Celebrating 27 Years 1999-2026

Early Warning Fire Detection, Smouldering Detection and CO Monitoring Control System

CMC supplies Robecco Early Warning Fire Detection CO System and Robecco Dust Control solutions that help detect smouldering fires early, reduce risks, prevent contamination, and maintain high productivity levels.

Understanding Fire and Explosion Risks

Fires and explosions present significant risks to people, the environment, and production facilities. These incidents can lead to severe heat and pressure build-up. The safety of any installation depends on the risk factors associated with its processes and products.

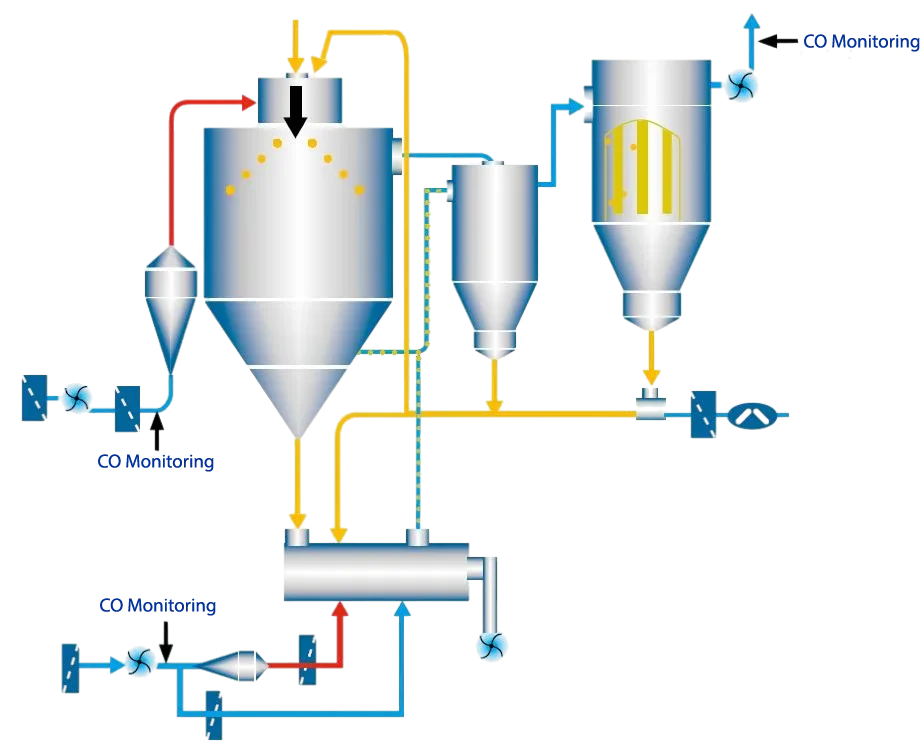

In the spray drying process, high temperatures and the properties of materials can create dangerous smouldering fires. To address this, the use of Carbon Monoxide (CO) analysis for early fire detection is highly recommended. This method follows the VDI guideline 2263, parts 7 and 7.1, which outlines proven technology for fire safety.

Early detection of smouldering fires allows operators to take action to stop the spread of fire. Continuous monitoring of Carbon Monoxide (CO) is essential to prevent fires and explosions.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

Dust Explosion Hazards

Dust explosions can occur in various settings, including:

- Mills

- Spray dryers

- Dryers

- Filters and dust collectors

- Silos

- Conveyors

- Separators

- Dedusting screens

- Mixers

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

Ignition Sources

Common ignition sources that can lead to fires include:

- Smouldering nests

- Hot surfaces

- Mechanically-induced sparks

- Sparking electrical equipment

- Flames

- Electrostatic discharges

These sources can ignite combustible dust in powder-air mixtures, increasing the risk of explosion. To minimise this, you can use the robecco Dryer Protection and robecco Dust Control System.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

