Celebrating 27 Years 1999-2026

CMC supplies KITO end of line flame arresters that prevent flames from entering pipes or vessels. KITO offers a variety of equipment for installations that include a breather/venting safety device with a flame arrester for deflagration explosions.

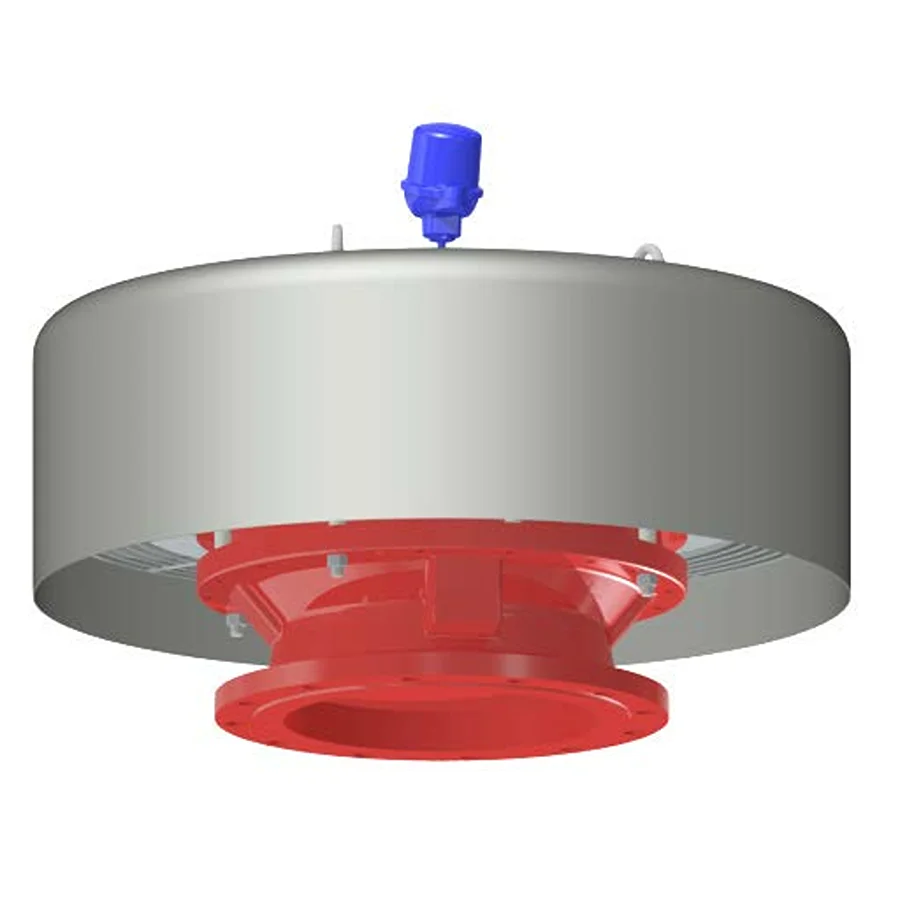

KITO® VH-IIB3 Deflagration Proof Ventilation Hood

The KITO® VH-IIB3 Deflagration Proof Ventilation Hood is engineered for safety and efficiency in hazardous environments. This essential breather and venting safety device is ideal for installations on storage tanks, tank access covers, and breather pipes. It facilitates the unimpeded flow of gases to the atmosphere while allowing air to enter, preventing vacuum locks and providing reliable protection against flashbacks.

Key Features

- Explosion Proof Design: Certified for materials in explosion group IIB3, equipped with a flame arrester element for maximum safety.

- Performance: Maximum experimental safe gap (MESG) of ≥ 0.65 mm and operating temperature up to 60 °C.

- Versatile Sizes: Available from DN 50 to DN 800, tailored for various operational needs.

- Durable Materials: Options include cast steel and stainless steel, with an interchangeable flame arrester element for easy maintenance.

- Compliance: Meets EN ISO 16852 and ATEX Directive 2014/34/EU standards.

KITO® VH-IIB3-XT Deflagration and Short-Time Burning Proof Ventilation Hood

The KITO® VH-IIB3-XT Deflagration and Short-Time Burning Proof Ventilation Hood is specifically designed for installations on storage tanks. This end-of-line venting device incorporates an explosion and short-time burn proof flame arrester to protect flammable products classified in explosion group IIB3, ensuring safe operations in hazardous environments.

Key Features

- Advanced Safety Design: Equipped with a flame arrester element that provides protection against flashbacks, enhancing safety during operations.

- High Operating Temperature: Suitable for a maximum operating temperature of 180 °C with a maximum experimental safe gap (MESG) of ≥ 0.65 mm, making it ideal for challenging conditions.

- Inbreathing and Out-Breathing: Allows for safe gas exchange while preventing the risk of flashbacks into the tank.

- Temperature Sensor: Features a built-in temperature sensor to detect stabilized burning conditions (burn time of 1 minute), ensuring timely response to potential hazards.

- Versatile Installation: Designed for use on top of storage tanks, tank access covers, or at the end of breather pipes, providing flexibility in application.

Technical Specifications

- Models Available: Sizes range from DN 50 to DN 400, with corresponding weights and dimensions for each model.

- Compliance: Conforms to EN ISO 16852 and ATEX Directive 2014/34/EU standards, reassuring users of its reliability and safety.

KITO® VH-IIB3-T Deflagration and Short-Time Burning Proof Ventilation Hood

The KITO® VH-IIB3-T Hooded Tank Vent is designed as a breather and venting safety device for installations on top of storage tanks, tank access covers, or breather pipes. Incorporating an explosion and short-time burn proof flame arrester element, this device ensures the safe flow of gases while preventing flashbacks into the tank.

