Celebrating 27 Years 1999-2026

Spark Detection and Extinguishing

A spark detection and extinguishing system is a system using infrared detection and water mist in ducts to prevent fires and dust explosions.

T&B electronic’s spark and ember detection and extinguishing systems

T&B electronic’s spark and ember detection and extinguishing systems (represented exclusively in Australia and New Zealand by CMC Technologies) have been proven and approved by the independent German Insurance authority VdS since 1984. A spark detection and extinguishing system comprise infrared detection and water mist extinguishing in a duct prior to a filter / Dust collector or a process vessel or container that may have the perfect conditions to ignite a combustible cloud and cause a dust explosion or initiate a fire. To avoid damage to property and save lives, fires and explosions can be prevented by detecting and extinguishing one of the potential ignition sources in the material flow lines before they enter the enclosure.

WANT MORE TECHNICAL DETAILS? DOWNLOAD OUR DATASHEET.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

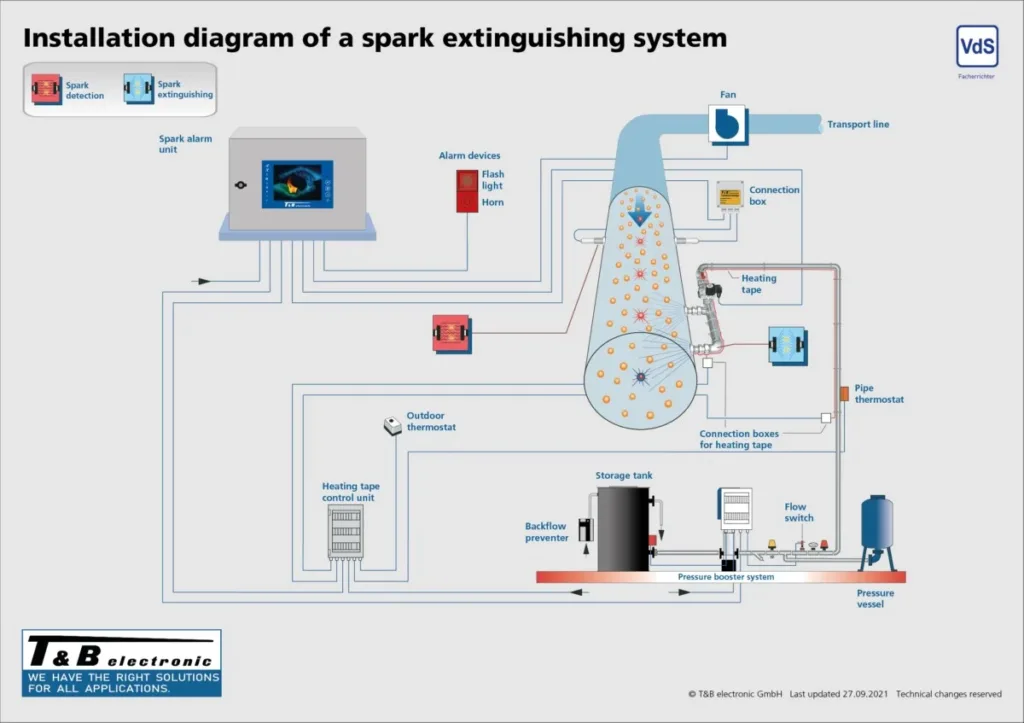

Spark extinguishing system Setup

Each application is different and the scope of protection can vary depending on the client’s requirements and acceptable residual risk. Tand B and CMC Technologies will work closely with you to create a holistic fire protection concept tailored to your requirements. In some cases where water mist is not desired, we can provide alternative isolation, diversion or even provide a fully automatic system in which the fire is detected and eliminated by oxygen displacement using for example an argon extinguishing system.

T and B electronic designs customized protection concepts and supplies fully-automated spark and ember extinguishing systems for the protection of filters, silos, processing machines, pneumatic suction systems, and many more production applications that are used in the following industries: recycling industry, wood flour – MDF, particle board, sawmills, sugar refining, bitumen, battery production, cotton wool and cotton seeds, chemicals, animal feed, flour mills, glass, rubber, coffee roasting, coal dust extraction, synthetic materials, power stations, food production, leather, metal processing, milk powder drying, waste incineration, paper mills, tire, chocolate production, tobacco, textile, pulp and paper and many more.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

Preventive Spark Detection and Extinguishing Systems in Material Processing Equipment

The processing of various materials can produce sparks, glowing hot particles (embers). The types of equipment that can produce these types of ignition sources are mills, grinders, saws, sanding machines, pellet presses, shredders, dryers, fans, and others. These machines are often connected to filters and cyclones where a fire or dust explosion can occur. The spark detection and extinguishing system is classified as a preventive system. It will reduce the risk of an explosion or fire occurring and many insurance companies provide a reduction in their premiums if such systems are used.

