECHNICAL DETAILS? DOWNLOAD OUR DATASHEET.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

Series 8000MPNH Master-Touch™ Flowmeters

In many industries, the need for monitoring gas flow does not involve hazardous gases or potentially dangerous operating conditions. These applications can include many water and wastewater treatment applications, the HVAC industry, the general use of compressed air, and many other applications using air, nitrogen, argon, etc. In these cases, an explosion-proof electronics enclosure is not required, and may be considered a needless expense. To meet this challenge, Eldridge Products, Inc. now offers the Master-Touch™ Family of microprocessor-based thermal mass flowmeters in an economical enclosure suited to non-hazardous conditions.

In the MPNH Series, EPI has combined all of the features of their Master-Touch™ thermal mass flow meter technology with a convenient ABS enclosure. These new enclosures have a clear polycarbonate cover for viewing the rate and total display. Your installation requirements can be easily accommodated by your choice of in-line or insertion models with 115VAC, 230VAC, or 24VDC configurations, and with either integral or remote displays. The remote style models only need two conductors from the flow body electronics (5 ohm loop) — no local power is required. The cover can be easily removed for all input/output connections and for access to the 4-button keypad which provides direct control and adjustment of the flowmeter. Both integral and remote configurations are available. So now you can have the accuracy and flexibility of the Master-Touch thermal mass flowmeter for virtually all non-hazardous applications.

WANT MORE TECHNICAL DETAILS? DOWNLOAD OUR DATASHEET.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

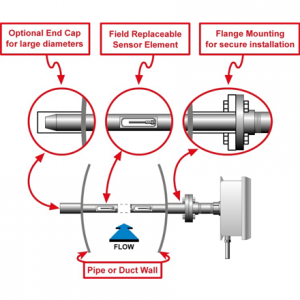

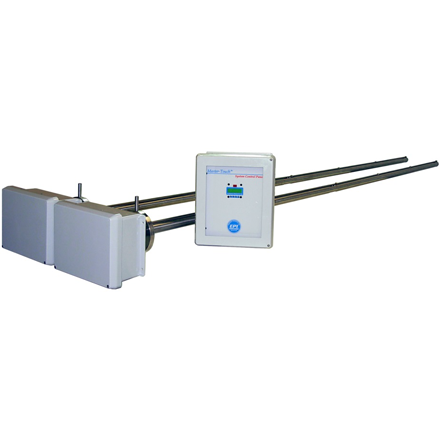

Master-Touch™ Flow Averaging Tubes (FAT™)

