Celebrating 27 Years 1999-2026

Process Monitoring For Woodworking Machines

T&B electronic delivers a complete system: spark detection, rapid extinguishing and optional IR process monitoring. We design a bespoke protection concept for your joinery, integrate alarms with your site systems, and supply full event documentation to the millisecond. The Spark Switch is available for an 8‑week free trial so you can assess real performance in your environment with no obligation.

Specifications

- Combined spark detection and extinguishing: optical and sensor-based detection located at machine outlets and in extraction lines, triggering high-pressure water mist or nozzle suppression in milliseconds.

- Infrared process monitoring (optional): continuous temperature monitoring of tools (saws, planers, milling heads) using specialised IR sensors to detect wear and overheating before sparks form.

- Two alarm stages: pre‑alarm for preventive action (tool change or maintenance) and main alarm for immediate extinguishing and escalation.

- External installation options: control units and electronics can be sited outside hazardous zones for simplified maintenance and extended component life.

- Alarm & integration: relay contacts and digital outputs forward alarms, faults and operating status to fire alarm panels, BMS or mobile alerts.

- Event logging: millisecond‑accurate records of detections, temperatures and system responses to assist investigations and insurance documentation.

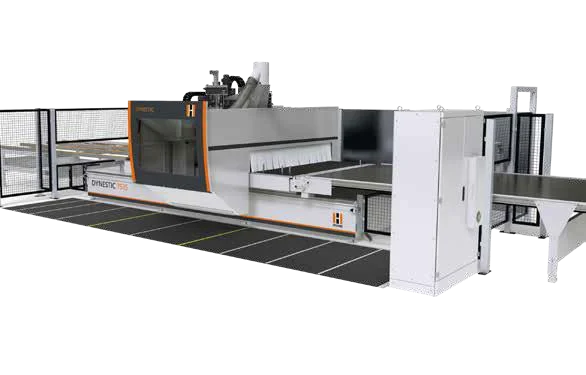

Common Applications

- Circular saws, planing machines, milling machines: detects sparks from tool failure, material kickback or foreign objects and extinguishes before dust ignites.

- Extraction systems and ductwork: early suppression of sparks entering ducts prevents spread and ignition in silos and downstream equipment.

- Sanding machines & paint booths: protects high‑risk areas where fine dust or flammable coatings increase fire potential.

- Dust silos and storage: prevents ignition of accumulated dust by intercepting sparks and glowing particles before they reach stored material.

- Predictive maintenance: IR temperature monitoring provides pre‑alarms for tool wear, reducing scrap and unexpected downtime.

WANT MORE TECHNICAL DETAILS? DOWNLOAD OUR DATASHEET.