Celebrating 27 Years 1999-2026

Robecco Explosion Prevention Systems and Automation

CMC Technologies offers advanced smouldering fire detection, CO monitoring systems and automation system for explosion prevention in various industries.

Robecco Dryer Protection | RDP

- Advanced CO Monitoring System: Tailored for the Australian and New Zealand Dairy Industry, enhancing fire safety and operational efficiency.

- Proactive Fire Detection: Early smouldering fire detection significantly reduces risks associated with fires and explosions, protecting personnel, the environment, and production facilities.

- Mitigate Fire Risks: High drying temperatures and specific material characteristics can lead to dangerous smouldering fires; our system addresses these hazards effectively.

- Guideline Compliance: Our CO analysis technology aligns with VDI guideline 2263 part 7 and 7.1, ensuring adherence to industry standards for fire safety.

- Reliable Gas Analysis Technology: Utilizing proven gas analysis methods for early fire detection, our system offers peace of mind for operators.

- Enhanced Safety Measures: Continuous monitoring of Carbon Monoxide (CO) levels is crucial for preventing fire and explosion incidents in production processes.

- Specialised Applications: Ideal for monitoring smouldering fires in dryers, ensuring a safer working environment in dairy production facilities.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

Robecco Silo Automation | RSA

- Reliable Silo Automation: Robecco provides robust silo automation controls that ensure continuous operation and efficiency in production plants.

- Integrated Periphery Equipment: Seamlessly integrates filling stations, weighing units, conveyors, filters, and extraction systems into a cohesive control concept.

- Comprehensive Project Support: Robecco offers full project assistance, including engineering, commissioning, and training services to enhance operational success.

- Complete Control Solutions: The Robecco silo automation system features both hardware and software tailored for complete silo control, compatible with upper PLCs.

- Optimised Process Adaptation: Software and hardware are specifically optimised to match the unique requirements of each process, with adjustments made during the commissioning phase.

- Optional Product Integration: Enhance your system with optional products such as:

- Robecco G.A.S. (Gas Analysis System)

- Robecco Secure Center (Centralised Monitoring)

- Robecco Inert Control (Inert Gas Management)

- Robecco Dust Control (Dust Management Solutions)

- Comprehensive Monitoring and Control: The Robecco silo automation system effectively monitors and controls various processes and equipment, including:

- Analyser systems

- Temperature sensors

- Filling measurement systems

- Pressure sensors

- Exhaust filters

- Explosion vents

- Isolation equipment

- Filling stations

- Extraction systems

- Weighing units

- Quantity measuring units

- Inerting systems

- Earthing systems

- Enhanced Safety and Efficiency: Implementing Robecco silo automation ensures improved safety protocols and operational efficiency across all silo-related processes.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