WANT MORE TECHNICAL DETAILS? DOWNLOAD OUR DATASHEET.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

Spark And Ember Detectors

NFPA 654 Appendix C provides basic but important information regarding the differences between various detectors. It covers park detector reliability, detector sensitivity and speed and provides emission spectra data of various sparks and embers by showing a diagram of the radiation intensity as a function of wavelength. With respect to Spark detector reliability in section C.1.2.1, it states as follow:

The first concern regarding a spark/ember detector is its ability to detect a spark, ember, or fire. NFPA 72 defines a spark as “a moving ember” and defines an ember as “a particle of solid material that emits radiant energy due either to its temperature or the process of combustion on its surface.

NFPA 654 Appendix C, section C.1.2.1.

Understanding Spark and Ember Detection Technologies for Duct Applications

Spark / Ember detectors are used in applications where there is motion or flow with a minimum speed in a duct. It is important to note that spark / ember detectors will work if the speed or velocity of the flow stream is not slow or above a threshold value. Silicone photocells or silicone photodiode detectors as they are also known operate in the short wavelength range and are sensitive to daylight. These detectors need to operate in darkness so that false or spurious alarms are not activated. Most ducting permits this, but some filters for example still use “plastic”, uncertified explosion vents filters, for example, can fatigue quickly or pinhole and allow light through, thus being one example of false system activation.

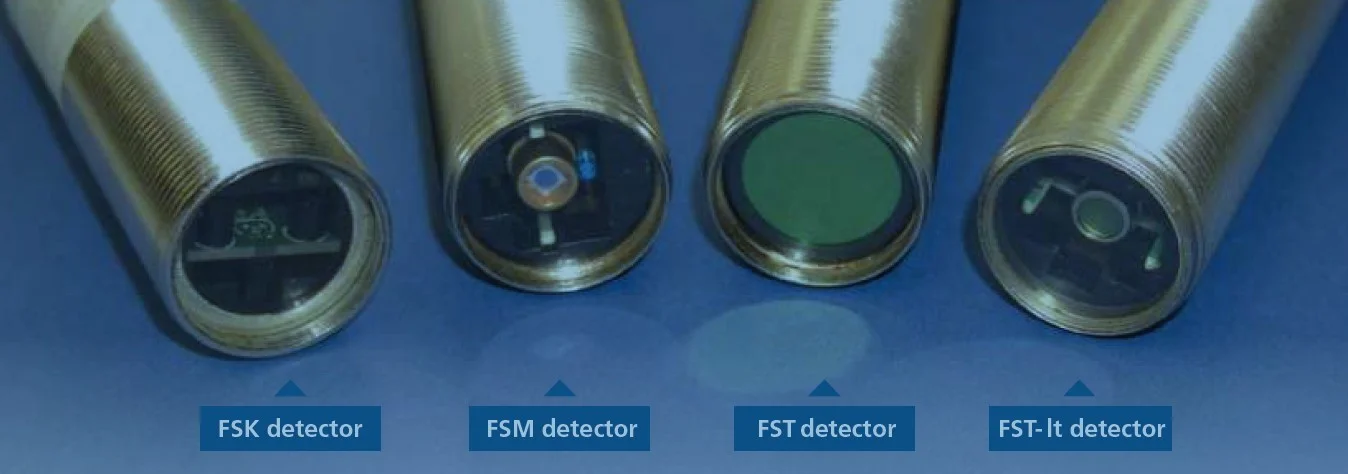

T & B Electronic has the most suitable detectors for different ignition sources, whether a hot particle detector type FST-lt, Ember detector type FST, Spark Detector type FSK, or our superior FSM combination detector type FSM. We are able to quote the right detector for different applications.

These high-performance and very sensitive Infrared detectors have been used in thousands of applications.

WANT MORE TECHNICAL DETAILS? DOWNLOAD OUR DATASHEET.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

IECEx Spark Detector and Connection Box

Check Out Our Different Types of Spark Detectors Video

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

Questions And Answers – FAQ – Frequently Asked Questions

𝟭. 𝗪𝗵𝘆 𝗶𝘀 𝘁𝗵𝗲 𝗩𝗲𝗹𝗼𝗰𝗶𝘁𝘆 𝗶𝗻 𝘁𝗵𝗲 𝗳𝗹𝗼𝘄𝗶𝗻𝗴 𝘀𝘁𝗿𝗲𝗮𝗺 𝗮𝗻 𝗶𝗺𝗽𝗼𝗿𝘁𝗮𝗻𝘁 𝗽𝗮𝗿𝗮𝗺𝗲𝘁𝗲𝗿 𝘁𝗼 𝗸𝗻𝗼𝘄 𝘄𝗵𝗲𝗻 𝗱𝗲𝘀𝗶𝗴𝗻𝗶𝗻𝗴 𝗮 𝘀𝗽𝗮𝗿𝗸 𝗲𝘅𝘁𝗶𝗻𝗴𝘂𝗶𝘀𝗵𝗶𝗻𝗴 𝘀𝘆𝘀𝘁𝗲𝗺?