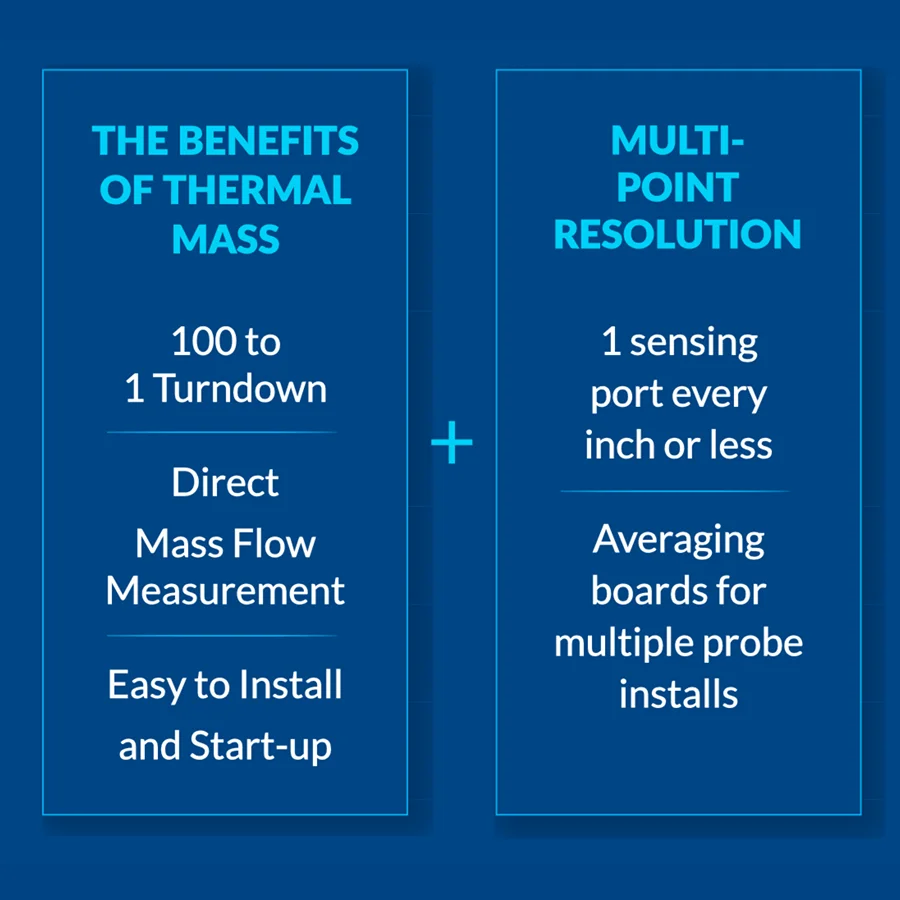

Eldridge Products, Inc.’s innovative new Flow Averaging Tubes (FAT™) provide accurate flow measurement in large pipes and ducts without the expense and complexity of traditional multipoint systems, offering a cost-effective solution for Heating, Ventilation, and Air Conditioning (HVAC) and Variable Air Volume (VAV) applications. They also provide accurate, repeatable readings in applications with very limited upstream straight-run. This patented technology combines the best elements of pitot tubes and thermal mass flow sensors. It works really well for applications such as combustion airflow.

MP Series FAT™ flowmeters are approved for use in hazardous locations. Series 9100MP-9200MP instruments have an explosion-proof flow transmitter mounted at the point of measurement with the signal processor electronics remotely mounted in a separate, general-purpose enclosure. An explosion-proof enclosure for the remote electronics is available as an option. The Series 9700MP-9800MP instruments have all electronics mounted at the point of measurement in an explosion-proof enclosure.

The Master-Touch MP Series FAT™ probes are now approved for use in hazardous area locations:

IECEx – For use in hazardous area locations; T2 or T3 or T4 as marked; Ta = 0°C to 50°C;; Ex d IIB+H2 T2…T4 Gb IP66; Ex tD A21 IP66 T135°C…T300°C; IECEx CSA 11.0014

The remote enclosure is certified for use in Ordinary (Non-Hazardous) area locations: Type 4X, IP66

MPNH Series FAT™ flowmeters are designed for installation in non-hazardous environments. They feature 5” x 5” x 4” ABS plastic enclosures. Series 9100MPNH-9200MPNH instruments have the flow transmitter mounted at the point of measurement with the signal processor electronics remotely mounted in a separate enclosure. Series 9800MPNH instruments have integral electronics mounted at the point of measurement.

Flow Averaging Tubes (FAT™) Advantages

- Provides the necessary mass flow measurement without needing an additional temperature transmitter and multivariable transmitter.

- Provides an accurate and repeatable measurement even for large flow ranges (high turndown).

- Requires far less straight run than a typical single point thermal mass flowmeter, and this application will have pipe sizes in the 12″ -20″ range.

- EPI’s flowmeter also comes standard with a process temperature measurement output. Eliminating the need for a temperature transmitter.

- The total installed cost for a solution with limited straight run (requiring flow conditioners) will be dramatically less with an insertion FAT probe and no flow conditioners. (Note that flow conditioners are often needed because of the large pipe diameters)

- Remote electronics allows the meters interface to be installed in a convenient location, the meter installation point will likely not be easily accessible.