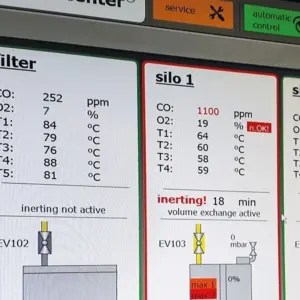

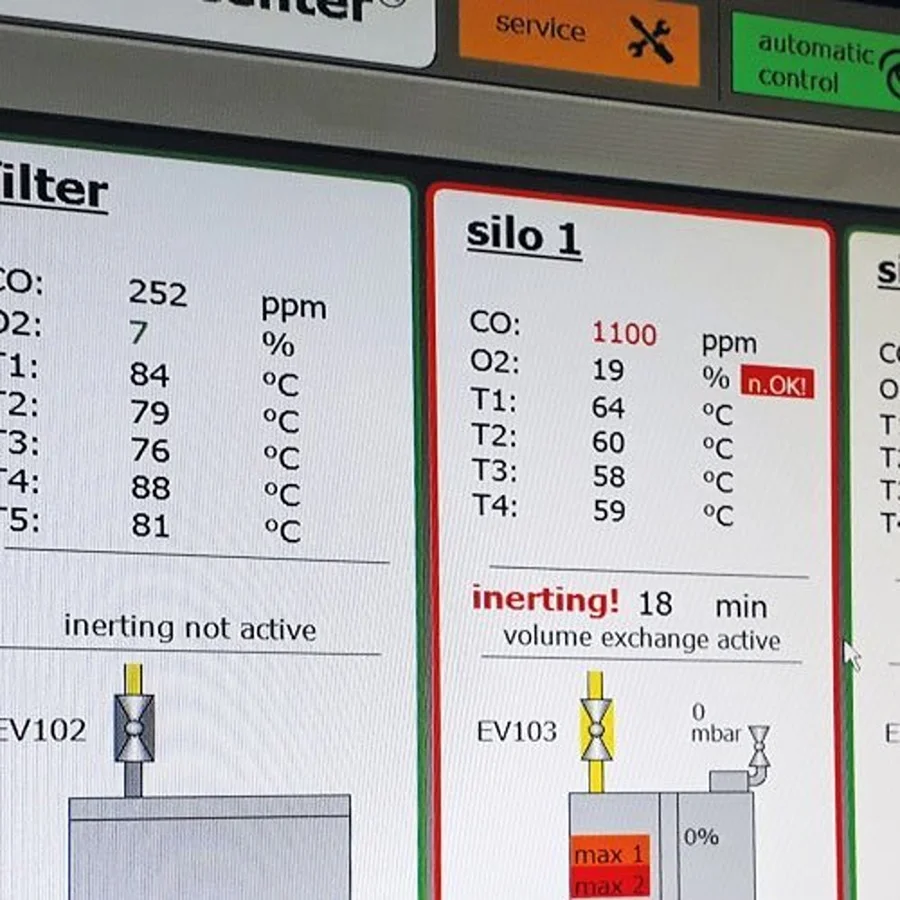

Robecco Inert Control | RIC

- Automated Inerting Control System: Robecco Inert Control (RIC) is a cutting-edge system designed for automated operation of inerting processes using CO2 or N2.

- Enhanced Explosion Protection: Effectively reduces limiting oxygen concentrations (LOC) to prevent explosions by purging inert gases into critical process atmospheres.

- Complete and Flexible Solutions: RIC offers a comprehensive solution tailored to various inerting system requirements, ensuring adaptability for different applications.

- User-Friendly Touchpanel Interface: Features an intuitive touchpanel for operation and visualization of plant conditions, allowing real-time monitoring of weights, filling levels, and valve limits.

- Proactive Failure Monitoring: All failure situations are continuously monitored, providing operators with immediate alerts to ensure swift responses to potential issues.

- Custom Engineering and Design: RIC is meticulously engineered to accommodate diverse processes, ensuring optimal performance across various industrial applications.

- Flexible Power Supply Options: Multiple power supply configurations allow for versatile installation and application in different environments.

- Comprehensive Project Support: Robecco provides full project assistance, including engineering, commissioning, and training services to ensure successful implementation and operation of the system.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

