Celebrating 27 Years 1999-2026

Differential Pressure Instruments For Flow

SKI offers DP flow measurement of gases, liquids and steam based on the international standard ISO 5167.

Differential Pressure Instruments For Flow (According to ISO 5167)

ISO 5167-compliant differential pressure instruments are used in the majority of industrial sectors. The variety of throttling devices and materials available allows for the measurement of a wide range of fluids at varying flow rates, temperatures, and pressures.

Because of their standardisation, the expected measurement results are manufacturer-independent.

The ISO 5167 standard provides detailed descriptions of the design features, constraints, and error limits of the various differential pressure flow elements. The application area includes technical gases, compressed air, fresh and combustion air, steam/heat quantities, heat transfer fluids and water.

The following is a general description of the various elements SKI offers.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!

Differential Pressure Instruments

Orifice Plates With Integral Taps

- Cost effective, single body.

- Two pressure tapping points.

- Easy installation.

- Good accuracy, reasonable inlet/outlet runs.

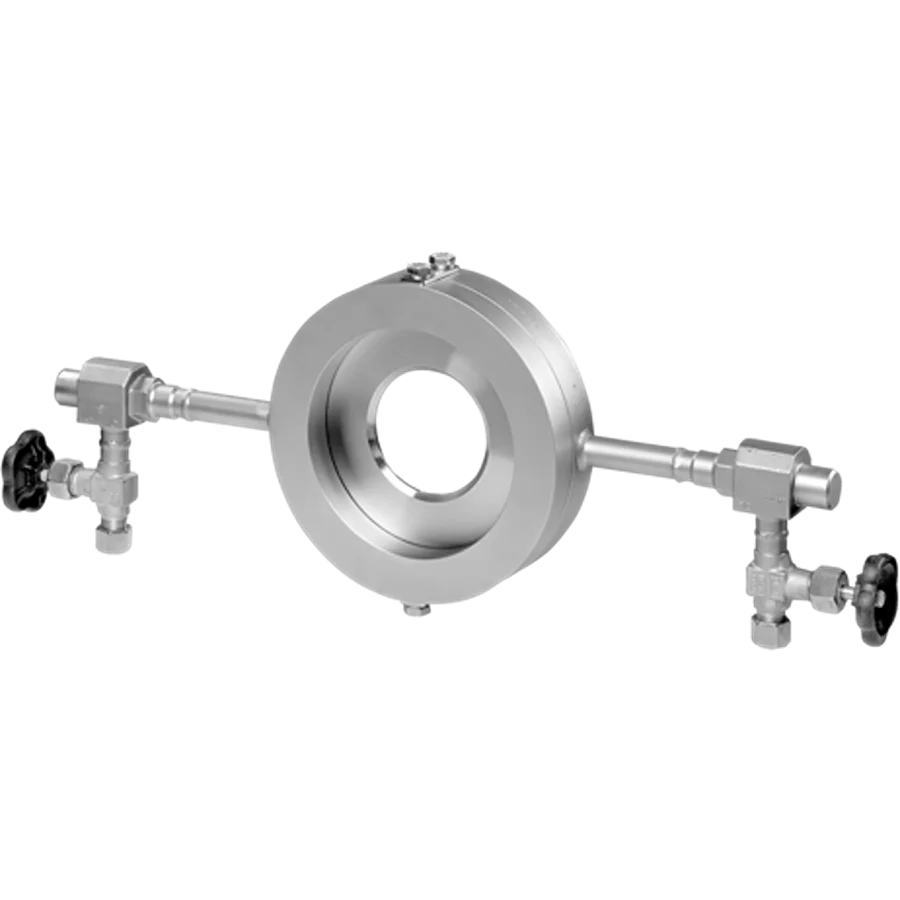

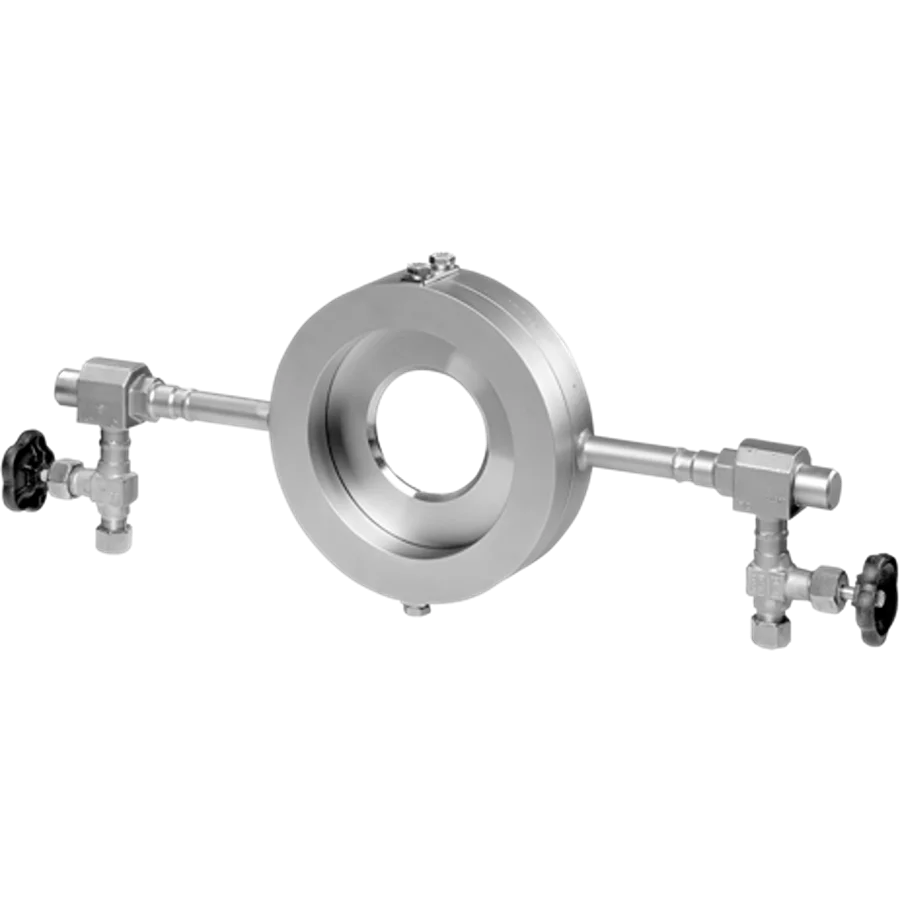

Orifice Plates With Annular Chambers

- Clamped between annular chamber rings.

- Pressed between standard pipe flanges.

- Pressure measured upstream and downstream.

- Accuracy comparable to standard orifice.

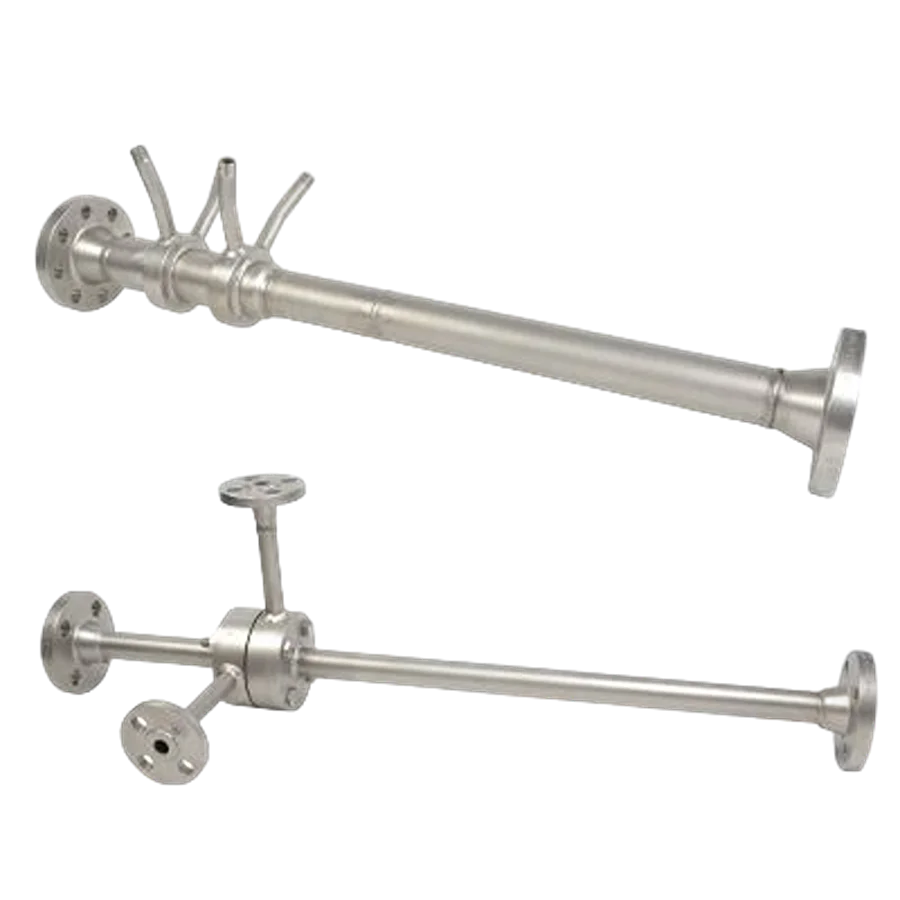

Meter Runs

- Differential pressure element with inlet/outlet pipe sections.

