Celebrating 27 Years 1999-2026

Composite Dome Type Bursting Discs – Rupture Discs

FDC, possessing 25 years experience in rupture discs, provide products fulfilling standards including KS B ISO 4126, ASME Section VIII . Composite domed discs ensure precise operation from full vacuum to 80% burst pressure, added by laser-cut top section and seal to stop leakage.

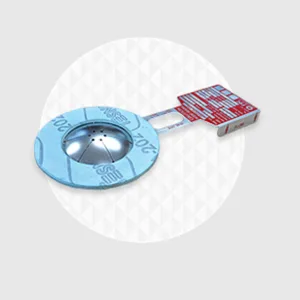

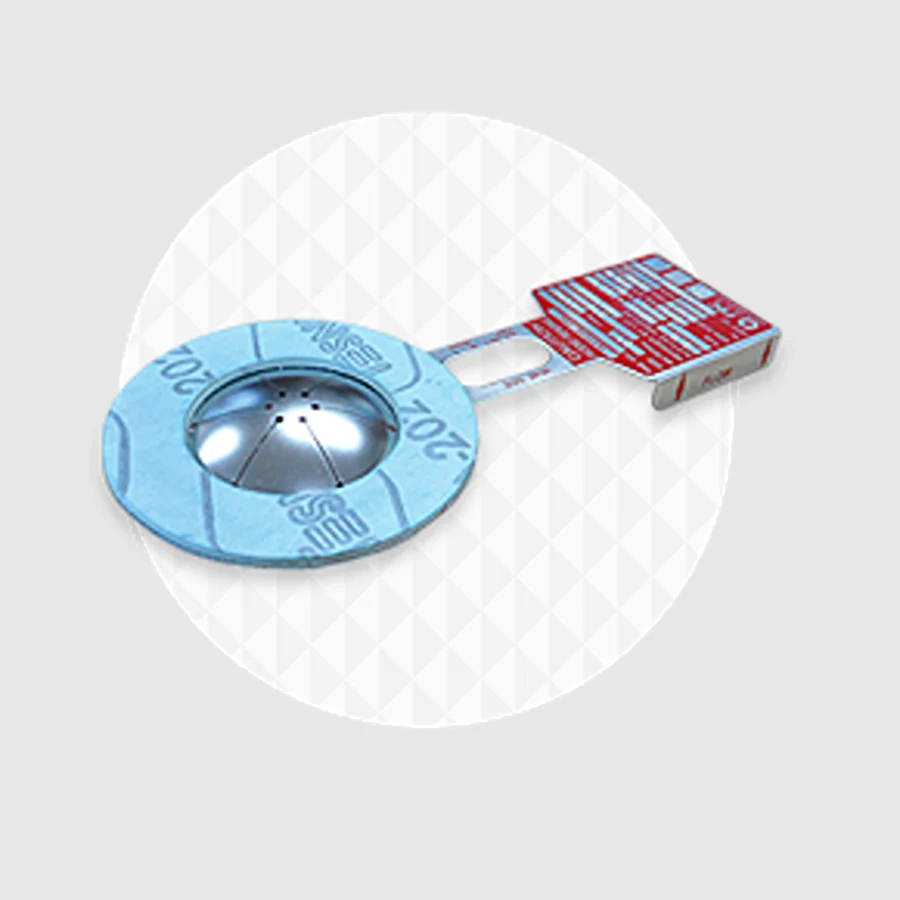

KSRC Composite Rupture Disc with Holder

- Suitable for liquid and steam media

- Counterpressure, vacuum, pulsation conditions compatibility

- Vacuum Support option available

- Precise rupture performance

- Reliability for medium to high pressure

- Corrosion resistance varies with Seal disc material

- Temperature range limited by Seal disc material

- Composite Dome Sloped Seat Type design

- Used with FDC standard holder installation

- Structure: Top disc, Seal disc, Vacuum disc

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

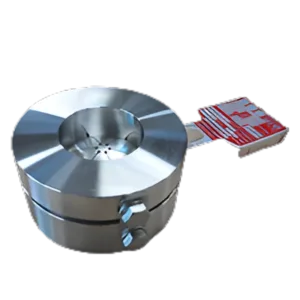

KSRRCH Composite Rupture Disc with Holder

- Versatile for liquid or steam media

- Counterpressure, vacuum, pulsation condition performance

- Vacuum support available

- Suitable for mid to low-pressure applications

- Corrosion resistance based on Seal disc materials

- Temperature range depends on Seal disc material

- Composite Dome Flat Seat Type design

- Uses FDC standard holder for installation

- Structure includes Top disc, Seal disc, Vacuum disc

- KSRRC variant for Flange installation without holder

- KSRRCF variant for Ferrule Connection without holder

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

KSRRC Composite Rupture Disc

- The KSRRC model is designed as a Composite Dome Flat Seat Type specifically for Flange installation without a holder.

- It conforms to industry standards including ASME Code Sec.VIII, KS B ISO 4126, API RP520, KOSHA Code, and FDC Standard.

- This model offers sizes from 1/2″ to 52″, accommodating a wide range of installation needs.

- Features a set pressure range from 0.3 to 100kg/㎠, enabling various operational pressures.

- Constructed from materials such as C.S, SUS, Duplex, and exotic alloys like Inconel, Monel, and Titanium, suitable for different process environments.

- Designed to handle gas, vapor, and liquid media, highlighting its flexibility for industrial applications.

- Maintains a maximum operating ratio of 80%, ensuring reliability under specific operational conditions without sparking.

- Offers optional features like pressure gauges, burst sensors, and PFA/PTFE coating among others for enhanced functionality and safety.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

KSRRCF Composite Rupture Disc

- The KSRRCF model is a Composite Dome Flat Seat Type crafted for Ferrule Connection installations without a holder.

- Adheres to significant standards such as ASME Code Sec.VIII, KS B ISO 4126, API RP520, KOSHA Code, and the FDC Standard.

- Available in sizes from 1S to 4S Ferrule, providing options for various system requirements.

- Constructed from a variety of materials including C.S, SUS, Duplex, and exotic alloys like Hastelloy, Titanium, ensuring compatibility with diverse processing conditions.

- Specifically engineered to process gas, vapor, and liquid media, showcasing versatility in application.

- Operates with a maximum operating ratio of 80%, offering stable performance under specified conditions without sparking issues.

- Includes options for customization and enhanced performance, such as pressure gauges, burst sensors, and PFA/PTFE coating, among others.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!