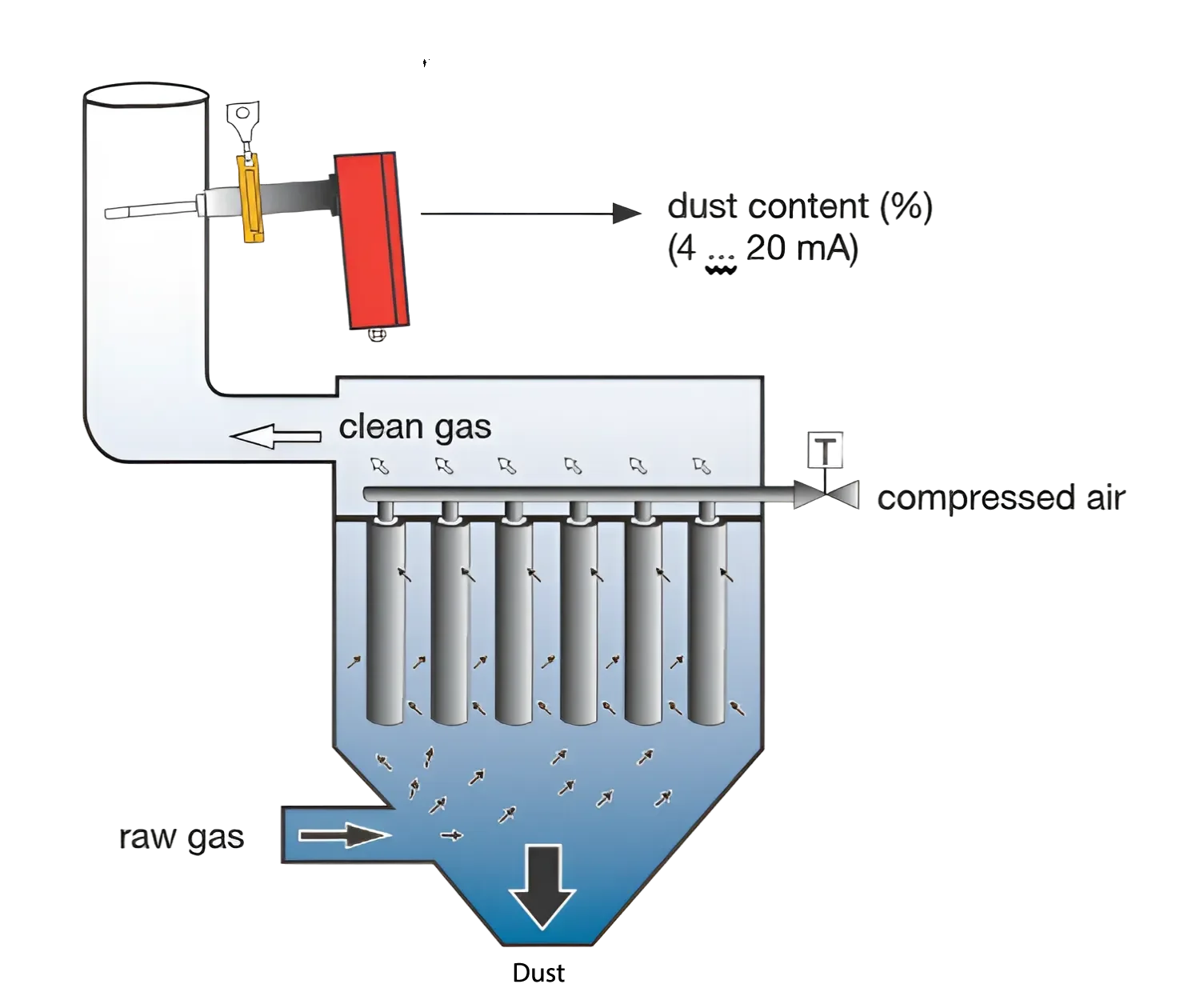

Robecco Dust Control | RDC | Filter System Control

- Essential Dust Emission Monitoring: Operating a modern filter system without continuous dust emission control is no longer feasible, ensuring compliance with regulatory standards and enhancing operational efficiency.

- Benefits for Operators: Continuous emission measurement and filter monitoring provide significant advantages, including minimised visible plumes and streamlined maintenance processes.

- Early Damage Detection: Utilizing a single device for emission measurement and filter monitoring allows for the early identification of filter damage, reducing downtime and maintenance costs.

- Targeted Maintenance Solutions: Quickly locate defective filter elements and implement targeted maintenance measures to maintain optimal filtration performance.

- Reduction of Product Losses: Effective monitoring and maintenance help avoid costly product losses due to filter inefficiencies or failures.

- Filter Controllers RDC 100C and RDC 200 ATEX: These advanced filter controllers are ideal for detecting effective damages in filtering precipitators, ensuring reliable operation in various environments.

- Triboelectric Measuring Principle: Employing the triboelectric measuring principle, which detects changes in particle transfer at conductive surfaces, ensures straightforward installation and user-friendly operation.

- Robust Performance: Designed to enhance the reliability and effectiveness of filtration systems, the RDC 100C and RDC 200 ATEX controllers provide critical insights for maintaining air quality standards.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!