- Used for small pipelines.

- Pipe tolerances impact measurement accuracy.

- Typically uses annular chamber orifice plate.

Orifice Plates

- Orifice plate with welded-on handle.

- No pressure taps.

- Mounted between flanges.

- Flanges contain ½” NPT pressure taps.

Nozzles

- Two categories: ISA 1932 nozzles and long radius nozzles.

- ISA 1932: high accuracy, low pressure loss, used in power plants, multiple tap designs.

- Long radius: similar applications, excellent abrasion resistance, poorer linearity.

- Same design options as ISA 1932 nozzles.

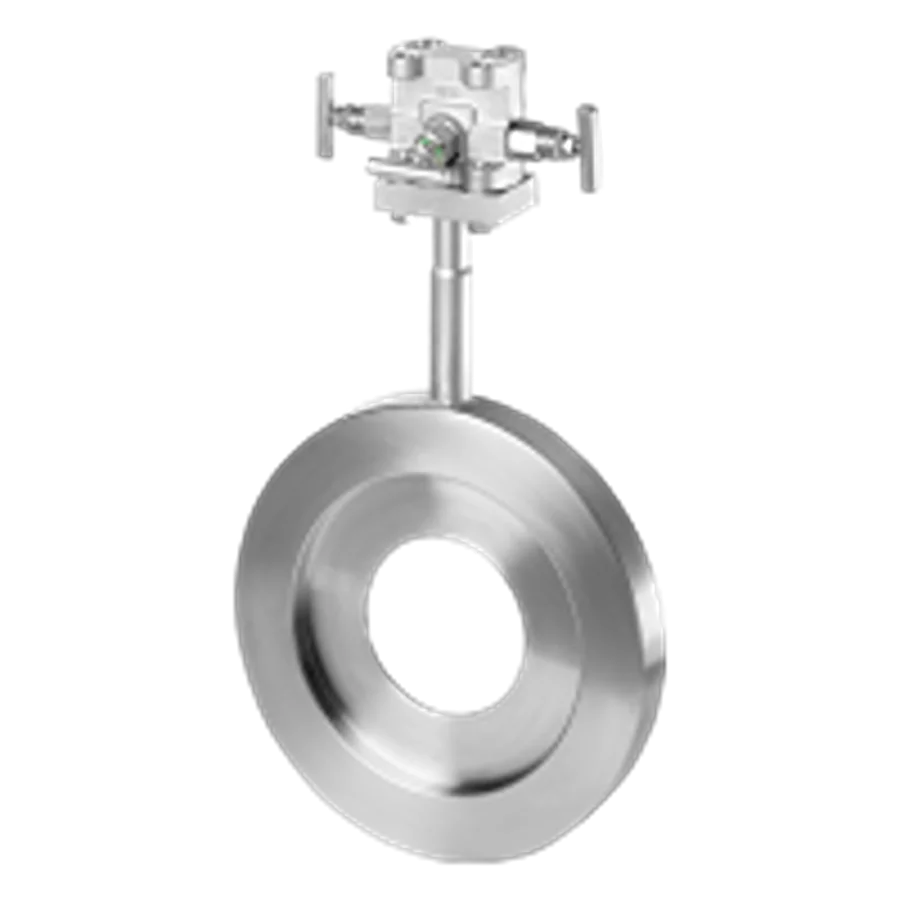

Venturi Nozzles

- Suitable for gases, steam, liquids.

- Good accuracy, low pressure loss.

- Excellent wear resistance, reduced linearity.

- Tap designs: corner, annular, flange ring, socket ring.

Classical Venturi Tubes

- Differential pressure elements.

- Very low permanent pressure losses.

- Used in short straight pipe runs.

- Good measuring accuracy.

- Tap designs: corner, annular chamber.

Cone Flow Meters

- Pipe section with a welded cone.

- Cone size increases with flow direction.

- Used in short pipe run applications.

- Most inaccurate in ISO 5167 ( ±5%\pm 5\% error).

- Good accuracy when laboratory calibrated.

WANT MORE TECHNICAL DETAILS? DOWNLOAD OUR DATASHEET.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!