Celebrating 27 Years 1999-2026

Advantages of EPI’s Thermal Mass Flow Meter (Flow Averaging Tube) for Combustion Air Flow

In industrial applications, accurate measurement of combustion air flow is essential for optimising efficiency and ensuring safety. EPI’s Thermal Mass Flow Meter, known as the Flow Averaging Tube (FAT Probe), stands out as a revolutionary solution designed to address the challenges faced in combustion air measurement. This blog post will discuss the advantages of EPI’s FAT Probe, highlighting its innovative features and how it enhances combustion air flow measurement in various industrial settings.

Understanding Combustion Air Flow Measurement

The Importance of Accurate Measurement

Combustion processes require precise control of air flow to maintain optimal combustion conditions. Inaccurate measurements can lead to:

- Inefficient Combustion: Insufficient or excessive air can result in incomplete combustion, wasting fuel and increasing emissions.

- Safety Hazards: Mismanagement of air flow can lead to dangerous situations, including explosions or equipment damage.

- Regulatory Compliance Issues: Industries must adhere to strict emissions regulations, making accurate measurement essential for compliance.

Given these challenges, employing advanced measurement technology is crucial for achieving reliable results.

Overview of EPI’s Thermal Mass Flow Meter (FAT Probe)

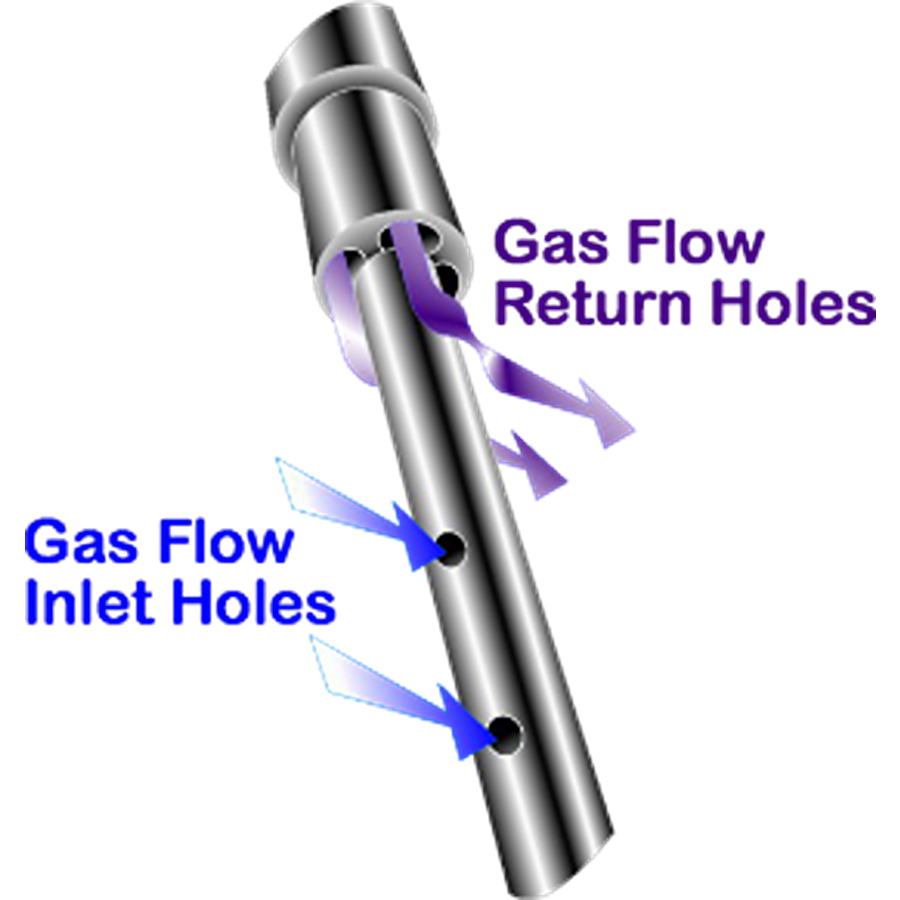

EPI’s FAT Probe combines the benefits of traditional flow measurement technologies into a single, efficient solution. Designed specifically for combustion air applications, this device offers unique features that set it apart from conventional sensors.

Key Features of EPI’s FAT Probe

- High Turndown Ratio:

- The FAT Probe boasts an impressive 100:1 turndown ratio. This allows for accurate measurements across a wide range of flow rates, making it suitable for various operating conditions.