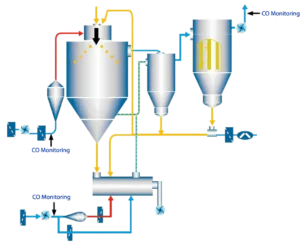

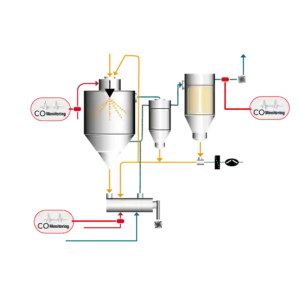

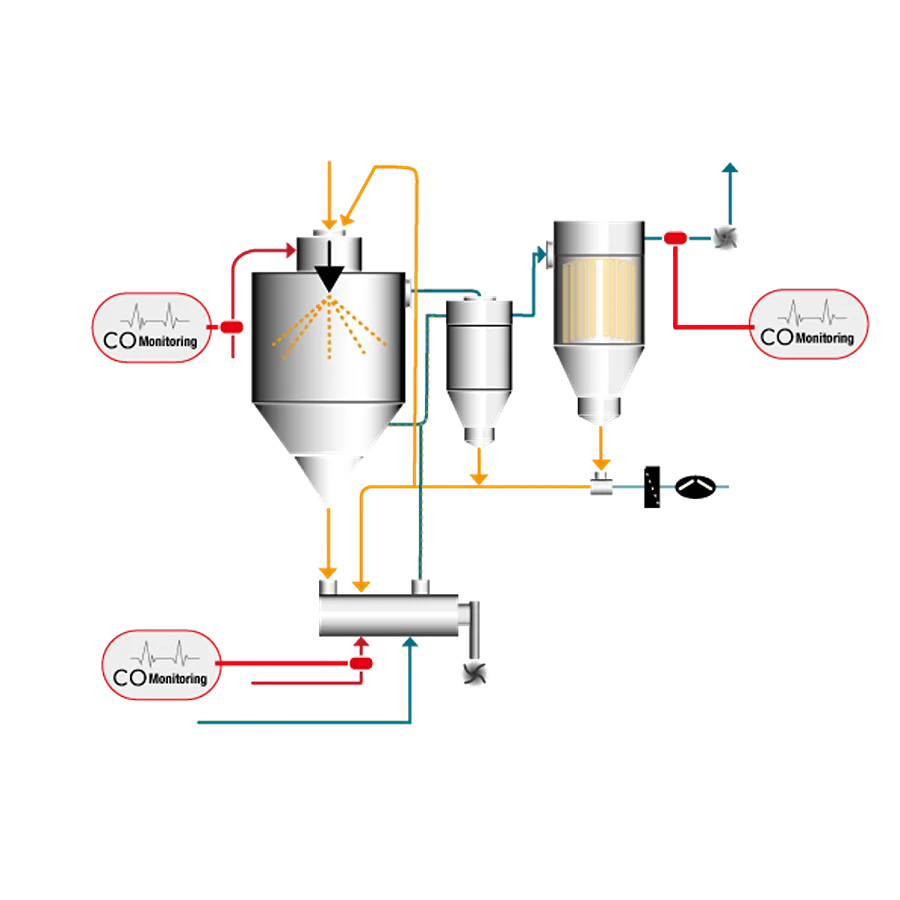

Robecco Dryer Protection (RDP)

The Robecco Dryer Protection (RDP) system is designed to prevent production stops and ensure productivity.

Technical Characteristics

RDP offers several key features:

- Continuous infrared differential CO measurement

- ATEX conformity for safety

- Heated sample probes and sample lines

- Compact construction for easy integration

- User-friendly operation for all staff

- Real-time visualisation of measurements

- Simple and cost-effective maintenance

- Minimal spare parts required

- Data memory for tracking performance

- Failure indication alerts for immediate action

- Redundant CPU system on demand for reliability

- Drift compensation scheduling for accuracy

- Automatic maintenance monitoring to keep systems running smoothly

- Flexible user administration for tailored access

Common Applications

The RDP system is effective in early fire detection during drying processes for milk, coffee, cocoa, sugar, malt, tea, fruit concentrate and blood

