Celebrating 27 Years 1999-2026

CMC Technologies specialises in advanced explosion venting solutions, including self-reclosing explosion doors and reusable safety panels, designed for silos, filters, and ducts in food, feed, and bulk material industries. Our products offer adjustable activation pressures, durable construction, and cost-efficient maintenance for enhanced plant safety and operational reliability.

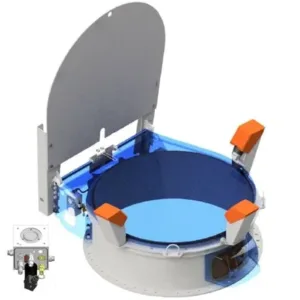

Thorwesten Vent FSL Explosion Doors

The increasing pressure in the explosion-threatened space, housing or container triggers the explosion door lid to open automatically. The explosion venting reduces the explosion overpressure.

The reduced explosion overpressure pred has a value higher than the static response pressure of the explosion door. The value pred which is reached depends on several factors and in the design of the explosion pressure venting concept it must be defined as the highest value to be able to carry out thecalculation of the required vent area for the respective application.

In the event of an explosion the hinged door lid opens once the retaining force of the retaining mechanism is overcome. The lid acceleration is sudden. The lid is therefore damped by a design feature which can withstand the kinetic energy which builds up in the accelerated lid. This kinetic energy is dissipated by a baffle plate.

Thorwesten Vent FLS Explosion Doors

Constructional explosion protection measures limit the occurring explosion pressure to a calculable level without causing significant damage to the process vessel. Conventional protective systems, however, allow the ingress of atmospheric oxygen. The resulting stack effect often leads to the burning out of large parts of the production plant. With a newly developed explosion protection door (type FSL/Food Super Light), Thorwesten Vent is launching a trend-setting alternative to conventional relief devices in food and feed production. Transport, drying, separation and storage of organic dusts such as starch, gluten, etc. make the danger of an explosion seem omnipresent. Comprehensive explosion protection is therefore of significant importance for product and plant safety.

Air-cushioned Explosion Doors TT Uni SL

Thorwesten Vent explosion doors for silos and ducts for explosion venting – self re-closing and re-usable.

- Distinctive constructional changes:

- retaining mechanism PCRM that works by means of pneumatic cylinder, time delayed, active reclosing of the explosion door’s lid

- heated explosion door’s lid made of fiber composite· heated vacuum breaker made of fiber composite

- Single-Baffle plate, as non-return stop plate

- Advantages

- Improved efficiency

- Activation pressure of retaining mechanism is variable adjustable

- Less space requirement during mounting (single non-return baffle plate)

- Replaceable temperature sensors (integrated in the explosion door’s lid)

- More resistant to environmental Influences and mechanical wear

- Simplification of mounting, commissioning and maintenance

- Extended possibilities of application

Air-cushioned Explosion Doors TT Uni K (Discontinued Model)

Thorwesten Vent explosion doors for silos and ducts for explosion venting – self re-closing and re-usable. Optional with integrated vacuum breakers.

This model has been discontinued.

Please refer to Air-cushioned Explosion Doors TT Uni SL above.

Air-cushioned Explosion Doors REL

Patented Thorwesten Vent explosion doors for explosion venting – self re-closing, for horizontal or vertical installation, e. g. in dust collectors.

