Celebrating 27 Years 1999-2026

CMC Technologies supplies active and passive explosion isolation solutions, including valves, detectors, control units and chemical suppressants, protecting dust handling, conveying and storage equipment across industrial processing applications.

Preventing Secondary Explosions Through Effective Explosion Isolation

Secondary explosions can cause extensive damage in an unprotected system, often due to inadequate explosion isolation in the ducting between vessels or connecting plant equipment. Weak enclosures like dust collectors, cyclones, bins, silos, and bucket elevators are typically only safeguarded with explosion venting, which may alleviate some over-pressure but still poses a risk of further damage without proper explosion isolation measures.

The explosion does not selectively travel through the explosion vent opening but can enter through all available openings, posing a significant hazard if it reaches connected equipment. To mitigate this risk, the use of explosion isolation products is crucial to protect plant equipment from the propagation of explosions between vessels.

Active Explosion Isolation

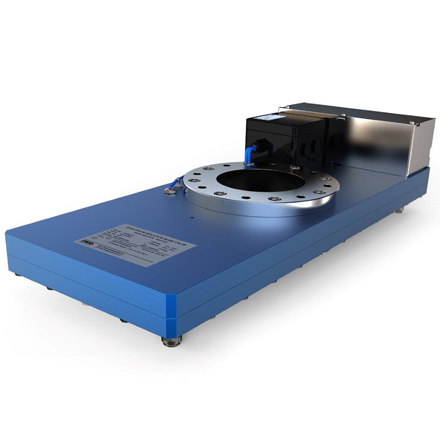

Active isolation systems, which differ from active isolation valves, necessitate the use of an explosion detector and control panel and encompass both chemical and mechanical isolation solutions. Mechanical isolation involves deploying a high-speed valve to create a barrier in the pipeline, protecting against flame and pressure propagation into interconnected vessels.

Examples include explosion protection guillotine valves/slide valves (e.g., Rico RSV) and explosion protection float valves (e.g., Rico ESI-P). On the other hand, chemical isolation utilizes explosion suppressant powder such as food-grade sodium bicarbonate or mono-ammonium phosphate to suppress the propagating flame front in the duct work between interconnected vessels.

IEP Technologies offers active system components like control units (EX100-1, EX200), dynamic explosion pressure detector, infrared and ultraviolet infrared detectors, and static explosion pressure detector, as well as IEP chemical isolation with the PHRD Suppressor. Rico Ventex provides explosion isolation valves like ESI-P, RSV-D, RSV-G, RSV-P, and REDEX Slide, offering a comprehensive range of active isolation solutions to enhance industrial safety.

Passive Explosion Isolation

Passive explosion isolation operates solely on the pressure wave from the explosion to activate the isolation mechanism, functioning without detection or control units.

Various solutions, such as the Brilex Isolation Valves (BPF-M and RSK – discontinued), Brilex Explosion Diverter (REXS), Thorwesten Vent Explosion Diverters (STT and DES), IEP Technologies Isolation Valve (ProFlapPlusII and IsoFlap), and Rico Ventex Isolation Valves (New Gen, ESI-D, ESI-E, ESI-C, and REDEX Flap), are available to provide passive explosion isolation.

These solutions offer a range of options for implementing passive isolation measures without the need for additional detection or control systems, enhancing safety in industrial environments.