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

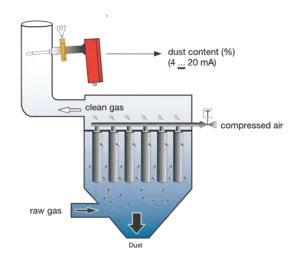

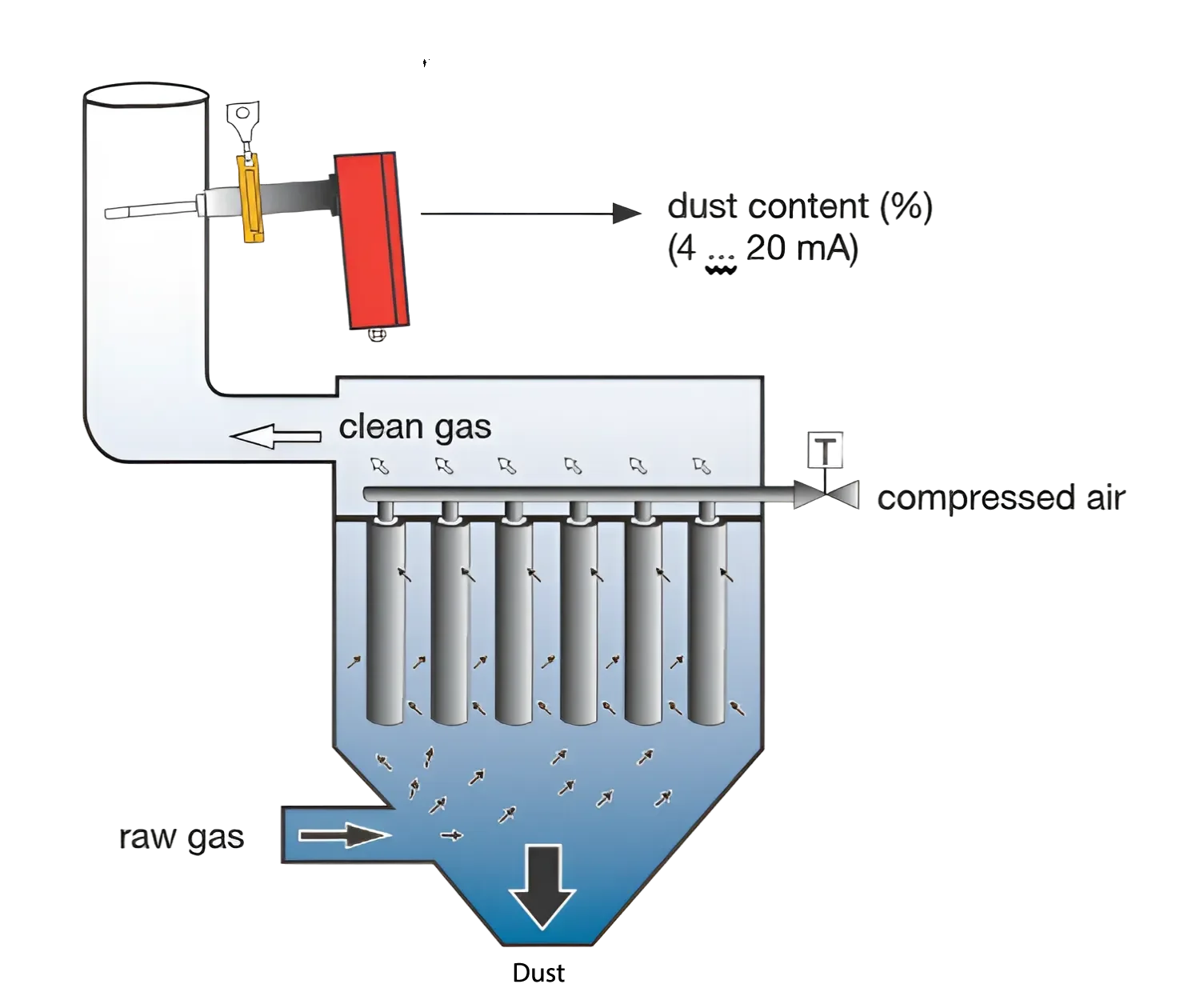

Robecco Dust Control (RDC)

The Robecco Dust Control (RDC) system identifies damage in filter separators effectively. It optimises emissions and filter monitoring to guarantee high productivity.

Technical Characteristics

Key features of the RDC include:

- Emission and filter monitoring in one device

- Avoidance of visible exhaust gas plumes

- Prevention of product losses due to leaks

- Simple installation and setup

Maintenance Benefits

The RDC simplifies maintenance in filter installations by providing:

- Early detection of ongoing bag filter damage

- Location identification of damaged filter elements

- Opportunities for specific maintenance actions before major issues arise

Common Applications

Robecco Dust Control is suitable for emission and filter monitoring in process filters, silo roof filters, and dedusting systems.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

The Robecco Early Warning Fire Detection CO System and Robecco Dust Control solutions are crucial for ensuring safety in food production. They facilitate the early detection of smouldering fires, reduce risks, prevent contamination, and support high productivity levels. Choose these systems to safeguard your operations against the threats of fires and explosions.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!