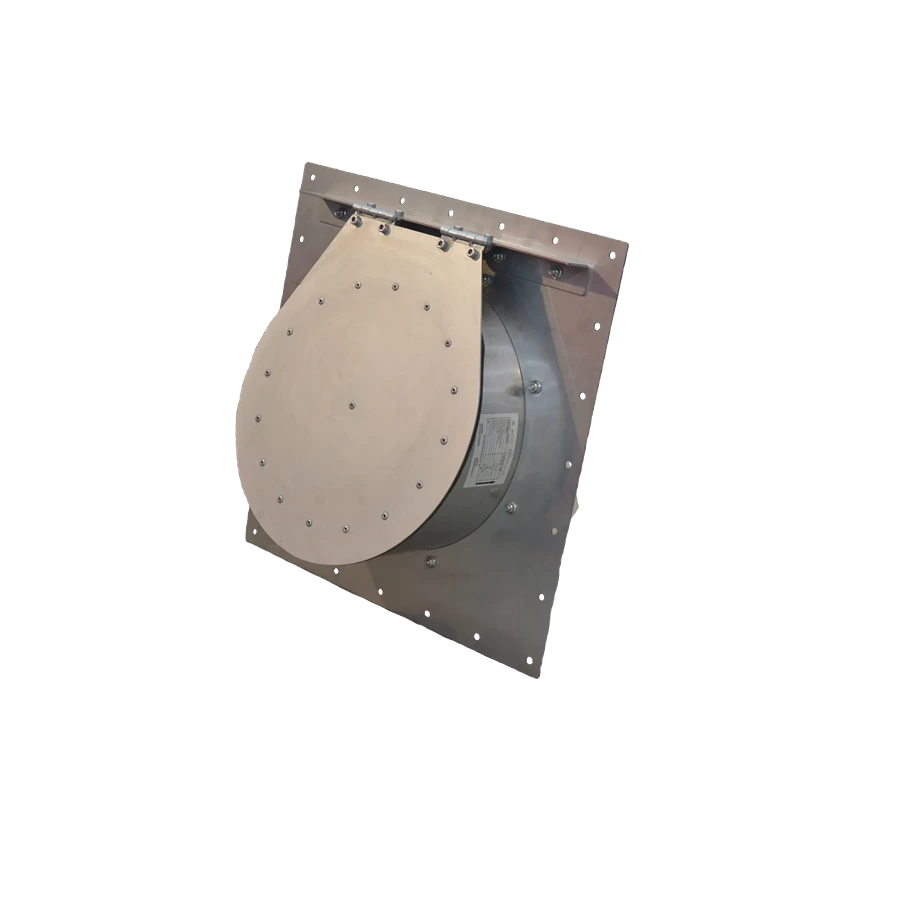

Re-usable Series (Par) Anti Explosion Panel

The PAR Series Re-Usable Safety Panel is an explosion safety device suitable for silos, mixers, sieves, filter separators, channels, pipes, dust collectors and dryers.

When an explosion occurs in the equipment connected to the Safety Panel and causes overpressure this pressure wave will activate the panel to give free outlet of overpressure from possible explosion to open space or protected zone with no damages at all.

They can be used repeatedly after each activation or explosion without need of parts replacement, making it very efficient cost wise.

Specifications

- Material: Available in Stainless Steel AISI 304 on request

- Working Conditions: Maximum working depression of 0.2 bar, operational temperature range of -10°C to +80°C

- Performance: KSTmax of 900 bar m/s, Pmax of 9 bar, Pred, max of 1.5 bar

- Design: Burst surface of 0.125 m², weight of 12.6 kg

Certification and Installation

- Certification: EN 14797 certified, DNV-MUNO 09 ATEX 4518 II D approved

- Installation: Designed for flat surfaces, suitable for VACUUM systems, positively activated overpressure, fixed to welded frames or directly on the container

- Maintenance: Easy re-closure and maintenance post-activation with a special oil seal ensuring normal operation integrity

WANT MORE TECHNICAL DETAILS? DOWNLOAD OUR DATASHEET.

To all industries in which inflammable bulk materials with fines content are stored and/or processed, Thorwesten Vent offers innovative products of well proven quality and functionality for the realisation of constructional explosion protection.

The range of products comprises of

- devices for explosion venting of silos, filters and other process vessels

- limited pressure shock resistant, explosion vent-equipped silos

- devices inhibiting accelerated flame front- and pressure shock propagation through ducts (explosion doors in strategically chosen positions) and devices out-diverting flame- and pressure shock effects from ducts (explosion diverters)