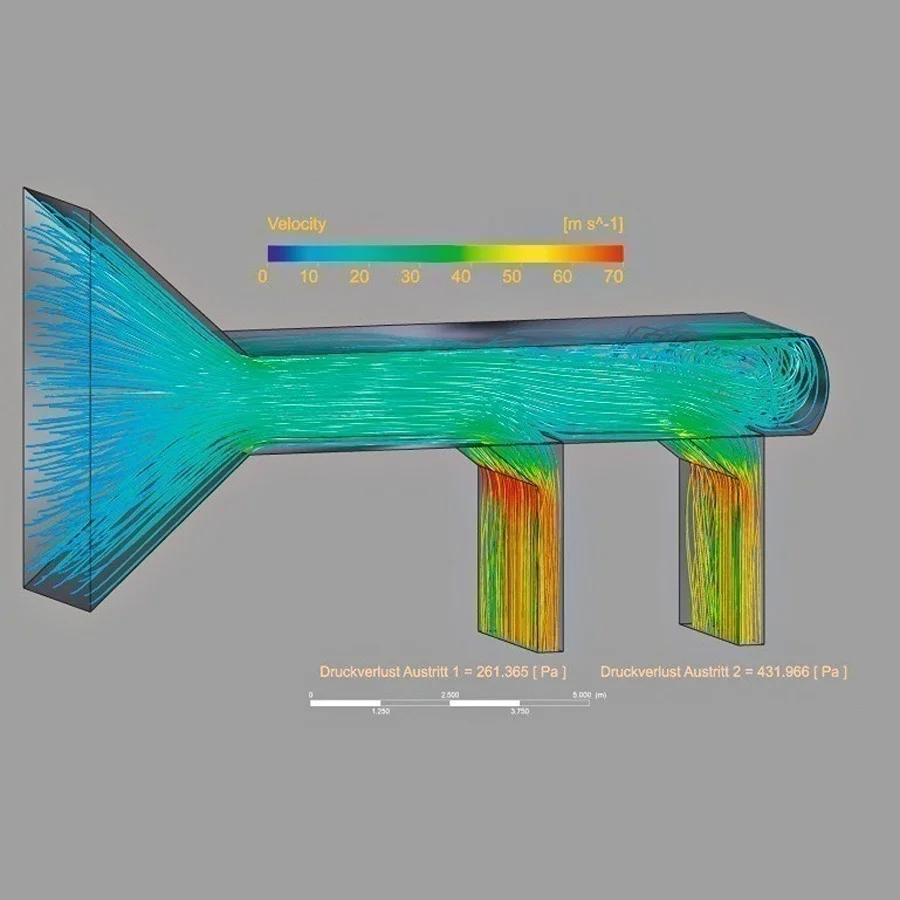

Flow Averaging Tubes (FAT™) Straight Run Requirement

The real-world accuracy of a flow measurement is more complicated than whatever you’d see on any flow transmitter’s datasheet. In order for a single-point flow measurement sensor to be within its specified performance, the flow profile must be “fully developed.” This is why every flow transmitter technology requires a minimum straight run, typically in pipe diameters.

Compared to other thermal mass manufacturers, the FAT probe from EPI requires a significantly lesser straight-run requirement. The FAT probe is sensing the flow in multiple places and doesn’t need the flow profile to be “fully developed.” Please refer to the image shown to learn its working principle.

Minimum required straight-run:

- Insertion probe, Thermal mass: 20-30 diameters

- Single point Thermal mass with flow conditioner upstream: 12 diameters

- EPI FAT probe: 5-7 diameters

The FAT Probe advantage for different pipe sizes

3” Pipe:

- Insertion probe, Thermal mass: 75”, height of Steph Curry

- EPI FAT Probe: 18”, diameter of one extra-large pizza

4” Pipe:

- Insertion probe, Thermal mass: 100”, height of a brown bear

- EPI FAT Probe: 24”, height of a bobcat

6” Pipe:

- Insertion probe, Thermal mass: 150”, length of a bull shark

- EPI FAT Probe: 36”, length of a golf club

12” Pipe:

- Insertion probe, Thermal mass: 300”, height of a maple tree

- EPI FAT Probe: 72”, height of Jeep Wrangler

18” Pipe:

- Insertion probe, Thermal mass: 450”, height of a standard telephone pole

- EPI FAT Probe: 108”, height of a room

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

Series 9000MP Master-Touch™ Multipoint Systems

Multipoint Systems are designed to measure gas flows where two or more sensing points are required due to large cross‐sectional areas, such as large air intake ducts or air exhaust and flue stacks. EPI’s Series 9000MP Multipoint Systems are installed throughout the world, providing EPI’s customers with years of steady, reliable service. Coupled with EPI’s new Air Purge System, the Series 9000MP Multipoint Systems are now well‐suited to an even greater variety of industrial applications.

The probe design supports applications as diverse as ambient air flows in HVAC ducts, exhaust gas in large diameter stacks, boiler NOx efficiency systems and municipal waste incinerators. EPI’s customers include environmental/HVAC system integrators, pulp & paper mills, power & energy companies, etc. across the US, Europe and Asia. The configuration and installation options support facility retrofits as well as the most modern new construction requirements

WANT MORE TECHNICAL DETAILS? DOWNLOAD OUR DATASHEET.

WANT MORE TECHNICAL DETAILS? DOWNLOAD OUR DATASHEET.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

Series 400 ValuMass™ Compact Mass & Insertion Stainless Steel Flow Meters

The Series 400 ValuMass™ flowmeters include 16-bit linearization technology for excellent flow rate accuracy and rugged construction of 316/316L stainless steel wetted parts.

The robust feature set includes:

· a 0 – 5 or 0 – 10 VDC output

· a 4 – 20mA output

· RS485 Modbus RTU communications

· a 0 – 1 kHz output proportional flow

· an RS232C port

· a 2-line, 16-character backlit LCD

· a programmable dry contact Relay for alarms or pulsed output totalization

ValuMass™ inline and insertion flowmeters accommodate virtually all installation requirements. The Series 400 inline style flow¬meters are available for line sizes from ¼” to 2”. The 3 ½” long flow sections have MNPT ends as standard for easy mounting in the process line. Other end fittings are available. The Series 440 insertion style flowmeters are available with 6”, 12” or 18” long probes which include a compression fitting. Other mounting options are available. ValuMass™ flowmeters accept 24VDC, 115VAC or 230VAC input power as specified at the time of purchase.

The ValuMass™ Series 400 is CE compliant.