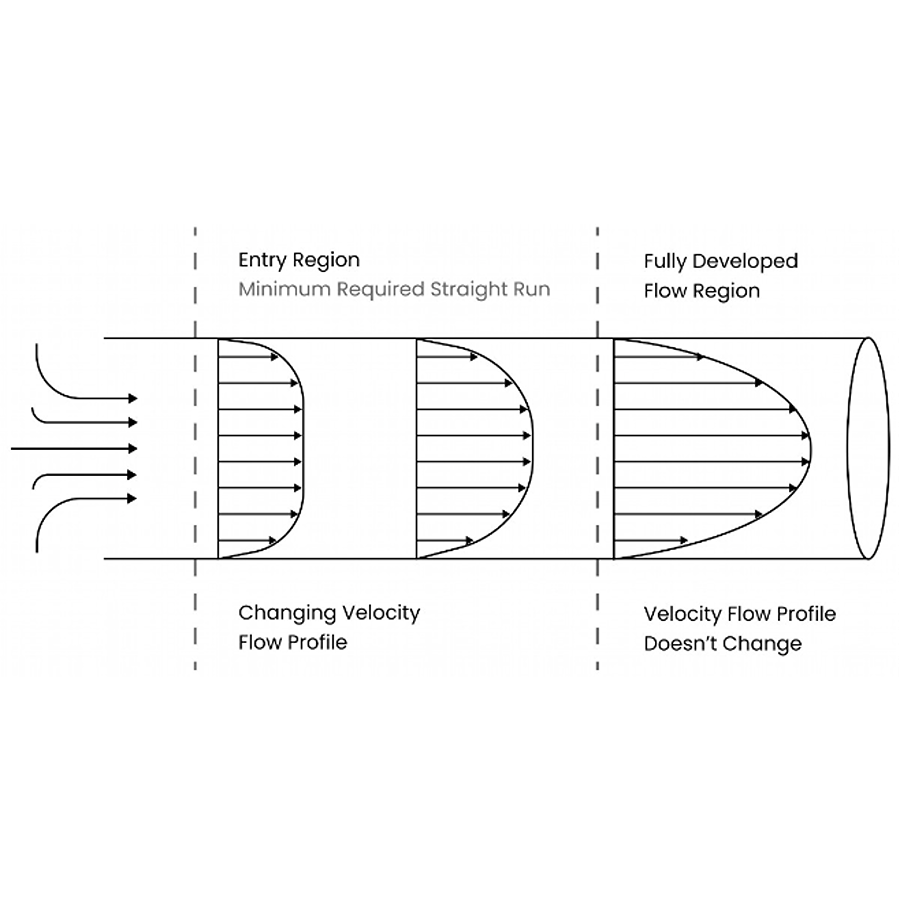

- Reduced Straight Run Requirements:

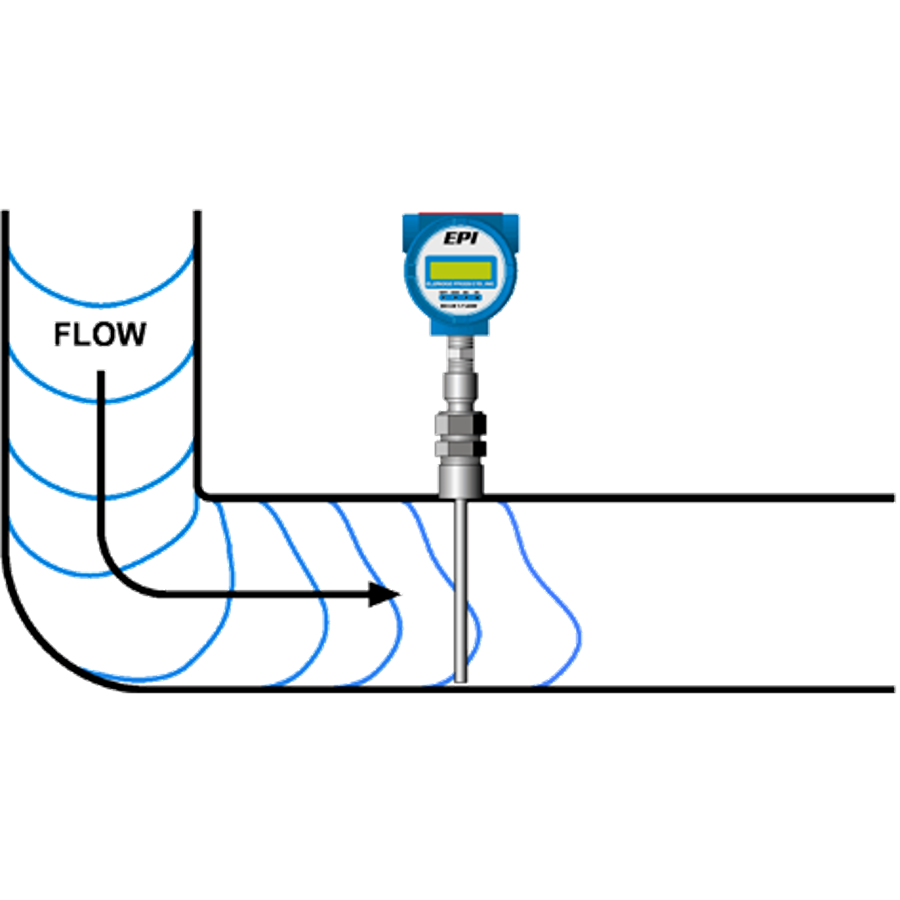

- Traditional measurement technologies often require significant straight pipe runs—typically 25 diameters or more. In contrast, the FAT Probe needs only 5 diameters, allowing for installation in tighter spaces and less disruption to existing systems.

- Direct Mass Flow Output:

- The FAT Probe provides direct mass flow readings, eliminating the need for complex calculations associated with volumetric flow measurements. This simplifies data interpretation and enhances operational efficiency.

- Multiple Sensing Points:

- The design incorporates multiple sensing points across the flow profile, ensuring accurate measurements even when the flow profile is not fully developed. This feature is crucial in large ducts where conventional single-point sensors may fail.

Combustion Flow Measurement Opportunities

The need for effective combustion flow measurement solutions presents numerous opportunities across industries, especially in natural gas submetering applications. While fuel gas can be measured using various existing technologies, the challenge lies primarily with combustion air measurement. For decades, traditional methods have struggled to deliver reliable results due to factors such as the large size of ducts, limited straight run requirements, and turndown constraints.

This gap in measurement technology highlights the significance of focusing on combustion air flow applications. With increasing competition in the market, solutions like EPI’s FAT Probe provide a timely and effective response to these long-standing challenges.

Advantages of EPI’s FAT Probe in Combustion Air Flow Applications

1. Enhanced Accuracy

The combination of high turndown capability and multiple sensing points means that the FAT Probe delivers precise measurements across varying conditions. This accuracy is essential for maintaining optimal combustion processes, reducing fuel waste, and minimising emissions.

2. Installation Flexibility

With lower straight run requirements compared to traditional devices, the FAT Probe can be easily integrated into existing systems without extensive modifications. This flexibility reduces installation time and costs while minimising downtime during retrofitting.

3. Improved Safety

Accurate measurement of combustion air flow contributes significantly to safety. By ensuring that the right amount of air is supplied for combustion, the FAT Probe helps prevent hazardous situations that could arise from improper air-fuel ratios.

4. Cost Efficiency

The FAT Probe’s ability to provide direct mass flow readings simplifies the monitoring process, allowing operators to quickly identify inefficiencies and make necessary adjustments. This leads to reduced operational costs and improved overall system performance.

5. Regulatory Compliance

Industries face increasing pressure to comply with emissions regulations. EPI’s FAT Probe helps ensure that combustion processes remain within acceptable limits by providing precise measurements necessary for compliance reporting.

EPI’s Thermal Mass Flow Meter (FAT Probe) represents a significant advancement in combustion air flow measurement technology. With its high turndown ratio, reduced straight run requirements, and ability to provide direct mass flow output, the FAT Probe addresses many challenges faced by industries today. By enhancing accuracy, installation flexibility, safety, cost efficiency, and regulatory compliance, the FAT Probe stands as an essential tool for optimising combustion processes.

As industries continue to seek ways to improve efficiency and reduce environmental impact, EPI’s FAT Probe plays a crucial role in achieving these goals. By focusing on overcoming the historical challenges of combustion air measurement, this innovative solution becomes a valuable asset in modern industrial applications, ensuring that businesses can navigate the complexities of energy use effectively while maintaining operational excellence.

For companies seeking expert solutions in combustion air flow measurement, CMC Technologies proudly represents EPI in Australia and Oceania. Our team is dedicated to providing support and guidance for your specific applications. If you require advanced measurement devices like the Thermal Mass Flow Meter (FAT Probe), please do not hesitate to contact us. We are here to assist you in achieving optimal performance with cost effectiveness and compliance in your operations.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!