Key Features

- Enhanced Safety Design: Features an explosion-proof flame arrester that allows for the unimpeded flow of gases to the atmosphere, preventing vacuum locks and ensuring reliable protection.

- Temperature Monitoring: Includes a PT 100 temperature sensor to detect stabilized burning conditions (burn time of 1 minute), enhancing operational safety.

- Versatile Applications: Suitable for use with materials in explosion group IIB3, with a maximum experimental safe gap (MESG) of ≥ 0.65 mm.

- Durable Construction: Made from high-quality materials including cast steel and stainless steel, ensuring longevity and resistance to corrosion.

- Compliance: Adheres to DIN EN ISO 16852 standards and ATEX Guideline 94/9/EC, providing peace of mind in hazardous environments.

Technical Specifications

- Models Available: Ranges from DN 50 to DN 800, with corresponding weights and dimensions tailored for each model.

- Flange Connection: Designed with a flange connection per DIN EN 1092-1 form B1 and ANSI 150 lbs. RF for secure installation.

KITO® VH-IIC Deflagration Proof Ventilation Hood

The KITO® VH-IIC Deflagration Proof Ventilation Hood is designed as a breather and venting safety device for installation on top of storage tanks, tank access covers, or breather pipes. This device incorporates an explosion-proof flame arrester element, ensuring the safe flow of gases while preventing flashbacks into the tank.

Key Features

- Explosion-Proof Design: Equipped with a flame arrester to provide reliable protection against flashbacks, making it ideal for hazardous environments.

- High Safety Standards: Approved for materials in explosion group IIC with a maximum experimental safe gap (MESG) of < 0.5 mm and a maximum operating temperature of 60 °C.

- Unimpeded Gas Flow: Facilitates the free flow of gases to the atmosphere while allowing air to enter the tank or pipe, preventing vacuum locks.

- Durable Construction: Built with high-quality materials to withstand demanding conditions, ensuring longevity and performance.

- Compliance: Meets EN ISO 16852 standards and ATEX Directive 2014/34/EU, ensuring adherence to safety regulations.

Technical Specifications

- Models Available: Sizes range from DN 50 to DN 800, with specific weights and dimensions tailored for each model.

- Flange Connection: Designed with a flange connection suitable for various applications.

KITO® VH-IIC-T Deflagration and Short-Time Burning Proof Ventilation Hood

The KITO® VH-IIC-T Deflagration and Short-Time Burning Proof Ventilation Hood is designed as a breather and venting safety device for installation on top of storage tanks, tank access covers, or breather pipes. This device incorporates an explosion and short-time burn proof flame arrester element, ensuring safe gas flow while preventing flashbacks into the tank.

Key Features

- Superior Safety Design: Features an explosion-proof flame arrester that allows for the unimpeded flow of gases to the atmosphere, enhancing safety in hazardous environments.

- Temperature Monitoring: Equipped with a temperature sensor to detect stabilized burning conditions (burn time of 1 minute), providing added safety during operations.

- High Safety Standards: Approved for materials in explosion group IIC, with a maximum experimental safe gap (MESG) of < 0.5 mm and a maximum operating temperature of 60 °C.

- Durable Construction: Made from high-quality materials to withstand demanding conditions, ensuring longevity and performance.

- Compliance: Meets EN ISO 16852 standards and ATEX Directive 2014/34/EU, assuring users of its reliability and adherence to safety regulations.

Technical Specifications

- Models Available: Sizes range from DN 50 to DN 800, with specific weights and dimensions tailored for each model.

- Flange Connection: Designed with a flange connection suitable for various applications.

KITO® VEH-4-IIB3 and VEH-5-IIB3 Deflagration Proof Ventilation Hoods

The KITO® VEH-4-IIB3 and KITO® VEH-5-IIB3 Deflagration Proof Ventilation Hoods are designed as breather and venting safety devices for small tank facilities. These units are explosion-proof, specifically designed for flammable fluids classified in explosion group IIB3, providing essential safety in hazardous environments.

Key Features

- Explosion-Proof Design: Incorporates a flame arrester element that prevents the passage of flames into the tank, ensuring the highest safety standards.

- Unimpeded Gas Flow: Allows gases to enter the storage medium freely while venting to the atmosphere, preventing vacuum locks.

- High Operational Standards: Approved for use with a maximum operating temperature of 60 °C and a gap width (NSW) of ≥ 0.65 mm.

- Durable Construction: Available in steel or stainless steel, ensuring long-lasting performance and resistance to corrosion.

- Flexible Installation: Suitable for installation on storage tanks, tank covers, or at the end of ventilation pipes.

Technical Specifications

- Models Available:

- KITO® VEH-4-IIB3: Available in G ½” and G ¾” sizes.

- KITO® VEH-5-IIB3: Available in G 1” and G 1 ¼” sizes.

- Flange Connection: Designed with threaded formats or flanges per EN 1092-1 type A and ASME B16.5 Class 150 RF.

Key Applications and Advantages of KITO®

Common Applications

This ventilation hood is ideal for industries handling flammable gases, including:

- Chemical Processing

- Oil and Gas Storage

- Wastewater Treatment

- Pharmaceutical Manufacturing

- Hazardous Material Management

Why choose KITO® end of line flame arresters?

When selecting a deflagration-proof ventilation system or explosion-proof safety equipment, consider the KITO® VH-IIB3 for its robust safety features, compliance with industry standards, and versatile applications. This product ensures reliable performance in critical environments, meeting the needs of safety-conscious professionals and industries focused on preventing dangerous gas buildup.