WANT MORE TECHNICAL DETAILS? DOWNLOAD OUR DATASHEET.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

Series 500 ValuMass™ Thermal Dispersion & Duct Gas Flow Meters

The Series 500 ValuMass™ flowmeters include 16-bit linearization technology for excellent flow rate accuracy and rugged construction of 316/316L stainless steel wetted parts.

The robust feature set includes:

· a 0 – 5 or 0 – 10 VDC output

· a 4 – 20mA output

· RS485 Modbus RTU communications

· a 0 – 1 kHz output proportional flow

· an RS232C port

· a 2-line, 16-character backlit LCD and 4-button keypad

· a 2-line, 16-character backlit LCD and 4-button keypad

· a programmable dry contact Relay for alarms or pulsed output totalization

ValuMass™ inline and insertion style flow meters accommodate virtually all common installation requirements. The insertion style thermal flow meters are available with ½” OD probes in 6”, 12” or 18” lengths and a compression fitting is included with all insertion style flowmeters. The inline style flow meters are available for line sizes from ¼” to 2”. The 3 ½” long flow sections have MNPT ends as standard for easy mounting in the process line. ValuMass™ flowmeters accept 24VDC, 115VAC or 230VAC input power as specified at the time of purchase.

Now you can have the accuracy and reliability of an Eldridge Products’ thermal mass flow meter for applications that don’t require the full feature set of the Master-Touch™ product line.

The ValuMass™ Series 500 thermal flow meter is CE compliant.

WANT MORE TECHNICAL DETAILS? DOWNLOAD OUR DATASHEET.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

Series 7000-7200 Flow Switches

Eldridge Products, Inc. (EPI) Series 7000, 7100, and 7200 Flow Switches are rugged flow switches for gases. EPI’s flow switches are built with the same components as their flowmeters and operate on the same principals of thermal dispersion. They include two High/Low relays for High/High, Low/Low, and Low/High switch options. One second to thirty seconds time delay is a available as a standard, with automatic reset in one second upon resumption of non-fault flow conditions. Two LEDs provide verification that an alarm has been triggered. The flow switches are calibrated for your process conditions and the relay trip points can be easily set up in the field. Factory calibrated trip points are also available, at an additional charge.

Flow switches for non-hazardous locations are also available.

WANT MORE TECHNICAL DETAILS? DOWNLOAD OUR DATASHEET.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

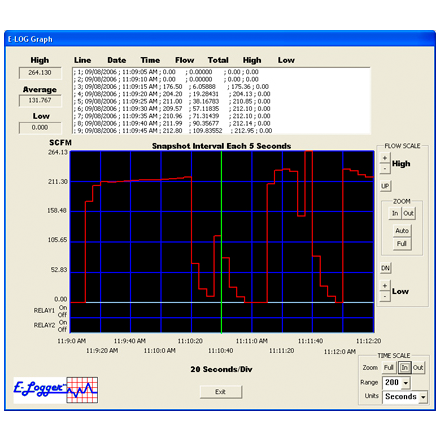

EPICommunicator™ (EPICom) Flowmeter Software

EPICommunicator™ (EPICom) is proprietary software for use with any Master-Touch™ flowmeter which has V3.9G or later software. It consists of four modules — EPITerm, EPIMeter, E-Logger™ and Modbus RTU — which work together to put complete control of the Master-Touch flowmeter in the hands of the user. EPICom uses the RS232, RS485 or USB communication protocol to connect a Master-Touch flowmeter to a PC running Windows XP® / Vista®.

EPITerm is a Windows XP® / Vista® compatible terminal emulation program which uses the RS232 or USB communications protocols to present the Master-Touch system for real-time monitoring and control.

E-Logger includes a fully functional, PC-based data logger that works in conjunction with Master-Touch™ flowmeters which have v4.1A and higher software. The user can select from a set of categories for the data collection, the time interval for each data “snapshot” and, if necessary, programmed start and stop times. The data is stored on either the flowmeter or a PC. E-Logger will also graph the data, and it provides tools for analysis of the data. Data files stored on a PC can be accessed by most common spreadsheet applications.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

LightWIRE Infrared Flow Meter Communications

Communicator I

The LightWIRE Communicator I modules can transmit and receive signals from both LightWIRE enabled flowmeters and LightWIRE Communicator III modules. When connected to a RS232 or USB port on a PC or laptop running EPI Communicator software, the LightWIRE Communicator I module replaces the three-wire cable for communications with an IR-Enabled Master-Touch™ flowmeter.

Communicator II

The LightWIRE Communicator II hand-held module is used as a substitute for the keypad/display assembly of IR-Enabled Master-Touch™ flowmeters. All of the flowmeters functions can be accessed without removing the flowmeter’s enclosure cover.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!