Celebrating 27 Years 1999-2026

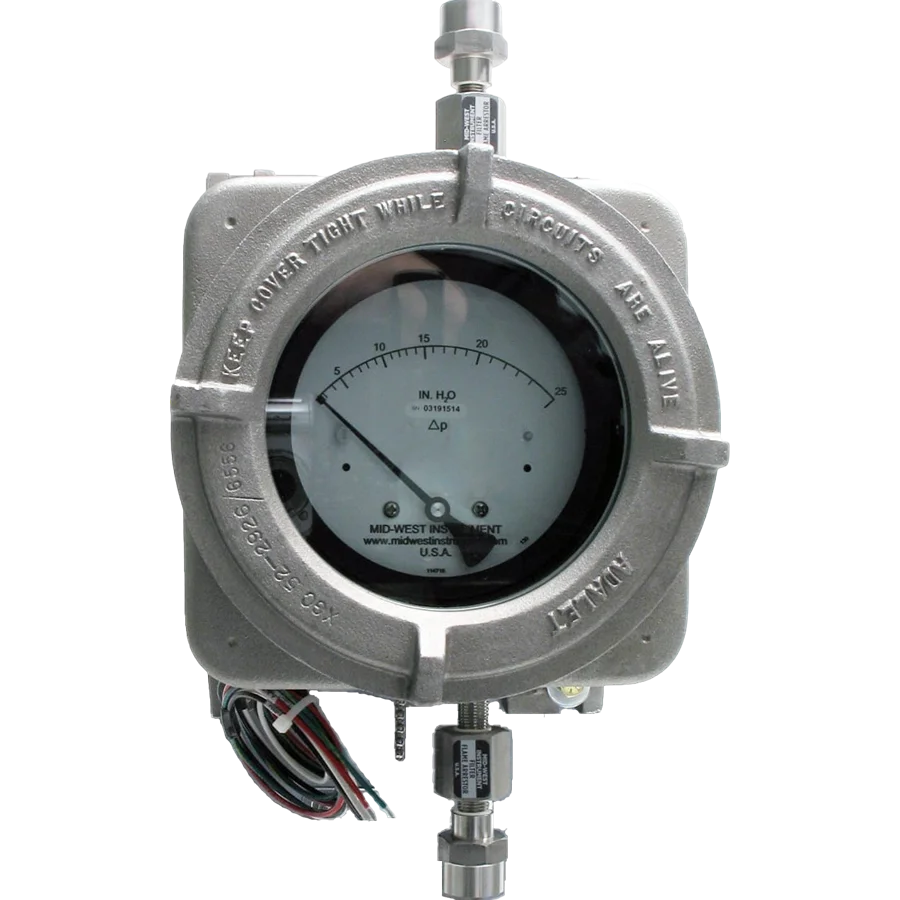

Differential Pressure Gauges & Switches for Hazardous Locations

CMC Technologies is proud to represent Mid-West Instrument’s complete line of differential pressure gauges and switches specifically for hazardous locations throughout Australia.

CMC Technologies authorised Distributor of Mid-West Instruments

With more than 30 years of experience in the industry, Mid-West is well known for producing dependable products that meet even the strictest safety standards, making it the perfect choice for your project.

Why Choose Mid-West Instruments?

- Over 30 years of proven field performance in hazardous locations

- Certified to CSA, UL, IECEx standards

- Fully RoHS and LVD compliant

- Certifications cover the entire assembly, not just enclosures

- Subject to 3-4 unannounced inspections annually by CSA and UL

- Undergoes yearly ATEX audits for ongoing compliance

- Fast production times — standard lead times are 7-10 business days.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

Hazardous Location Differential Pressure Switches & Transmitters

For more than thirty years, Mid-West Instrument has specialised in the design and manufacture of differential pressure switches for hazardous locations. Products are typically certified by CSA, UL, and ATEX, thus meeting international safety standards. The CE marking on products certified by ATEX also covers RoHS compliance.

These certifications apply to the overall design and construction of the product, as opposed to just the enclosure, so there is safety and reliability in whole. Our experienced sales coordinators will help you verify the appropriate certification for your particular application.

Custom Solutions Tailored to Your Needs

- Mid-West offers custom engineering options including:

- Dial size and design

- Process connection type and location

- Private label and OEM branding

- Colour dials, flow scales, and logo printing

Such flexibility ensures that you’ll receive pressure gauges and switches specifically tailored for your application, supported by one of the industry’s fastest turnaround times.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

Technical Highlights & Certifications

Hazardous Location Ratings:

Class 1 Division 1 & 2, Groups A-G; Class 2 Divisions 1 & 2

Explosion Proof Enclosures:

Ex d IIB + H2 IP65, Ex tb IIIC IP65

Accuracy:

Typically 2% full scale (ASME B40.100 Grade B)

Output Options:

SPST/SPDT switches, relay outputs, 4-20mA transmitters

Certification Bodies:

CSA, UL, IECEx, ATEX

Compliance:

RoHS & LVD compliant

Inspection Frequency:

3-4 unannounced CSA/UL inspections yearly; Annual ATEX audit

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

Explosion Proof Enclosure Models

- Model 120: Min DP Range 5 PSID, Max DP Range 110 PSID, Max Working Pressure up to 5000 PSIG

- Model 130: Min DP Range 5″ H2O, Max DP Range 400″ H2O, Max Working Pressure 500 PSIG

- Model 140: Min DP Range 25 PSID, Max DP Range 100 PSID, Max Working Pressure 3000 PSIG

- Model 220: Min DP Range 5 PSID, Max DP Range 100 PSID, Max Working Pressure up to 4000 PSIG

- Model 240: Min DP Range 20″ H2O, Max DP Range 100 PSID, Max Working Pressure 1500 PSIG

For expert advice on Mid-West hazardous location differential pressure gauges and switches or to place an order, contact CMC Technologies. Our team will ensure you get the right product with the required certifications and customised features to match your project’s needs.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!