The velocity in the duct in metres/second is used to calculate the separating distance between the installation of the detectors and the extinguishers. The response time of the system, as well as the water pressure and type of extinguishing nozzles, are then used to determine the separation distance. The faster the speed, the greater the distance, and the ideal speed typically in many applications is between 15 to 30 metres per second. The separation distances may vary from 5m to 10m or shorter. It is therefore important to provide a minimum to maximum velocity range so that the optimum system can be installed.

𝟮. 𝗪𝗵𝘆 𝗶𝘀 𝘁𝗵𝗲 𝗠𝗮𝘅𝗶𝗺𝘂𝗺 𝗼𝗽𝗲𝗿𝗮𝘁𝗶𝗻𝗴 𝘁𝗲𝗺𝗽𝗲𝗿𝗮𝘁𝘂𝗿𝗲 𝗼𝗳 𝘁𝗵𝗲 𝗳𝗹𝗼𝘄 𝘀𝘁𝗿𝗲𝗮𝗺 𝗶𝗺𝗽𝗼𝗿𝘁𝗮𝗻𝘁?

The maximum temperature resistance for an Infrared detector is 60 deg C. In the event of higher operating temperatures, the detector cannot be installed directly on the process. A fiber optic light conductor needs to be used. This will however reduce the viewing angle and depending on the duct size, the number of detectors to be used will need to be calculated.

𝟯. 𝗪𝗵𝗮𝘁 𝘁𝘆𝗽𝗲 𝗼𝗳 𝗱𝗲𝘁𝗲𝗰𝘁𝗼𝗿 𝘄𝗼𝘂𝗹𝗱 𝗯𝗲 𝘀𝘂𝗶𝘁𝗮𝗯𝗹𝗲 𝗳𝗼𝗿 𝘂𝘀𝗲 𝘁𝗼 𝗱𝗲𝘁𝗲𝗰𝘁 𝗮 𝗴𝗹𝗼𝘄𝗶𝗻𝗴 𝗲𝗺𝗯𝗲𝗿 𝗿𝗮𝗱𝗶𝗮𝘁𝗶𝗻𝗴 𝗲𝗻𝗲𝗿𝗴𝘆 𝗮𝘁 𝟰𝟬𝟬 𝗱𝗲𝗴 𝗖?

A silicon photocell detector will not be suitable in this instance as the operating wavelength does not cover the wavelength which a hot glowing particle at 400 deg c Radiates its energy. In this case, a lead sulphide detector type FST or Combination detector type FSM would be ideal. These detectors operate in the longer wavelength range to detect such glowing embers.

𝟰. 𝗦𝗵𝗼𝘂𝗹𝗱 𝗜 𝗯𝗲 𝗰𝗼𝗻𝗰𝗲𝗿𝗻𝗲𝗱 𝗶𝗳 𝗜 𝗶𝗻𝘀𝘁𝗮𝗹𝗹 𝗮 𝘀𝗶𝗹𝗶𝗰𝗼𝗻 𝗽𝗵𝗼𝘁𝗼𝗰𝗲𝗹𝗹 𝗱𝗲𝘁𝗲𝗰𝘁𝗼𝗿 𝗶𝗻 𝗮𝗻 𝗮𝗽𝗽𝗹𝗶𝗰𝗮𝘁𝗶𝗼𝗻 𝘄𝗵𝗲𝗿𝗲 𝘁𝗵𝗲 𝗠𝗜𝗧 – 𝗠𝗶𝗻𝗶𝗺𝘂𝗺 𝗶𝗴𝗻𝗶𝘁𝗶𝗼𝗻 𝘁𝗲𝗺𝗽𝗲𝗿𝗮𝘁𝘂𝗿𝗲 𝗼𝗳 𝘁𝗵𝗲 𝗰𝗼𝗺𝗯𝘂𝘀𝘁𝗶𝗯𝗹𝗲 𝗽𝗼𝘄𝗱𝗲𝗿/𝗱𝘂𝘀𝘁 𝗺𝗮𝘁𝗲𝗿𝗶𝗮𝗹 𝗶𝘀 𝗯𝗲𝗹𝗼𝘄 𝟱𝟬𝟬 𝗱𝗲𝗴 𝗖?

Yes. Unfortunately many applications over the last 30 years have silicon photocell detectors installed and these are only safe to use if the MIT of the combustible dust material is above 500 deg C as these would only detect red lighting sparks with a temperature above this threshold. If say the MIT is below 500 deg C such as wood flour, the ideal detector would be a long wave lead sulfide type FST or combination detector type FSM. Both will also detect red-lighting sparks as well as glowing embers.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!