Celebrating 27 Years 1999-2026

Composite Flat Type Rupture Discs – Bursting Discs

The FDC composite flat type rupture discs serve for safe pressure relief in an ever increasing range of critical applications.

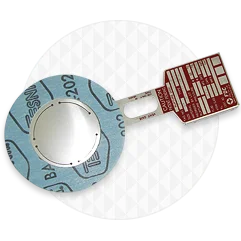

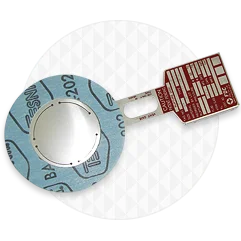

KSRO Composite Flat Type Rupture Discs

- KSRO Composite Flat Type for insertion between Flange bolts.

- Used with installation on Flange without the need of a holder

- Composite/Flat structure ruptured by precut slits on Top disc.

- The burst pressure is controlled by the combination of the CAF holes on the top section and the seal underneath.

- It consists of a Top disc, Seal disc (usually PTFE) and Vacuum disc (bottom section)

- Complies with rigorous standards, including ASME Code Sec.VIII, KS B ISO 4126, API RP520, KOSHA Code, and FDC Standard.

- Offers a wide size range from 1/2″ to 72″, accommodating a broad spectrum of installation needs.

- Features an adjustable setting pressure from 0.3 to 35kg/㎠, catering to diverse operational requirements.

- Capable of withstanding maximum temperatures up to 482℃, ensuring durability in high-temperature applications.

- Constructed from various materials like C.S, SUS, Duplex, Nickel, Inconel, and others, allowing for use in multiple process environments.

- Intended for processing gas, vapor, and liquid media, demonstrating its versatility for different industrial applications.

- Boasts a maximum operating ratio of 50%, ensuring performance reliability without the generation of sparks.

- Offers optional features such as pressure gauges, burst sensors, and additional safety and monitoring features to enhance system integrity.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

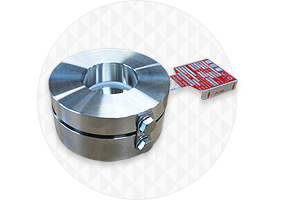

KSROH Composite Flat Type Rupture Discs

- The KSROH model is a Composite Flat Type designed for installation on FDC standard holders.

- Adheres to various standards including ASME Code Sec.VIII, KS B ISO 4126, API RP520, KOSHA Code, and FDC Standard.

- Available in sizes ranging from 1/2″ to 48″ to accommodate different installation requirements.

- Features a broad setting pressure range from 0.05 to 35kg/㎠, catering to various operational needs.

- Can operate at temperatures up to 482℃, ensuring reliability under high thermal conditions.

- Constructed from diverse materials such as C.S, SUS, and special alloys like Inconel, Monel, and Titanium, providing flexibility for specific process requirements.

- Suitable for gas, vapor, and liquid media, making it versatile for different industrial applications.

- Ensures a maximum operating ratio of 50% without spark generation, enhancing safety.

- Offers optional features including a pressure gauge, burst sensor, and alarm system for enhanced monitoring and safety.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

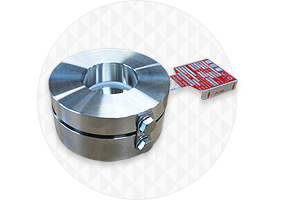

KSROF Composite Flat Type Rupture Discs

- The KSROF model is a Composite Flat Type specifically designed for Ferrule Connection installations without a holder.

- Meets numerous standards like ASME Code Sec.VIII, KS B ISO 4126, API RP520, KOSHA Code, and adheres to FDC Standard.

- This model is available in sizes ranging from 1S to 4S Ferrule, offering a variety of options for different system requirements.

- Offers a setting pressure range from 0.05 to 15kg/㎠, suitable for a wide range of operational pressures.

- Capable of withstanding temperatures up to 482℃, making it ideal for high-temperature environments.

- Manufactured from a diverse array of materials including C.S, SUS, Duplex, and exotic alloys like Hastelloy and Tantalum, providing suitability for various process media.

- Specifically designed for handling gas, vapor, and liquid, thereby ensuring versatility across different applications.

- Operates effectively at a maximum operating ratio of 50%, ensuring reliability and safety without the risk of sparking.

- Features optional enhancements such as pressure gauges, burst sensors, and various coatings like PFA/PTFE for improved performance and monitoring.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!