Celebrating 27 Years 1999-2026

CMC Technologies supplies Mid‑West pulsation dampeners, pressure limiting valves and manifolds, protecting gauges and transmitters across industrial process applications with adjustable control, high‑pressure ratings, leak‑free design and proven overpressure protection.

Mid-West Model 150 Pulsation Dampener

- The Model 150 “Vari-Damp®” serves as a versatile pulsation dampener with dual functionality.

- Equipped with a fine thread needle valve, allowing for precise dampening adjustments.

- Features a Precision Controlled Flow Rate Ball Check, designed to prevent line surges, shock waves, and fluid hammer.

- Adjustable while the unit remains pressurized for convenience and efficiency.

- Provides exceptional protection for low displacement devices, including bourdon tube gauges or electronic transmitters.

- Also suitable for high displacement devices like diaphragm, piston, or bellows-operated gauges, recorders, or controllers.

- Recommended for double-ported instruments such as Differential Pressure Gauges, advising a Model 150 installation on each input pressure line.

- Includes a Controlled Leak Check to safeguard against pressure spikes.

- Offers options for working pressures of either 5000 (340 bar) or 10000 (680 bar) PSIG.

Mid-West Model 200 Pressure Limiting Valve

- Model 200 “Gauge Minder” incorporates a pressure limiting valve to prevent over-pressurization, safeguarding against calibration errors and internal damage.

- Comes with three adjustable range springs, allowing shutoff pressure settings from 50 PSI (3.4 bar) to 5000 PSI (340 bar).

- Features an automatic shutoff valve that ensures a secure closure with no chattering, enhancing reliability.

- Valve reopens with just a 10% decrease from set pressure, eliminating the need for external reset.

- Ensures maintained accuracy of attached instruments until reaching the designated pressure shutoff point.

- Specifically designed for the protection of pressure gauges and transmitter components from overpressure situations.

- Aims to mitigate principal causes of instrument failure by controlling pressure range effectively.

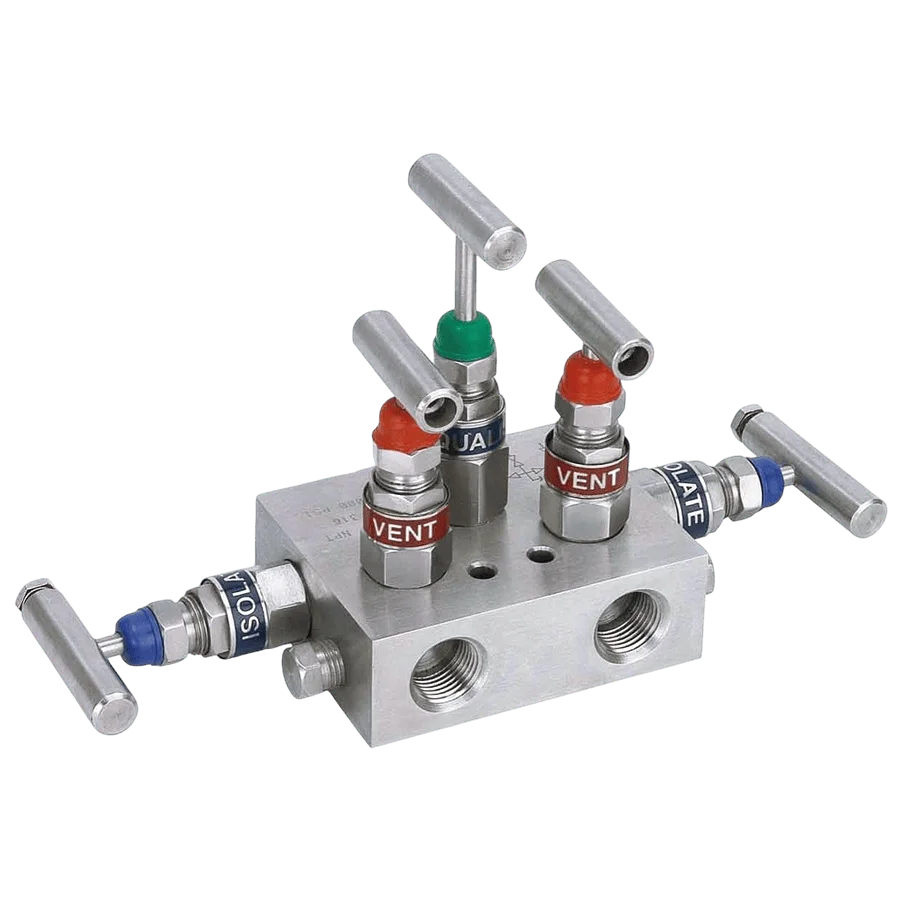

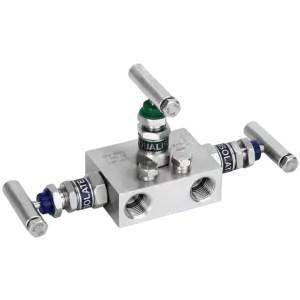

Mid-West Manifolds

- Rated for 6000 PSIG (414 bar) at 240°F (115°C).

- Instrument/Process connections: ½” FNPT standard, ¼” FNPT for 3-Valve Mini-Manifolds.

- Dust cap shields spindle threads from dirt and contamination.

- Gland Nut and Lock Nut adjust for leak-free operation, suitable for vacuums.

- Utilises PTFE packing with metal seal ring for assured leak-proof service.

- Machined bonnet ensures maximum reliability, extends valve lifespan, and protects against corrosion.

- Isolated stem threads with adjustable packing beneath stem for durable, leak-proof service.

- Design prioritises fewer parts to decrease leak points and emissions.

- Features ¼” FNPT test ports for convenient testing (excluding #113343 Mini-Manifold).

- Constructed with Teflon packing, stainless steel body, and integral seat for durability.

- 3 & 5 valve manifolds ideal for indirect instrument mounting, offering strong, compact, and leak-free performance verified by rigorous testing.